Burner for gas stove

A technology for burners and gas stoves, which is applied in the direction of gas fuel burners, burners, burners, etc. It can solve the problems of incomplete combustion, affecting heat transfer, deformation of the fire cover body, etc., and achieves uniform heating of the bottom of the pot and easy transmission. The effect of fire and air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be further described in detail below with reference to the accompanying drawings embodiments.

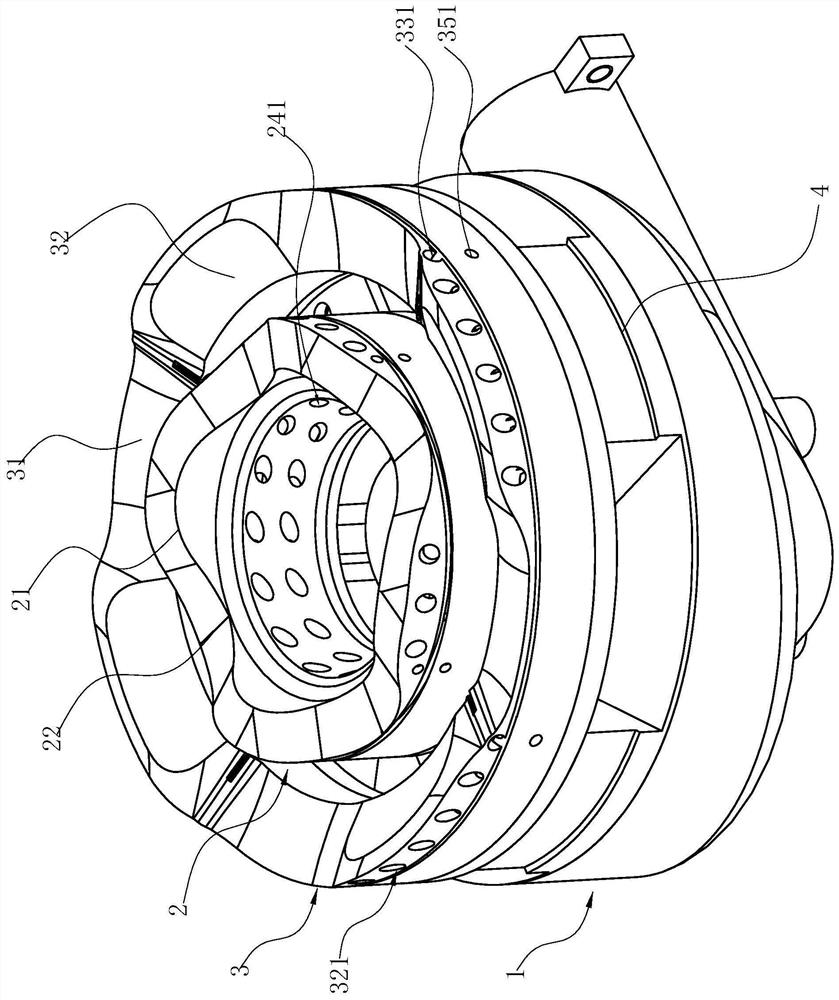

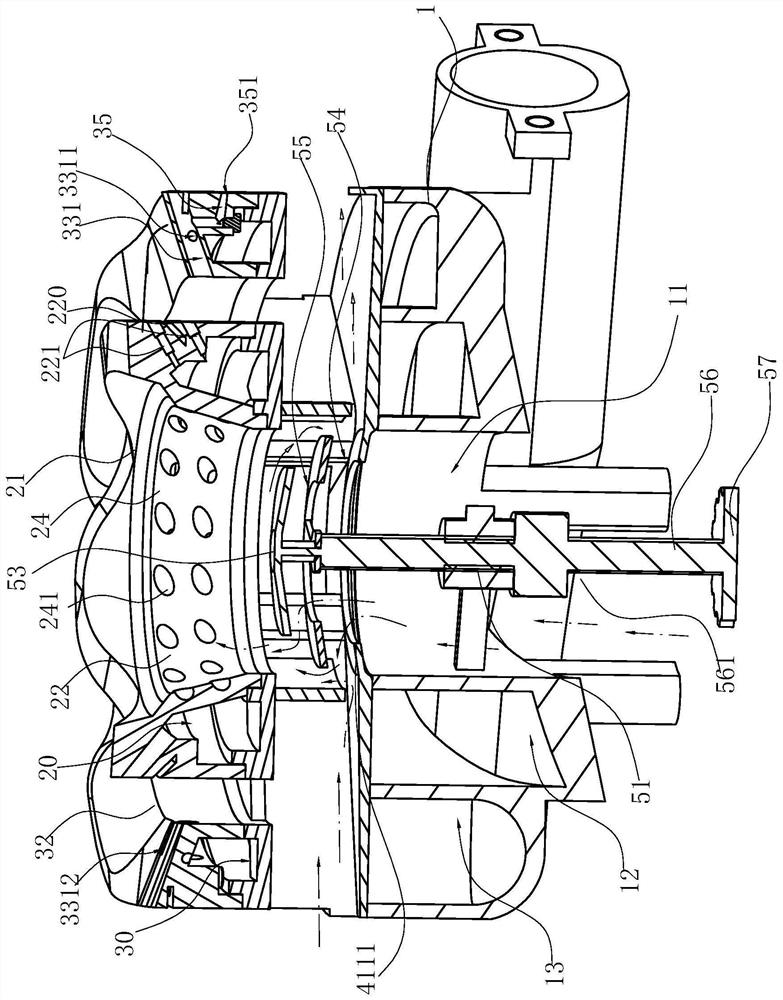

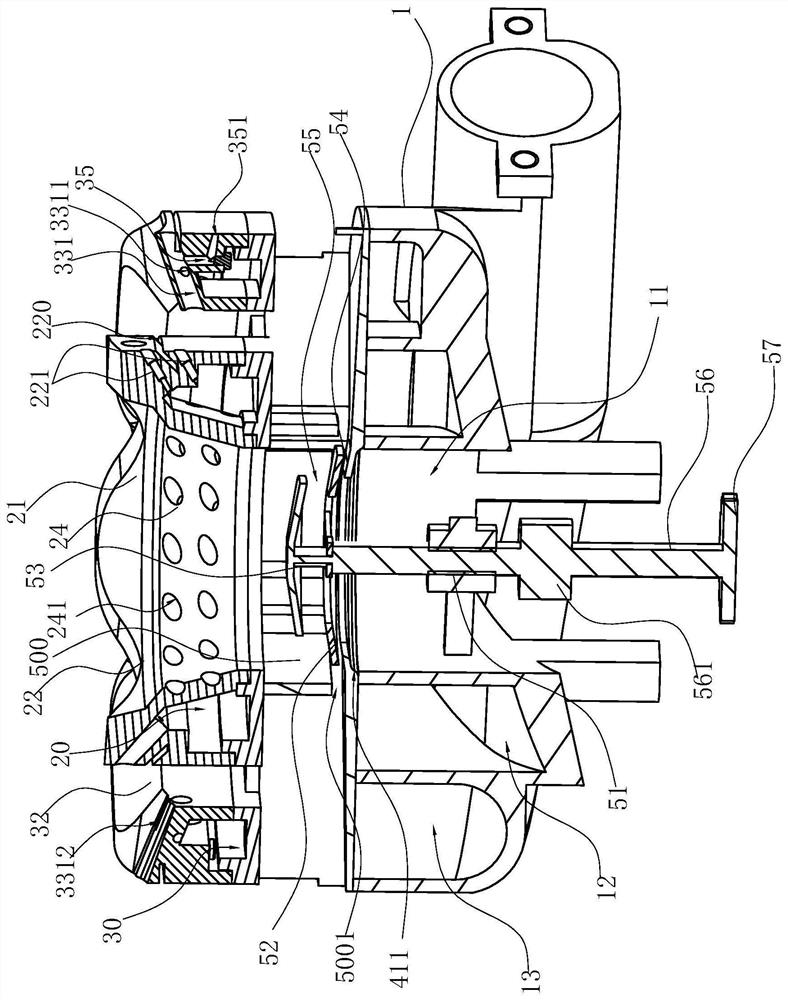

[0035]Such asFigure 1 ~ 9 As shown, it is the best embodiment of the present invention. In this embodiment, the burner for the gas stove includes a base 1, provided above the base 1, has an internal cover 2 having a ignition / aircraft structure, and is also provided above the base 1, provided in the inner The periphery of the fire cover 2, and the ignition / fire structure corresponding to the inner fire cover 2 has an outer fire cover 3 of the fire / ignition structure, wherein the upper surface of the outer fire cover 3 and / or the inner fire cover 2 is partially uneven. The structure and the overall wave-shaped wavy, the ignition / fire structure of the inner fire cover 2 is located in the inner convex portion 21 of its uneven structure, correspondingly, the fire / ignition structure of the outer fire cover 3 is located at its uneven structure. At 31, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com