Preparation method of pea starch-emulsifier compound with high complexing index

A technology of pea starch and emulsifier, applied in the direction of food ingredients as emulsifiers, food science, function of food ingredients, etc., to achieve the effect of improving complexation index, increasing resistant starch content, and increasing the probability of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

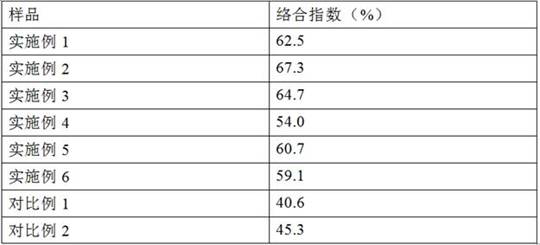

Examples

Embodiment 1

[0030] A preparation method of pea starch-monoglyceride citrate compound, comprising the following steps:

[0031] (1) Compound enzyme treatment of pea starch: add pea starch to sodium acetate buffer solution with a pH value of 7.0 to prepare a starch milk solution with a concentration of 6% by mass; heat the starch milk at 95°C for 30 minutes, and cool to 55°C, add 8U / g maltose amylase, enzymolysis for 30min, after hydrolysis, heat the mixed solution at 95°C for 10min to inactivate the enzyme; cool to 50°C, add 20U / g dextran branching enzyme, enzymolysis 40min, after hydrolysis, heat the mixed solution at 95°C for 10min to inactivate the enzyme.

[0032] (2) Pea starch debranching treatment: adjust the pH value of the hydrolyzed solution obtained in step (1) to 5.0, add 40U / g pullulanase at 55°C, debranch for 30min, and debranch at 95°C after debranching The mixed solution was heated for 10 min to inactivate the enzyme.

[0033] (3) Construction of pea starch-monoglyceride ...

Embodiment 2

[0037] A preparation method of pea starch-molecular distillation monoglyceride compound, comprising the following steps:

[0038] (1) Compound enzyme treatment of pea starch: add pea starch to sodium acetate buffer solution with a pH value of 6.8 to prepare a starch milk solution with a concentration of 8% by mass; heat the starch milk at 90°C for 45 minutes, and cool to 55°C, add 12U / g maltose amylase, enzymatically hydrolyze for 40min, heat the mixed solution at 90°C for 15min after hydrolysis; cool to 55°C, add 30U / g dextran branching enzyme, enzymolyze 30min, after hydrolysis, heat the mixed solution at 90°C for 15min to inactivate the enzyme.

[0039] (2) Pea starch debranching treatment: adjust the pH value of the hydrolyzed solution obtained in step (1) to 4.7, add 45U / g pullulanase at 58°C, debranch for 45min, and debranch at 90°C after debranching The mixed solution was heated for 15 min to inactivate the enzyme.

[0040] (3) Construction of pea starch-molecularly d...

Embodiment 3

[0044] A preparation method of pea starch-diacetyl tartrate monoglyceride compound, comprising the following steps:

[0045](1) Compound enzyme treatment of pea starch: add pea starch to sodium acetate buffer solution with a pH value of 7.0 to prepare a starch milk solution with a concentration of 9% by mass; heat the starch milk at 90°C for 50 minutes, and cool to 50°C, add 16U / g maltose amylase, enzymatically hydrolyze for 35min, heat the mixed solution at 95°C for 10min after hydrolysis; cool to 50°C, add 25U / g dextran branching enzyme, enzymolyze 40min, after hydrolysis, heat the mixed solution at 95°C for 10min to inactivate the enzyme.

[0046] (2) Pea starch debranching treatment: adjust the pH value of the hydrolyzed solution obtained in step (1) to 4.5, add 35U / g pullulanase at 60°C, debranch for 50min, and debranch at 95°C after debranching The mixed solution was heated for 10 min to inactivate the enzyme.

[0047] (3) Construction of pea starch-diacetyl tartaric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com