Preparation method for increasing resistant starch content of rice

A technology of resistant starch and rice, applied in the functions of food ingredients, protein-containing food ingredients, food science, etc., can solve the problems of high glycemic index, not diabetic patients, etc., to increase the content, delay diabetes complications, reduce The effect of the glycemic index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

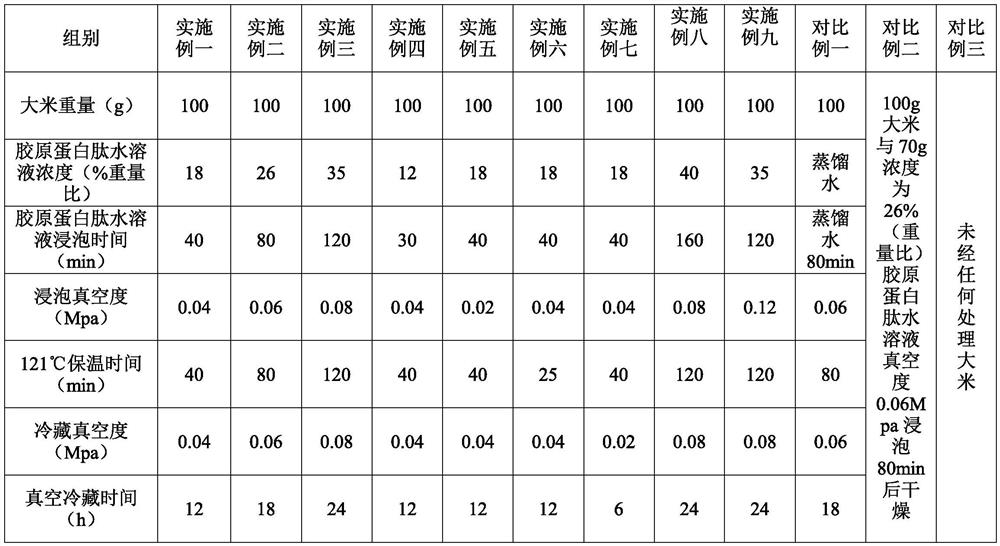

[0021] Improve the preparation method of rice resistant starch content, get 100g rice and place concentration and be in 18%~35% (weight ratio) collagen protein peptide aqueous solution, the weight ratio of rice and collagen protein peptide aqueous solution is 1: 0.7, in vacuum degree is Vacuum soak for 40-120 minutes under the condition of 0.04-0.08Mpa; take out the rice, put it in a high-pressure steam pot, heat it to 121°C and keep it warm for 40-120min, take it out and let it cool naturally, at a temperature of 4°C and a vacuum of 0.04-0.08Mpa Refrigerate under vacuum for 12-24 hours and dry.

[0022] According to the parameters in Table 1, according to the above preparation steps (wherein the weight ratio of rice and collagen peptide aqueous solution is 1:0.7), the first to ninth examples, and the first to third comparative examples were prepared.

[0023] Table 1

[0024]

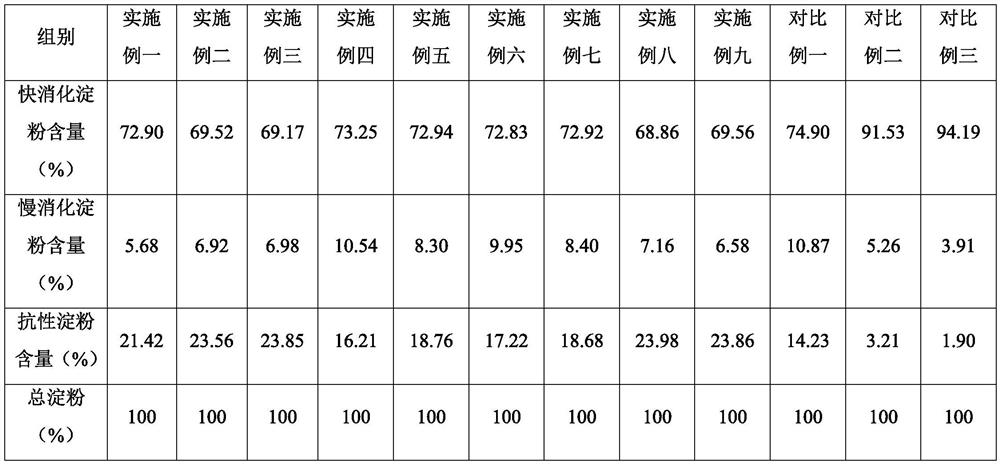

[0025] The contents of fast digestible starch, slow digestible starch and resistant starch in t...

Embodiment 8

[0040] The resistant starch content of the rice in Example 8 is equivalent to that of Examples 1-3. This is because when the concentration of the collagen peptide aqueous solution is low and the soaking time is short, increasing the concentration of the collagen peptide aqueous solution and the soaking time of the collagen peptide aqueous solution can promote the entry of the collagen peptide into the rice; but when the concentration of the collagen peptide aqueous solution and the collagen peptide After the soaking time of the protein peptide aqueous solution reaches a certain level, continue to increase the concentration and extend the soaking time. Since there is already a sufficient amount of collagen peptides in the rice, increasing the concentration and soaking time will not allow more collagen peptides to enter the inside of the rice. Therefore, the soaking time of rice in the collagen peptide aqueous solution is 40-120 minutes, and the concentration of the collagen pept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com