Ultrasonic preparation method of sagittaria sagittifolia RS5 type resistant starch and application in functional food

A kind of Cigu starch and ultrasonic technology, which is applied in the field of resistant starch preparation, can solve the problems such as the ultrasonic preparation method of Cigu starch RS5 type resistant starch and the like, and achieve the effects of good application prospect, high content and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

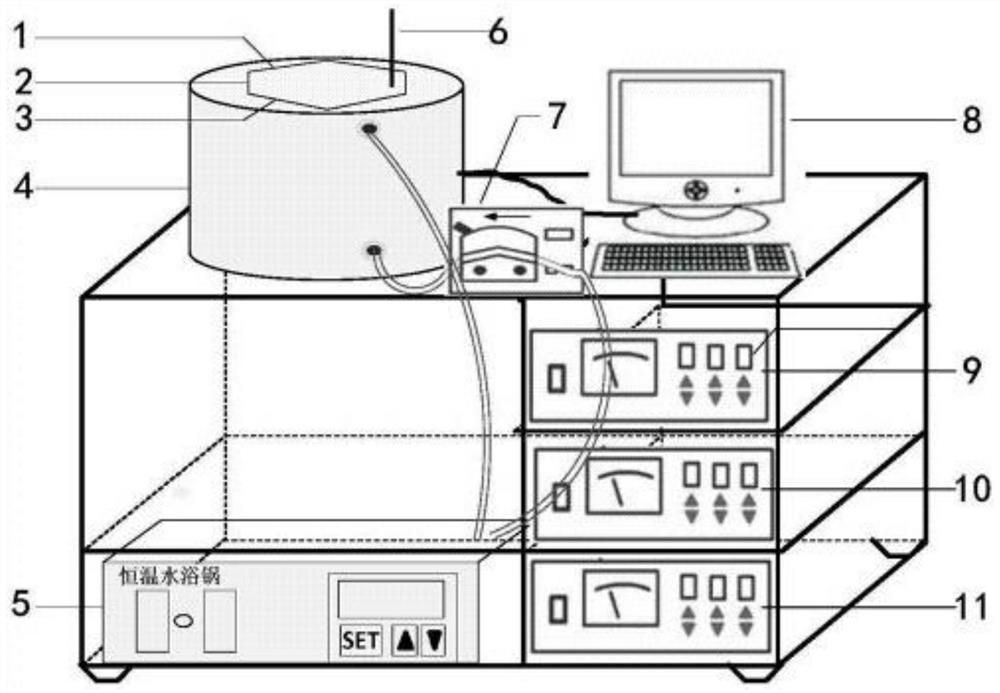

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of arrowroot starch, carries out according to the following steps:

[0059] (1) Soak Sagittarius in 4L of distilled water at 4°C for 12 hours;

[0060] (2) After peeling and cutting the arrowroot, use a mixer to pulverize it for 5 minutes;

[0061] (3) Dilute the slurry to 10 times with distilled water, then use NaOH solution to adjust the pH to 10.0;

[0062] (4) After the diluted slurry is magnetically stirred for 1 hour, filter through a 75-mesh sieve to remove fibers;

[0063] (5) Centrifuge the filtrate for 30 minutes (3000×g), discard the supernatant, and dry the white precipitate in an oven at 40°C to obtain Sagittarius starch, which is packaged;

[0064] (6) Measure the swelling power of the arrowroot starch prepared in step (5).

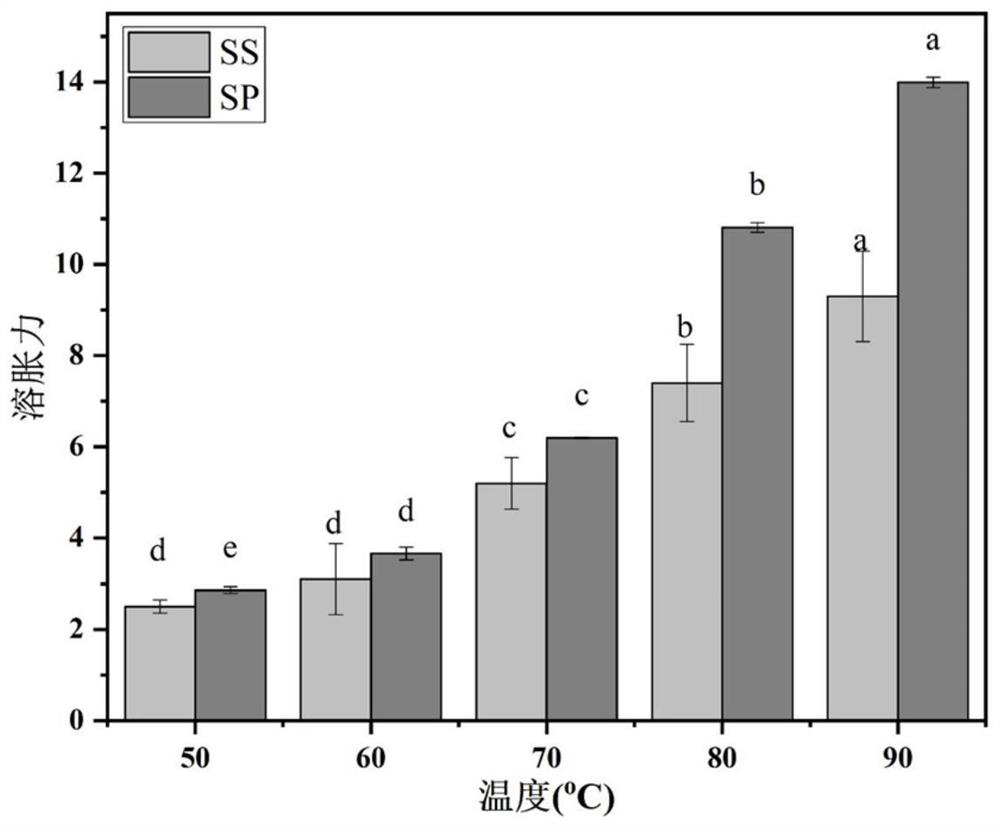

[0065] Determination of the swelling power of arrowroot starch: the swelling force of arrowroot starch is as follows: figure 2 shown. In the temperature range of 50°C to 90°C, its solubility and swelling p...

Embodiment 1

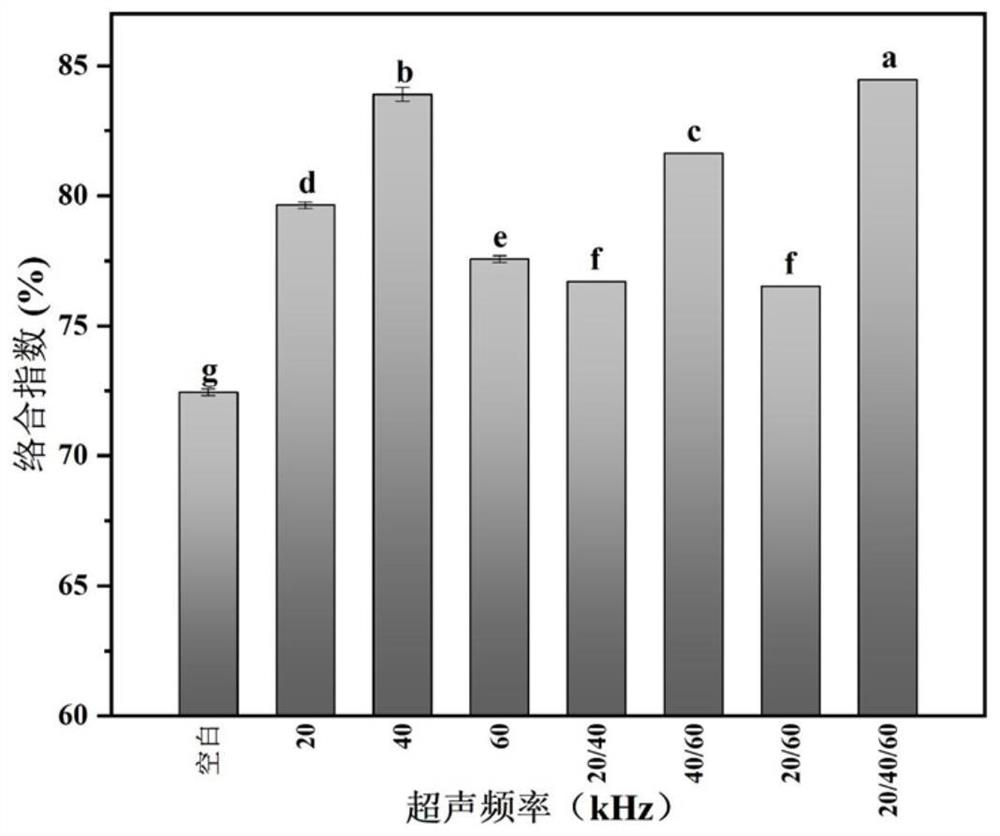

[0070] Embodiment 1: Preparation of Sagittarius starch-linoleic acid complex at different ultrasonic frequencies:

[0071] (1) After dissolving 0.3mL linoleic acid in 40mL of absolute ethanol, add it to 10% (m / v) sagittarius starch solution (6g sagittarius starch dispersed in 60mL distilled water), stir at 90°C for 30min, starch After the paste is cooled to room temperature, put it into a high-pressure resistant plastic airtight bag;

[0072] (2) Step (1) mixture is transferred to multi-frequency power ultrasonic equipment and carried out cold water bath ultrasonic treatment, ultrasonic time is 30min, ultrasonic power density is 300W / L, ultrasonic frequency (20kHz, 40kHz, 60kHz, 20kHz / 40kHz, 20kHz / 60kHz, 40kHz / 60kHz, 20kHz / 40kHz / 60kHz), the ultrasonic intermittent ratio is 10s / 4s;

[0073] (3) The mixture obtained in step (2) was centrifuged at 4000 rpm for 10 min, then washed and centrifuged three times with 50% ethanol solution to obtain a precipitate;

[0074] (4) drying...

Embodiment 2

[0079] Example 2: Preparation of arrowroot starch-stearic acid complex at different ultrasonic times

[0080] (1) Stir starch and stearic acid (10%, dry starch base) at 90°C for 20 minutes, and then put it into a high-pressure resistant plastic bag;

[0081] (2) Under the conditions of ultrasonic frequency 20 / 40kHz, ultrasonic power density 300W / L, ultrasonic time (20, 40, 60) min, ultrasonic intermittent ratio 10s / 4s, the mixture prepared in step (1) is Sonication in cold water bath;

[0082] (3) Centrifuge the sample prepared in step (2) for 10 min at 4000 rpm, then wash and centrifuge three times with 50% ethanol solution to obtain a precipitate;

[0083] (4) drying the precipitate obtained in step (3) in an oven at 40° C. for 24 hours to obtain the arrowroot starch-stearic acid complex prepared by ultrasound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com