Led display tape sticking machine and its working method

A technology of LED display screen and sticking tape, applied in the direction of cleaning method using tools, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as poor efficiency and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

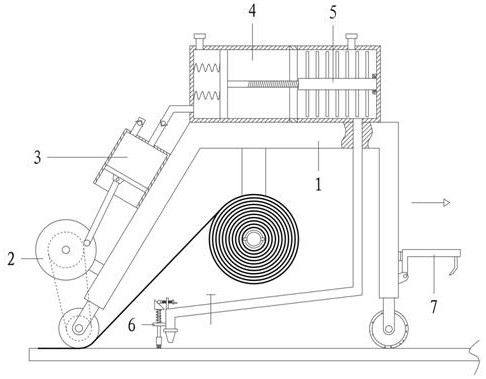

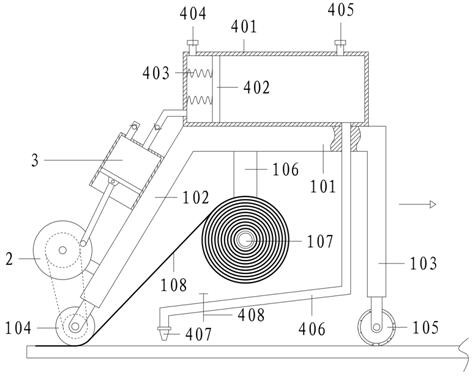

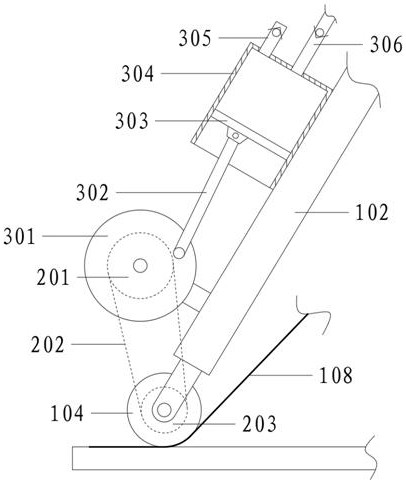

[0061] Referring to the drawings, the tape machine for LED display screen includes a frame assembly 1, a transmission assembly 109, an inflatable assembly 3 and a gluing assembly 4;

[0062] The frame assembly 1 includes a top plate 101, a left leg 102, a right leg 103, a pressing roller 104, a cleaning roller 105, a fixing rod 106 and a mounting shaft 107; the left end of the top plate 101 is connected with a left leg 102, and the right end is connected with a right support Leg 103; the bottom end of the left leg 102 is equipped with a pressing roller 104, and the bottom end of the right leg 103 is equipped with a cleaning roller 105; a fixing rod 106 is connected below the top plate 101, and an installation shaft 107 is connected to the front side of the fixing plate, and the installation shaft 107 is used for Tape 108 for wrapping into a plate;

[0063] The left leg 102 is provided with an inflatable assembly 3 , which cooperates with the pressing roller 104 through a trans...

Embodiment 2

[0065] Referring to the drawings, the tape machine for LED display screen includes a frame assembly 1, a transmission assembly 109, an inflatable assembly 3 and a gluing assembly 4;

[0066] The frame assembly 1 includes a top plate 101, a left leg 102, a right leg 103, a pressing roller 104, a cleaning roller 105, a fixing rod 106 and a mounting shaft 107; the left end of the top plate 101 is connected with a left leg 102, and the right end is connected with a right support Leg 103; the bottom end of the left leg 102 is equipped with a pressing roller 104, and the bottom end of the right leg 103 is equipped with a cleaning roller 105; a fixing rod 106 is connected below the top plate 101, and an installation shaft 107 is connected to the front side of the fixing plate, and the installation shaft 107 is used for Tape 108 for wrapping into a disc;

[0067] The left leg 102 is provided with an inflatable assembly 3 , which cooperates with the pressing roller 104 through a transm...

Embodiment 3

[0082] In the above-mentioned embodiment, the tape reel is directly sleeved on the installation shaft 107, which is easy to fall off during use. Therefore, on the basis of Embodiment 2, a fixing assembly 9 is also provided;

[0083] The fixing assembly 9 includes an installation groove 901, a second-class wedge block 902, a spring 903, a limit rope 904 and a limit ring 905;

[0084] The rear section of the installation shaft 107 is fixedly connected to the limit ring 905; the front section of the installation shaft 107 is symmetrically provided with an installation groove 901, and a second-class wedge-shaped block 902 is slidably connected in the installation groove 901, and the inclined surface of the second-class wedge-shaped block 902 faces the front side; The wedge block 902 and the inner bottom of the installation groove 901 are connected by a spring 903 and a limit rope 904 .

[0085] Specifically, the spring 903 makes the second-class wedge-shaped block 902 always tend ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com