One-size elastic shoe cover

A shoe cover and elastic technology, which is applied to shoe uppers, footwear, soles, etc., can solve the problems of three-dimensional size changes and affect the positive pressure of one-size-fits-all elastic shoe covers, and achieve small size, wide range of applicable sizes, and easy wearing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

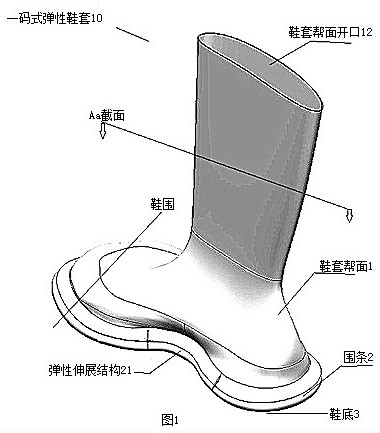

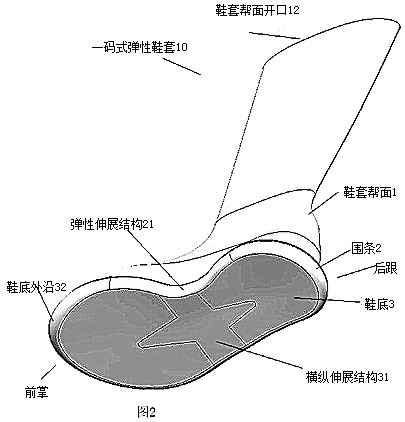

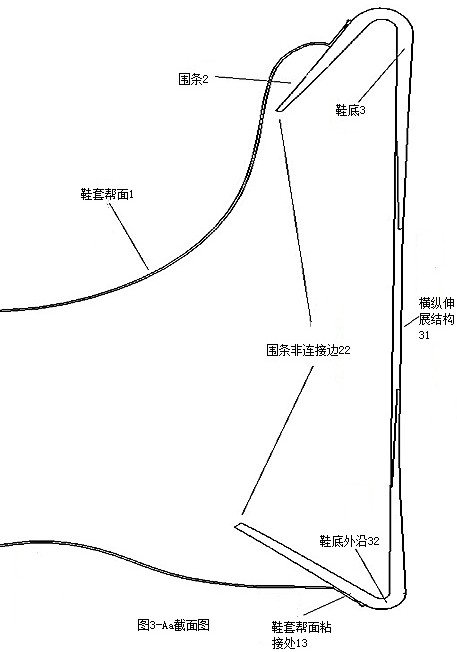

[0057] The present invention relates to a one-size-fits-all elastic shoe cover 10 . Further, the one-size elastic shoe cover 10 includes a one-size elastic shoe cover upper surface 1 with differentially distributed positive pressure, a shoe sole 3 that can be stretched horizontally and vertically, and a surrounding bar 2 that acts as a clamp. The one-size elastic shoe cover provided by the present invention is a one-size elastic shoe cover 10 with differentially distributed positive pressure, superior protection performance, high comfort and wide applicable size variation. It can perform three-dimensional adaptive wrapping according to the size change of the wearer's shoes. It is suitable for a wide range of shoes, flexible application, wear-resistant and practical, and high comfort. It will be appreciated by those skilled in the art that the present invention has particular application to shoes, but may also be used for other applications such as, but not limited to, dust pro...

Embodiment 2

[0063] Integrated injection molding of the apron sole.

[0064] With the one-yard elastic shoe cover 10 produced by the cold-glue gluing process, the problem of degumming and water leakage often plagues the user. In order to solve such problems, the process is further improved as follows: the integrated injection molding of the apron and the sole.

[0065] like Figure 5-10 As shown, the integrated design of the apron sole is injection molded through a mould. As is well known to those skilled in the art: elastic bands of the same material are loaded with the same elongation load, and when the cross-sectional area is different, the degree of deformation produced is different; the elastic band with a smaller cross-sectional area is stretched longer. Utilize this principle to design the one-size-fits-all elastic shoe cover 10, and achieve the effects of stretching, tightening and protection by adjusting the wall thickness in different regions. like Figure 5 As shown, located...

Embodiment 3

[0068] One-piece overmolding of the apron sole

[0069] It is difficult for one material to take into account all superior mechanical properties. Therefore, the apron and sole of the one-size elastic shoe cover 10 are further improved, and the apron and sole are integrated by a secondary molding process.

[0070] like Figure 11-17 As shown, the integrated sole of the bar is composed of a low modulus elastic soft body 4 and a high modulus protective hard body 5, and is formed by secondary injection molding. The one-size-fits-all elastic shoe cover 10 is made by welding the upper surface 1 of the shoe cover to the connection area between the outer edge of the shoe sole and the lower edge of the shoe cover through a welding process after the secondary molding is adopted for the integral type of the bar and sole. The one-yard elastic shoe cover 10 produced by this process has significantly improved wear resistance and anti-slip, elastic stretching and pressure-sensitive comfort....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com