A multi-layer cryogenic test chamber

A test chamber and cryogenic technology, applied in laboratory appliances, heating or cooling equipment, chemical instruments and methods, etc., can solve the problems of slow cooling of the test chamber, loss of low-temperature medium, large loss, etc., and achieve sufficient and accelerated cooling Speed, the effect of preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention is further described;

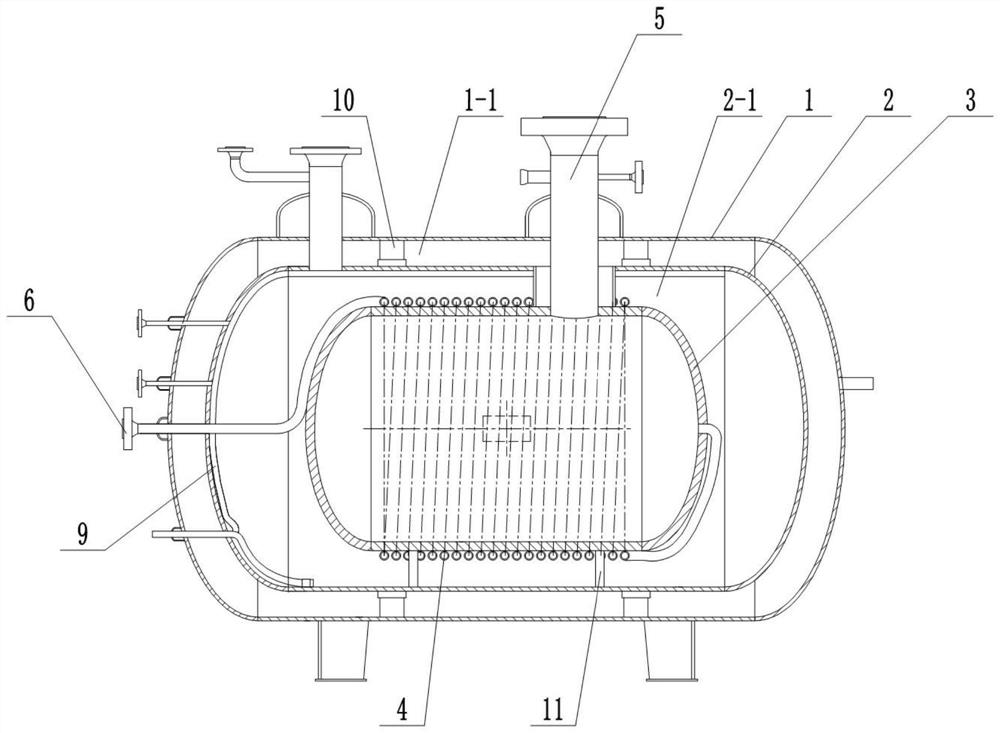

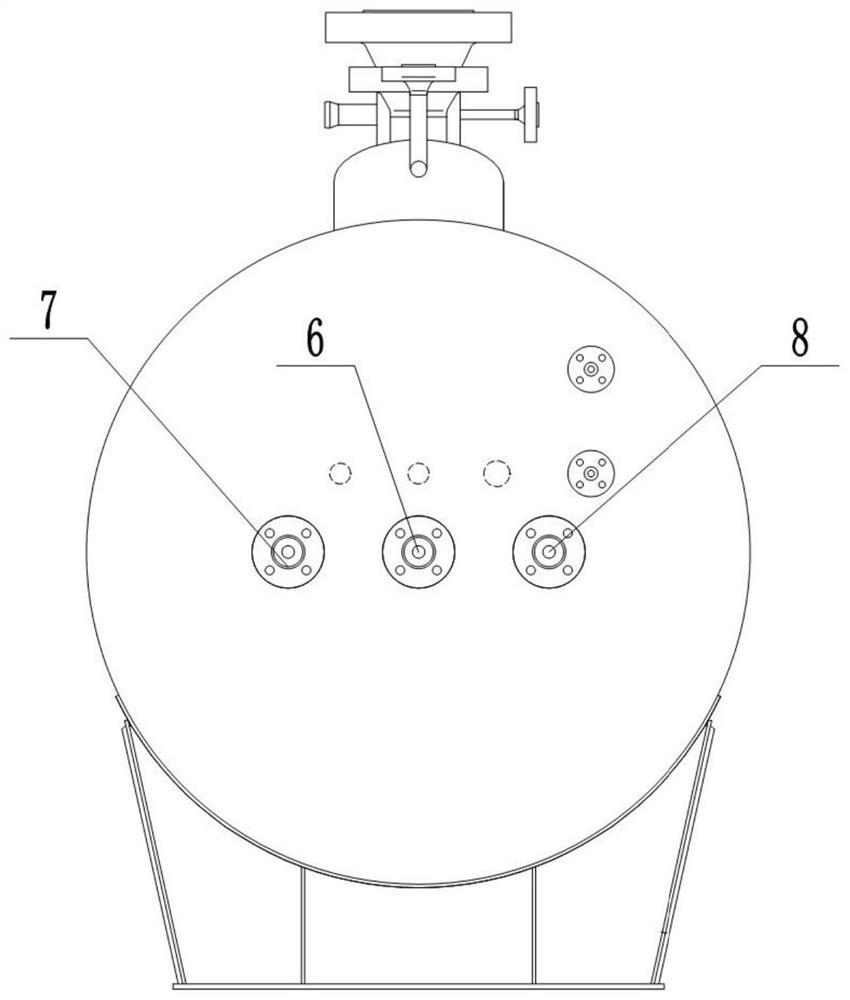

[0013] Please refer to Figure 1-2 , comprising an outer cylinder 1, a test workpiece inlet 5 arranged on the upper surface of the outer cylinder 1, a cylinder-shaped test inner chamber 3, the test workpiece inlet 5 communicates with the test inner chamber 3, and the outer cylinder 1 and the test A middle cylinder 2 is arranged between the inner chambers 3, the outer cylinder 1, the middle cylinder 2 and the test inner chamber 3 are concentrically arranged, and the airtight space between the outer cylinder 1 and the middle cylinder 2 is a vacuum Insulation layer 1-1, the closed space between the middle cylinder body 2 and the test inner chamber 3 is the cryogenic layer 2-1, and the cryogenic layer 2-1 can isolate the test inner chamber 3 in one step, and the low-temperature medium of the general test chamber It is liquid nitrogen, and helium is used as the inert gas. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com