Take-up type new energy charging pile

A charging pile and new energy technology, applied in the field of take-up new energy charging piles, can solve the problems of exposed charging guns, long charging cables, broken wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

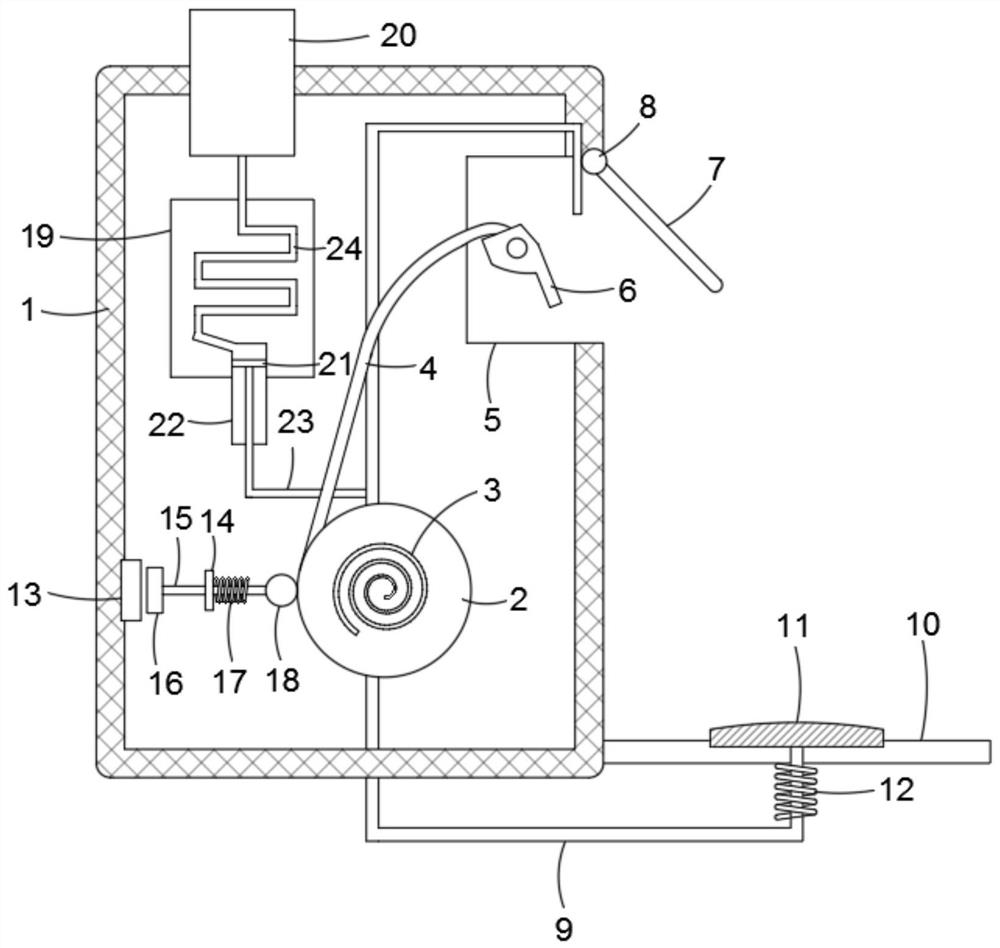

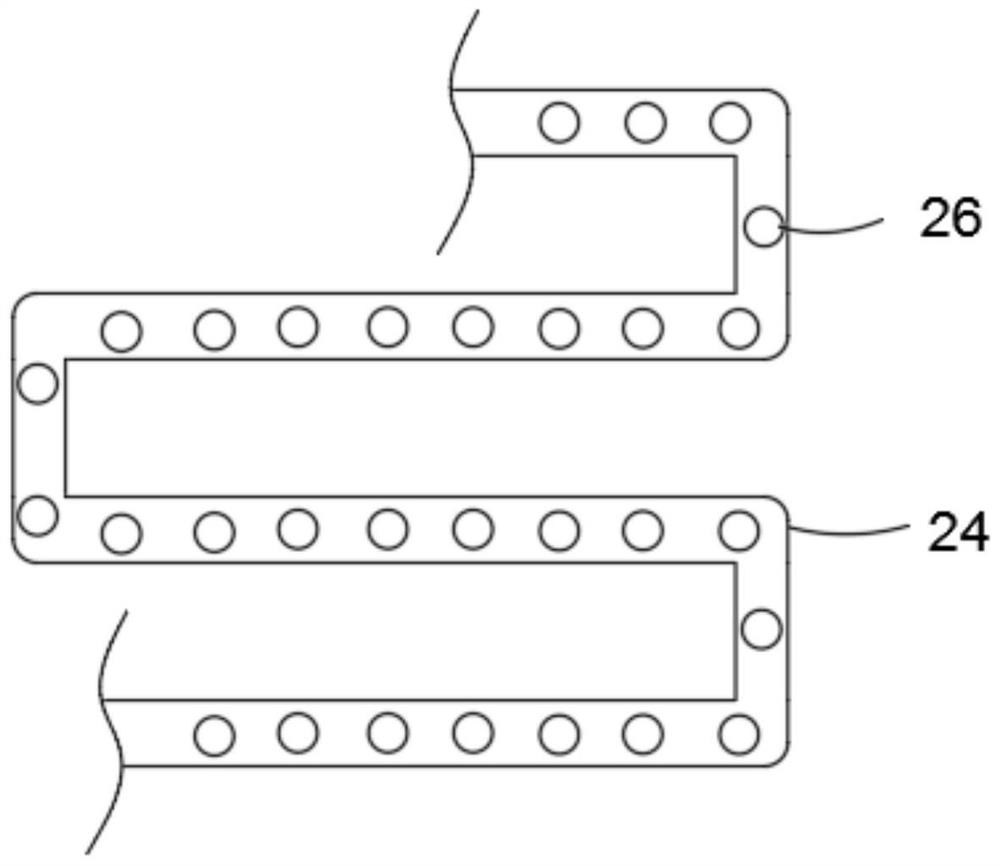

[0026] refer to Figure 1-2 , a take-up type new energy charging pile, including a pile body 1, a take-up reel 2 and a component plate 19 are installed inside the pile body 1, a heat dissipation mechanism connected to the component plate 19 is provided in the pile body 1, and the component plate 19 Including a control module and a power supply module, etc., the heat dissipation mechanism includes a water tank 20 fixedly embedded in the upper side wall of the pile body 1, and the lower side wall of the water tank 20 is connected with a multi-section and continuous cooling pipe 24 in contact with the outer wall of the component plate 19 A plurality of resistance steel balls 26 are evenly fixed on the inner wall of the cooling pipe 24, and the resistance steel balls 26 are set to slow down the flow velocity of water in the cooling pipe 24, so as to ensure that the water can reduce the heat generated on the assembly plate 19 and then flow down after sufficient absorption. The lowe...

Embodiment 2

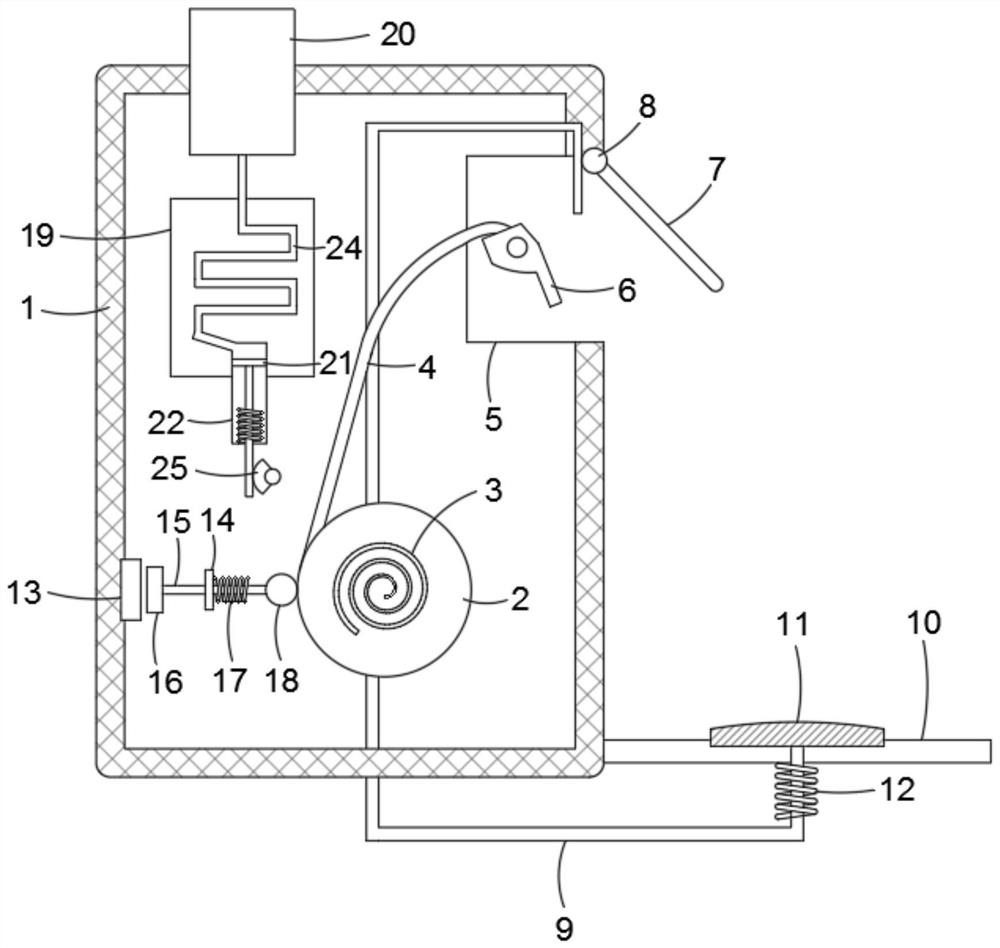

[0030] refer to image 3 , the difference from Example 1 is:

[0031]The heat dissipation mechanism includes a water tank 20 fixedly embedded in the upper side wall of the pile body 1. The lower side wall of the water tank 20 is connected with a multi-section and continuous cooling pipe 24 in contact with the outer wall of the component plate 19. The lower end of the cooling pipe 24 is connected with a suction pipe. Pipe 22, the inner wall of the suction pipe 22 slides with a piston 21, the lower side wall of the piston 21 is fixedly connected with a tooth plate, and a connecting spring is fixedly connected between the outer wall of the tooth plate and the inner bottom wall of the suction pipe 22, and the pile body 1 A motor is fixed inside, and the driving end of the motor is fixedly connected with an incomplete gear 25 that meshes with the tooth plate. The motor is connected to the output line of the pile body 1. When the pile body 1 starts to work, the motor is energized to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com