Protection device for belt conveyor

A technology of belt conveyor and protection device, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of conveyor belt stacking, conveyor equipment damage, flanging and other problems, so as to avoid equipment failure. Damage and injury to personnel, reduced maintenance costs, improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

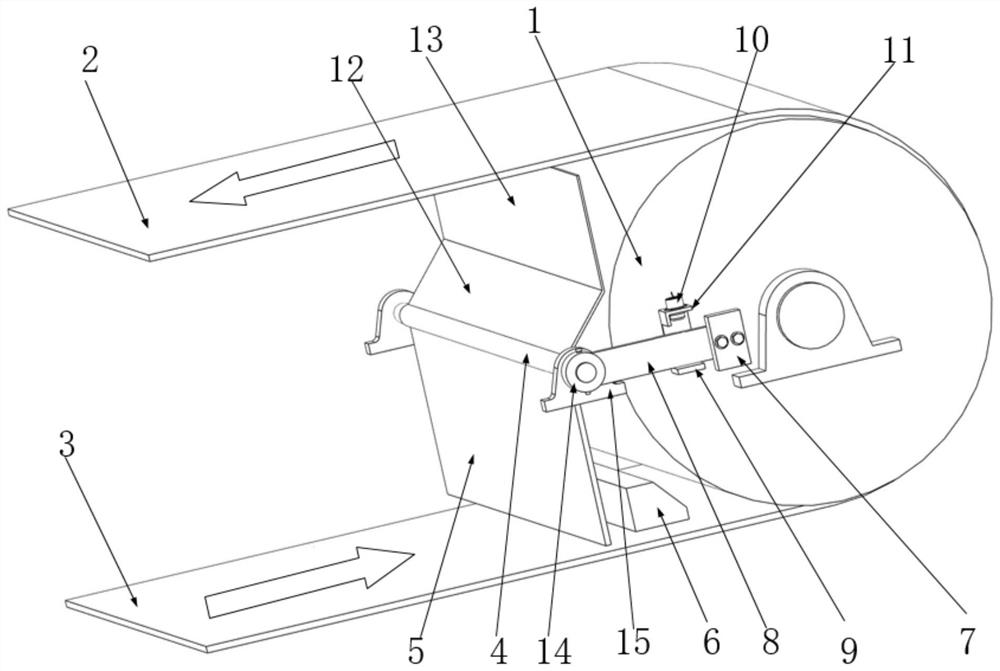

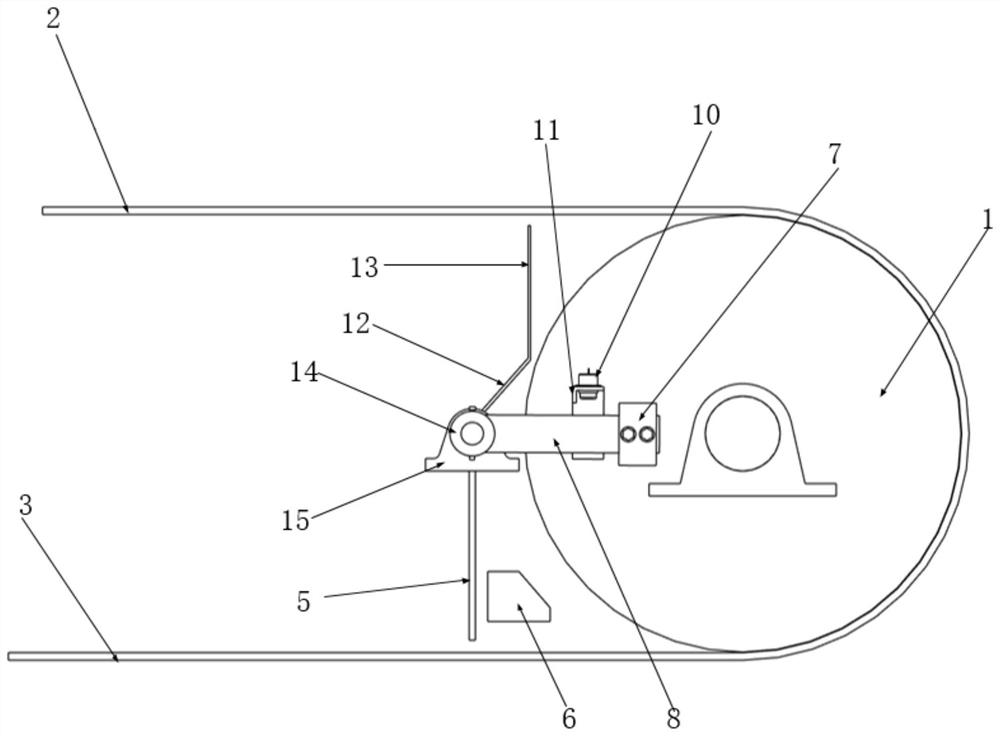

[0041] The belt conveyor includes a frame, a driving mechanism for driving the belt conveyor, a driving drum, a reversing drum 1, and a conveyor belt sleeved on the driving drum and the reversing drum 1, the bottom of the reversing drum 1 and the The conveyor belt moving in the opposite direction of material conveying is the return conveyor belt 3, and the conveyor belt on the top of the diverting drum 1 is the outgoing conveyor belt 2.

[0042] The present invention provides a kind of protection device for belt conveyor for belt conveyor, such as Figure 1~2 As shown, the protective device of the present invention is located on the return conveyor belt 3, and the protective device includes a rotating shaft 4, a foreign matter blocking plate 5 and a rotating trigger mechanism, the rotating shaft 4 is fixedly connected with the frame of the belt conveyor, and the foreign matter blocking plate 5 Vertically arranged, the top of the foreign matter blocking plate 5 is fixedly connect...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the rotation trigger mechanism specifically includes a weight block 7, a weight arm 8, a weight frame 9 and a trigger sensor 10, and one end of the weight arm 8 is fixedly connected to the rotation shaft 4 , the other end is fixedly connected with the heavy hammer block 7, the heavy hammer frame 9, the trigger sensor 10 are fixedly connected with the frame of the belt conveyor, and the bottom of the heavy hammer arm 8 conflicts with the heavy hammer frame 9.

[0050] The weight of the weight block 7 can be adjusted according to the condition of the conveyed material, the actual working conditions on site, and the specific structure of the belt conveyor, so as to improve the detection sensitivity and prevent false triggering.

[0051] In this embodiment, the trigger sensor 10 is a proximity sensor.

[0052] When the protection device of this embodiment is in use, if a foreign matter appears on the return con...

Embodiment 3

[0054] The difference between this embodiment and Embodiment 2 is that in order to prevent the heavy hammer arm 8 from oversteering and to install the trigger sensor 10, the rotating trigger mechanism also includes a sensor bracket 11 for fixing the trigger sensor 10 and limiting the rotation angle of the heavy hammer arm 8. The sensor 10 is disposed on the sensor bracket 11 .

[0055] In this embodiment, the sensor bracket 11 is L-shaped.

[0056] When in use, the heavy hammer arm 8 is in conflict with the sensor bracket 11 after rotating a certain angle around the rotating shaft 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com