Scroll compressor with enhanced cooling function

A scroll compressor and functional technology, applied in the field of compressors, can solve the problems of increased frequency converter failure rate and unsatisfactory cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

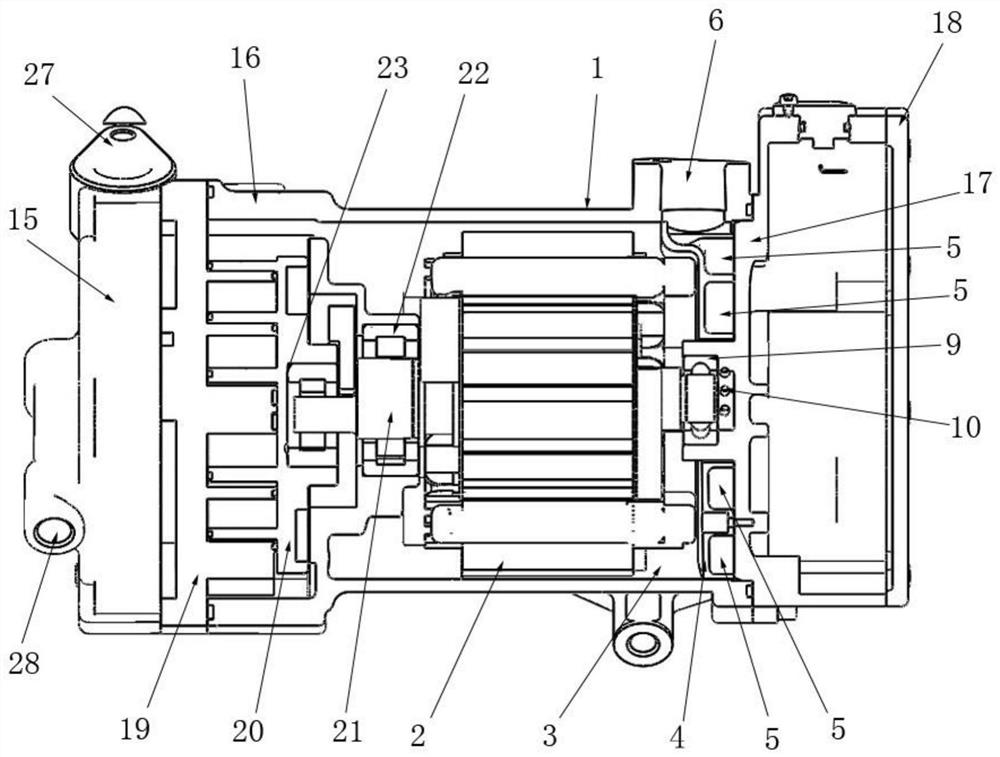

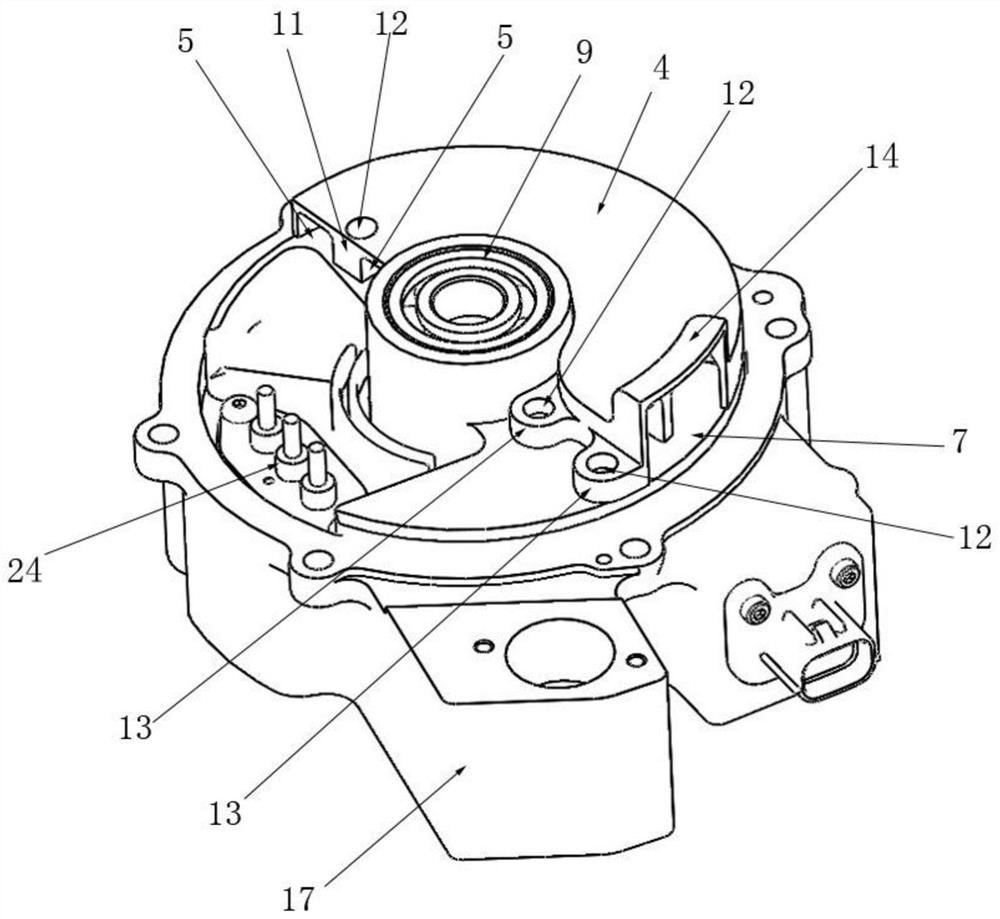

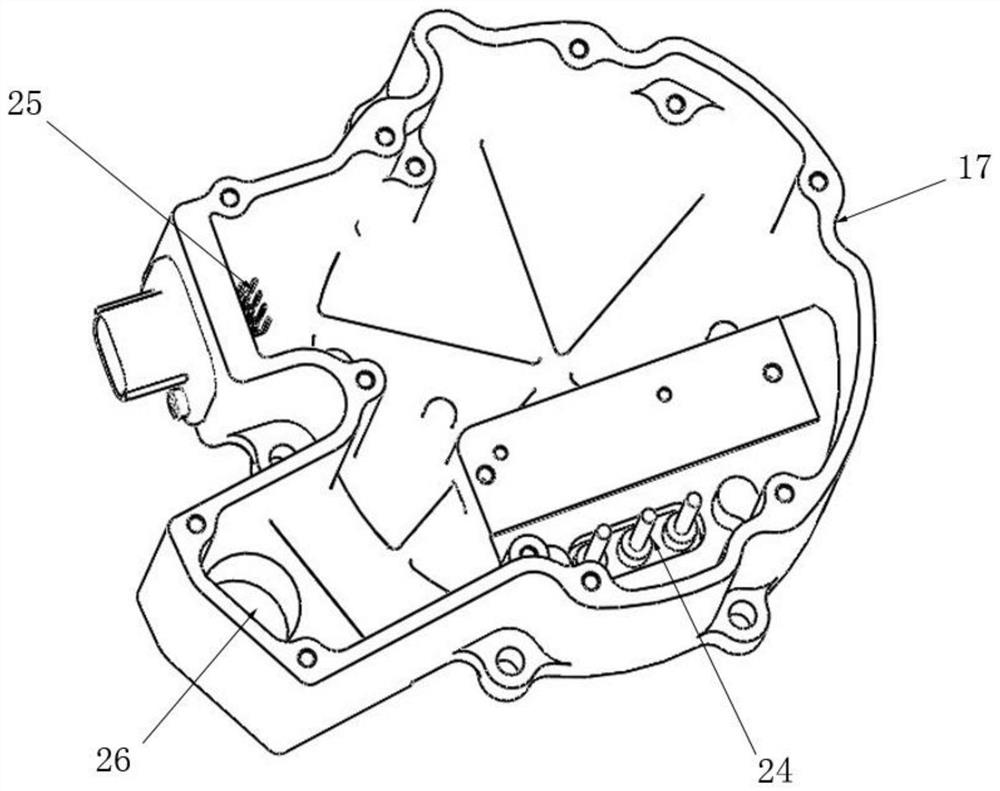

[0038] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 5 As shown, the middle part of one end of the housing 1 is provided with an auxiliary bearing 9, the guide plate 4 is located on the peripheral side of the auxiliary bearing 9, and the inner side of the guide plate 4 is provided with at least one through hole 10 that communicates with the guide channel 5. The hole 10 faces the secondary bearing 9 .

[0039] In a further embodiment of the present invention, the cross-sectional area of the guide outlet 8 is smaller than the cross-sectional area of any one of the guide channels 5 .

[0040] In a further embodiment of the present invention, the guide plate 4 has two guide channels 5 , one guide channel 5 is located inside the guide plate 4 , the other guide channel 5 is located outside the guide plate 4 , and the two guide channels 5 are located on the inside of the guide plate 4 . The inlets of the channels 5 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com