Novel desorption equipment and desorption method

A desorption and equipment technology, which is applied in the field of organic waste gas treatment and environmental protection, can solve the problems of low service life of activated carbon and desorption equipment, inability to achieve effective recovery of soluble organic matter, high cost of desorption equipment and high operating costs, and reduce investment and Operating costs, small equipment footprint, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

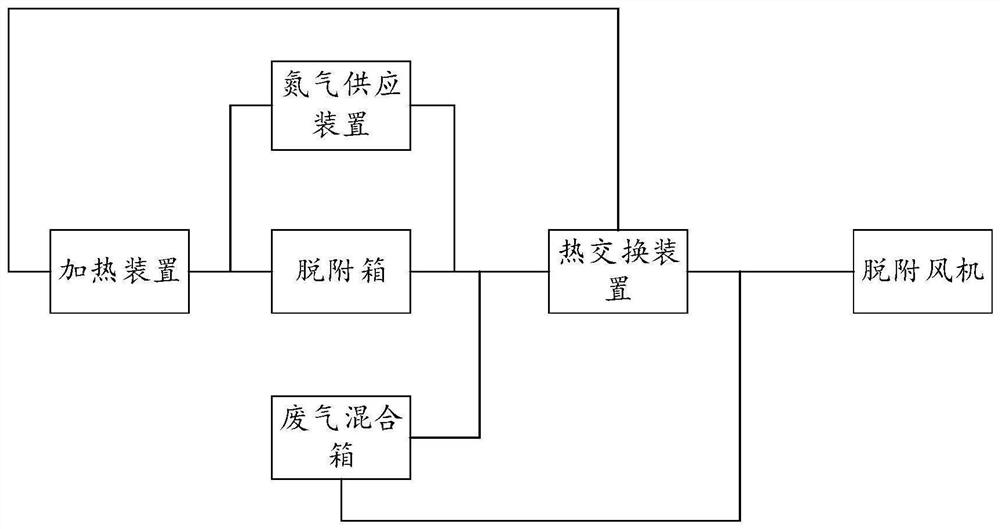

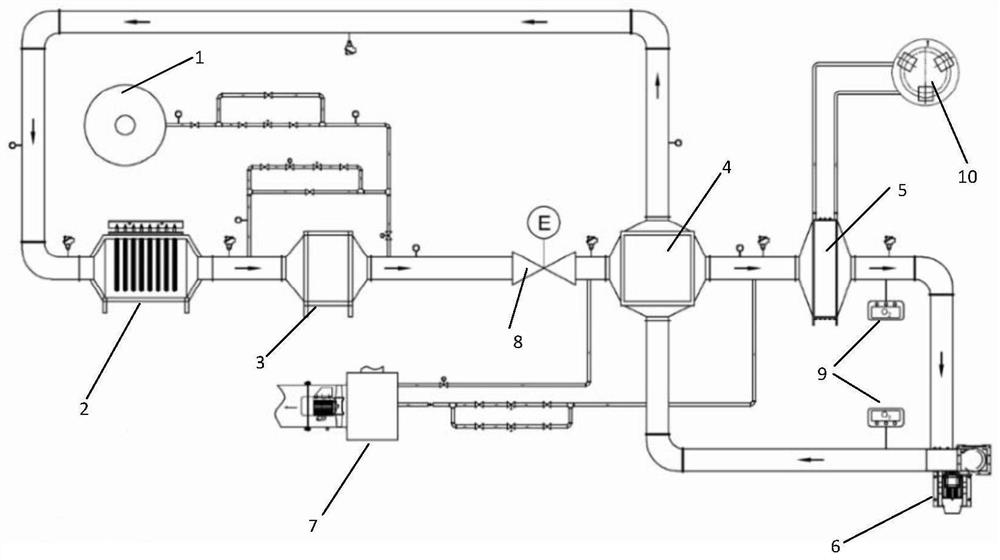

[0026] This embodiment provides a novel desorption device, such as figure 1 As shown, including: nitrogen supply device, heating device, heat exchange device, desorption fan, desorption box and waste gas mixing box;

[0027] The nitrogen supply device communicates with the desorption box through the gas pipeline;

[0028] The desorption box is also communicated with the heat exchange device, the heating device, and the waste gas mixing box through gas pipelines;

[0029] The heat exchange device is also communicated with the heating device and the waste gas mixing box through the gas pipeline;

[0030] The desorption fan communicates with the heat exchanger through the gas pipeline.

[0031] Optionally, the exhaust gas mixing box is provided with an air induction pipe, which is the same as the external air through the air induction pipe, and a one-way valve is arranged on the air induction pipe; a system fan is installed at the rear end of the exhaust gas mixing box, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com