Advanced detection, shock isolation and advanced transverse opposite-pull anchor rod system of ultra-small clear distance tunnel

A technology for pulling bolts and advanced detection, applied in bolt installation, directional drilling, construction, etc., can solve the problems of unstable rock interlayer stability and bearing capacity, unfavorable tunnel construction safety, and mutual influence of stress fields. To achieve the effect of simple construction, short construction period and reducing tunnel deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

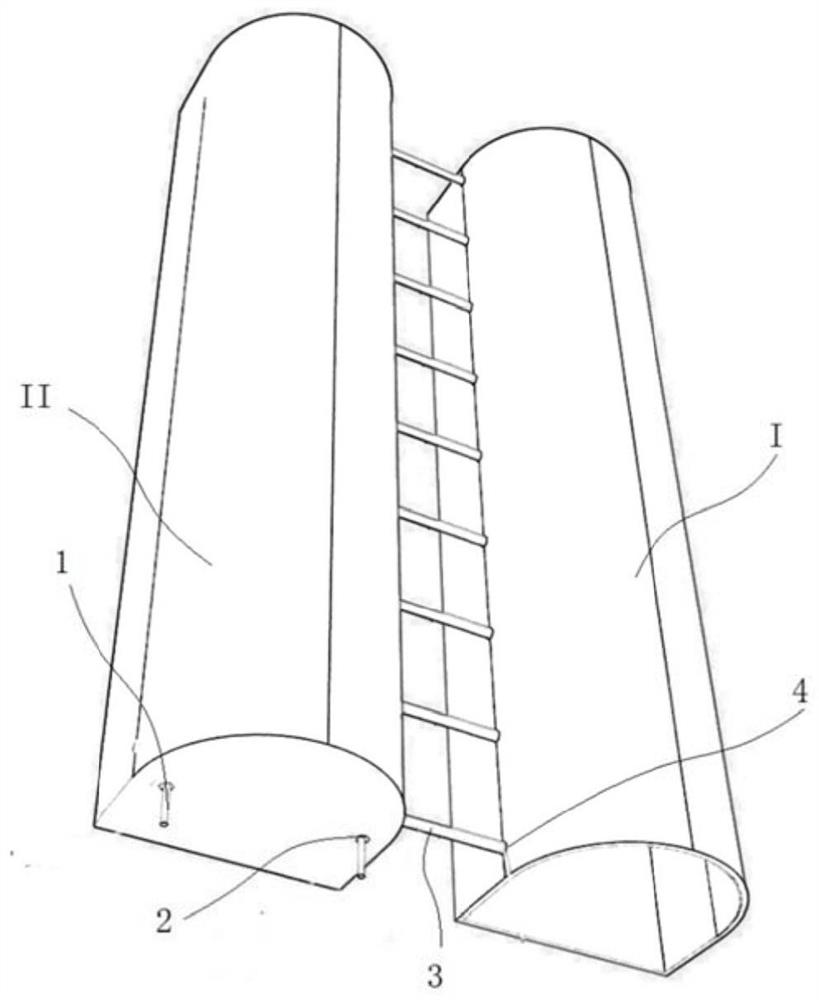

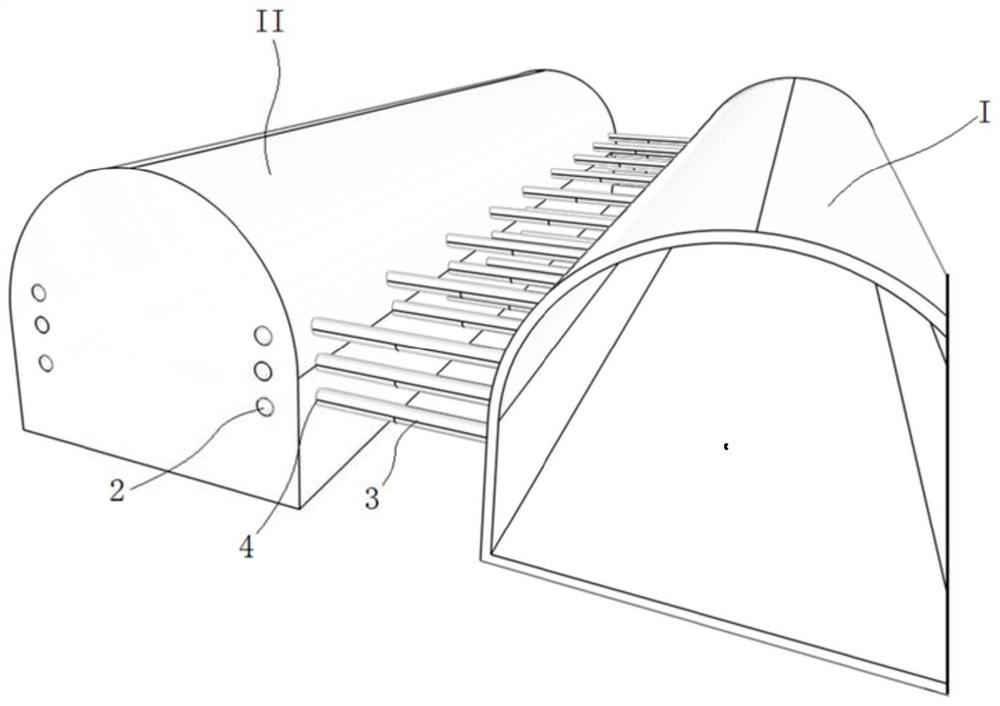

[0034] An advanced detection, seismic isolation and advanced lateral tension bolt system for ultra-small clear distance tunnels, such as Figures 1 to 3 As shown, it is used for tunnel excavation with ultra-small clearance distance, including advanced detection unit and seismic isolation and advanced lateral tension bolt unit;

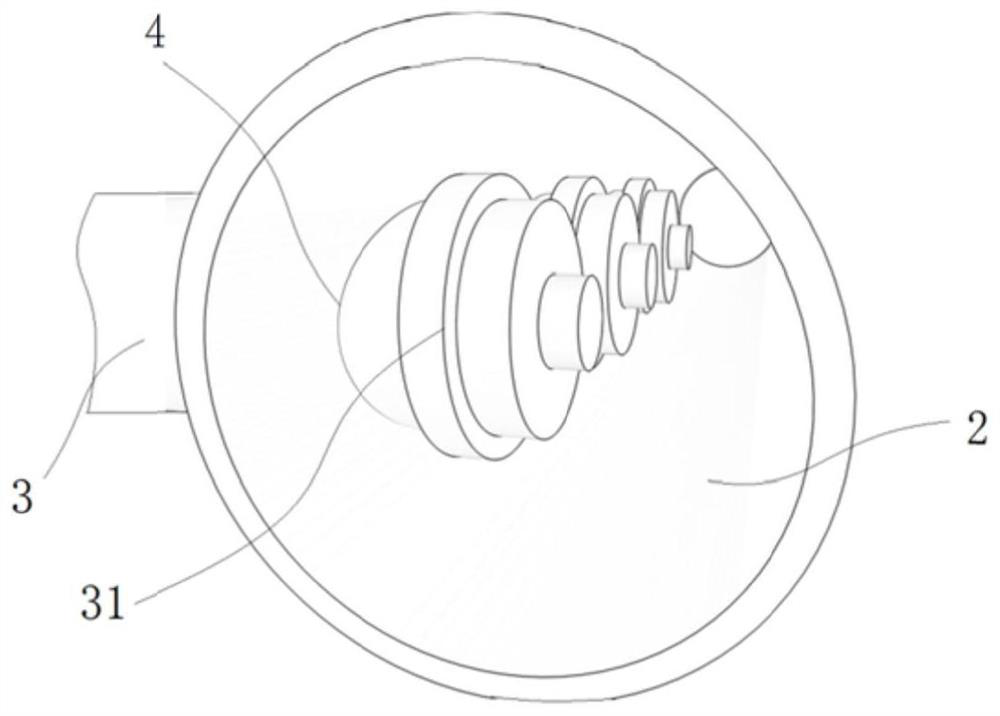

[0035] The advanced detection unit has an advanced horizontal borehole 2 and an in-hole TV probe, wherein: the advanced horizontal borehole 2 is drilled longitudinally along the sidewall profile of the tunnel rearward hole II after excavation of the first tunnel I, and is used for seismic isolation Pressure relief hole, in-hole TV probe 1 is used to identify surrounding rock damage through advanced horizontal drilling 2;

[0036] The seismic isolation and advance lateral pull bolt unit has lateral bolt holes 4 and pull bolts 3, wherein: the lateral bolt holes 4 are drilled from the leading horizontal hole 2 of the tunnel leading hole I to the tunnel tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com