A sucrose biosensor chip with specific isoforms

A biosensing and sucrose technology, which is applied in the field of preparation of sucrose biosensing chips, can solve the problems of unfavorable daily detection, cumbersome steps, and long detection cycle, and achieve the effects of accelerating electron transmission rate, avoiding enzyme pollution, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a sucrose biosensing chip with a specific configuration, comprising the following preparation steps:

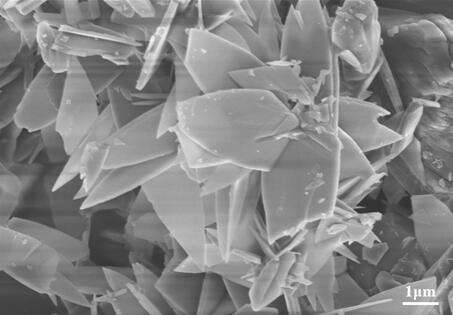

[0029] (1) Configure 10mM CuSO 4 Solution and the melamine solution of 5mM are mixed in equal volumes, and the mixed solution is centrifuged with a centrifuge, the centrifugation rate is 6000r / min, and the centrifugation time is 30min to obtain the copper melamine complex nano-slurry;

[0030] (2) the copper melamine complex nano-slurry of synthesis is mixed with carbon slurry by mass ratio 1:1, and make it mix evenly, prepare copper melamine complex-carbon mixed slurry;

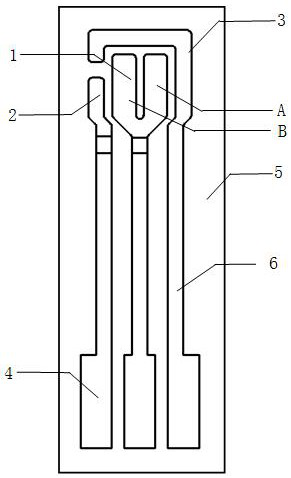

[0031] (3) if figure 2 As shown, the base electrode is printed on the bottom plate material by screen printing technology, and the working electrode area of area 1 has an area of 0.15cm 2 , the slurry used for printing is the copper melamine complex-carbon mixed slurry prepared in step 2); the area 2 reference electrode area has an area of 0.05cm 2 , the paste used fo...

Embodiment 2

[0036] A method for preparing a sucrose biosensing chip with a specific configuration, comprising the following preparation steps:

[0037] (1) Configure 20mM CuSO 4 Solution and the melamine solution of 40mM are mixed in equal volumes, and the mixed solution is centrifuged with a centrifuge, the centrifugation rate is 8000r / min, and the centrifugation time is 15min to obtain the copper melamine complex nano-slurry;

[0038] (2) the copper melamine complex nano-slurry of synthesis is mixed with carbon slurry by mass ratio 1:9, and make it mix evenly, prepare copper melamine complex-carbon mixed slurry;

[0039] (3) if figure 2 As shown, the base electrode is printed on the bottom plate material by screen printing technology, and the working electrode area of area 1 has an area of 0.15cm 2, the slurry used for printing is the copper melamine complex-carbon mixed slurry prepared in step 2); the area 2 reference electrode area has an area of 0.05cm 2 , the paste used fo...

Embodiment 3

[0044] A method for preparing a sucrose biosensing chip with a specific configuration, comprising the following preparation steps:

[0045] (1) Configure 10mM CuSO 4 Solution and the melamine solution of 50mM are mixed in equal volumes, and the mixed solution is centrifuged with a centrifuge, the centrifugation rate is 12000r / min, and the centrifugation time is 5min to obtain the copper melamine complex nano-slurry;

[0046] (2) the copper melamine complex nano-slurry of synthesis is mixed with carbon slurry by mass ratio 1:49, and make it mix evenly, prepare copper melamine complex-carbon mixed slurry;

[0047] (3) if figure 2 As shown, the base electrode is printed on the bottom plate material by screen printing technology, and the working electrode area of area 1 has an area of 0.15cm 2 , the slurry used for printing is the copper melamine complex-carbon mixed slurry prepared in step 2); the area 2 reference electrode area has an area of 0.05cm 2 , the paste used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com