Single crystal diamond substrate structure and splicing processing method thereof

A single crystal diamond and substrate structure technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of differences in grinding accuracy, inability to be closely arranged, cracking of joints, etc., to increase growth Surface, the effect of avoiding growth defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

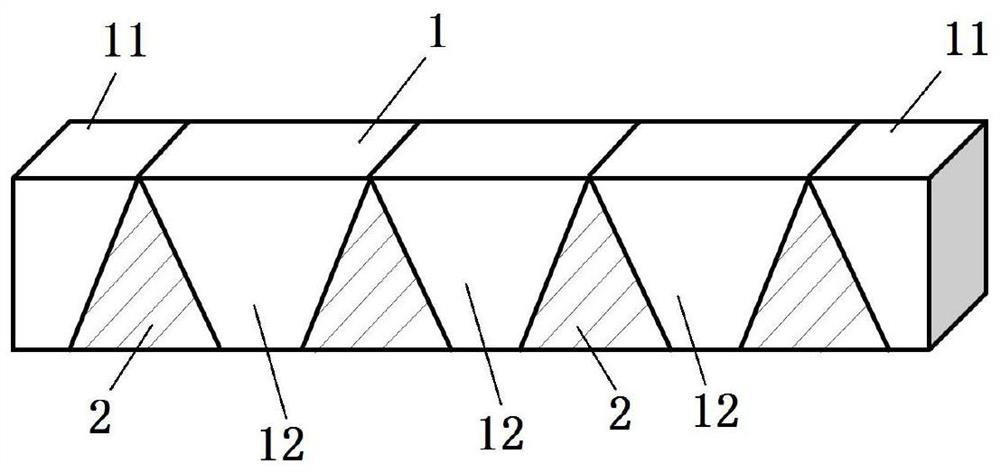

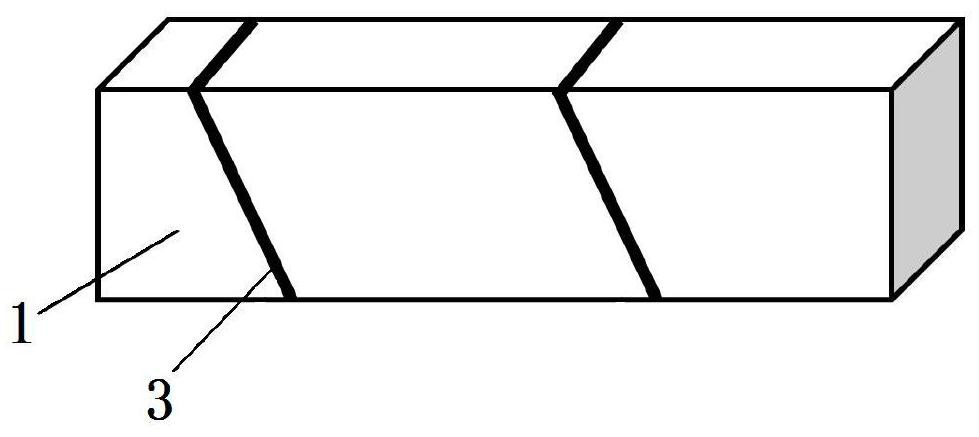

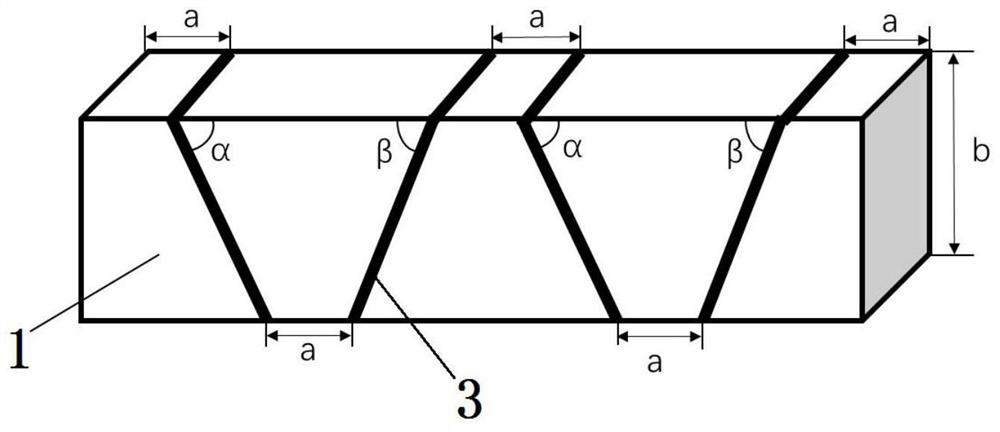

[0031] The invention discloses a splicing processing method of a single crystal diamond substrate structure, comprising the following steps: selecting a single crystal diamond substrate block; wherein, the single crystal diamond substrate block is in the shape of a cuboid, and its crystal orientation is ; The first growth plane of the single crystal diamond substrate block is the initial position, and the single crystal diamond substrate block is cut off; wherein, the section of the single crystal diamond substrate block is a plane, and the section extends from the first growth plane to the opposite side The second growth plane; take the axis parallel to the first growth plane as an axis, turn any block in the cutting block of the adjacent single crystal diamond substrate after cutting, so that the first growth face of a cutting block is adjac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com