Preparation method of electroplating-grade potassium pyrophosphate

A technology of potassium pyrophosphate and electroplating grade, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., and can solve problems such as increased production costs, high production energy consumption, and uneven heating of dipotassium hydrogen phosphate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

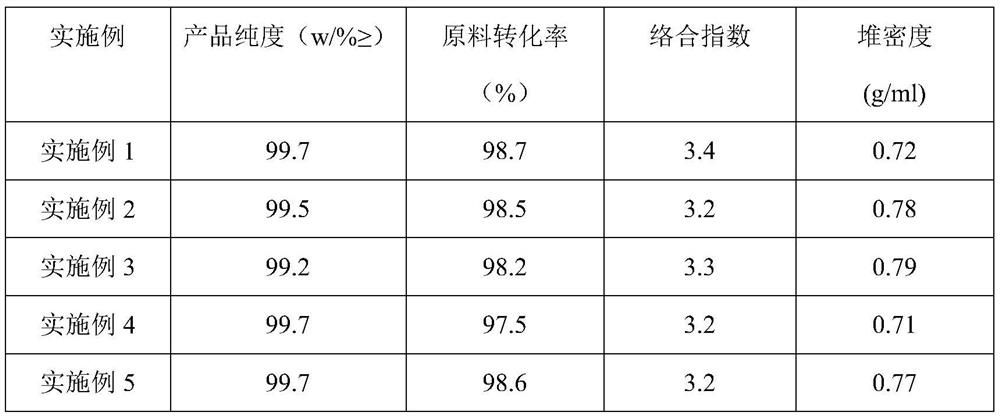

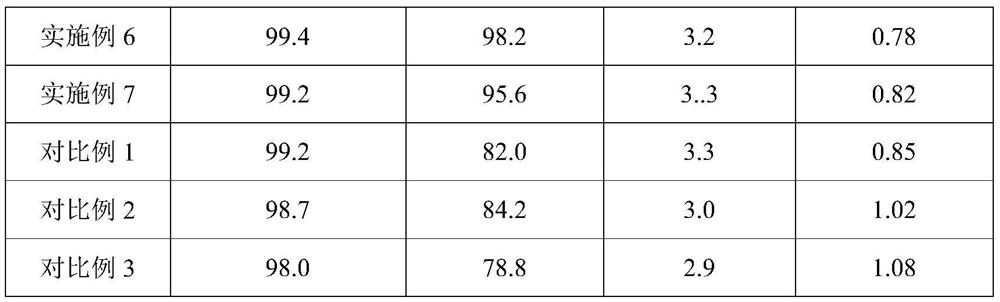

Examples

Embodiment 1

[0029] (1) 11.5 tons of 85wt% phosphoric acid aqueous solution and 23.4 tons of 48wt% potassium hydroxide aqueous solution were neutralized and reacted, the reaction temperature was 90~95° C., and the pH of the neutralizing solution was controlled at 8.3~8.7 to obtain dipotassium hydrogen phosphate solution.

[0030] (2) Evaporating and concentrating the obtained dipotassium hydrogen phosphate solution to obtain dipotassium hydrogen phosphate crystal slurry with a water content of 30 wt%.

[0031] (3) The wet dipotassium hydrogen phosphate crystal is sent to a microwave belt drying line by a conveyor belt for microwave drying to obtain a dipotassium hydrogen phosphate solid. The drying power is 27KW, the heating temperature is 100° C., and the time is 1.5 to 2 hours.

[0032] (4) Send the dried dipotassium hydrogen phosphate solid through a conveyor belt into a microwave high-temperature kiln for polymerization to obtain potassium pyrophosphate. The heating power is 58.5KW, the...

Embodiment 2

[0035] (1) 11.5 tons of 85wt% phosphoric acid aqueous solution and 23.4 tons of 48wt% potassium hydroxide aqueous solution were neutralized and reacted, the reaction temperature was 90~95° C., and the pH of the neutralizing solution was controlled at 8.3~8.7 to obtain dipotassium hydrogen phosphate solution.

[0036] (2) Evaporating and concentrating the obtained dipotassium hydrogen phosphate solution to obtain dipotassium hydrogen phosphate crystal slurry with a water content of 30 wt%.

[0037] (3) The wet dipotassium hydrogen phosphate crystal is sent to a microwave belt drying line by a conveyor belt for microwave drying to obtain a dipotassium hydrogen phosphate solid. The drying power is 27KW, the heating temperature is 80° C., and the time is 1.5 to 2 hours.

[0038] (4) Send the dried dipotassium hydrogen phosphate solid through a conveyor belt into a microwave high-temperature kiln for polymerization to obtain potassium pyrophosphate. The heating power is 58.5KW, the ...

Embodiment 3

[0041] (1) 11.5 tons of 85wt% phosphoric acid aqueous solution and 23.4 tons of 48wt% potassium hydroxide aqueous solution were neutralized and reacted, the reaction temperature was 90~95° C., and the pH of the neutralizing solution was controlled at 8.3~8.7 to obtain dipotassium hydrogen phosphate solution.

[0042] (2) Evaporating and concentrating the obtained dipotassium hydrogen phosphate solution to obtain dipotassium hydrogen phosphate crystal slurry with a water content of 30 wt%.

[0043] (3) The wet dipotassium hydrogen phosphate crystal is sent to a microwave belt drying line by a conveyor belt for microwave drying to obtain a dipotassium hydrogen phosphate solid. The drying power is 27KW, the heating temperature is 120° C., and the time is 1.5 to 2 hours.

[0044] (4) Send the dried dipotassium hydrogen phosphate solid through a conveyor belt into a microwave high-temperature kiln for polymerization to obtain potassium pyrophosphate. The heating power is 58.5KW, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com