Smooth blasting method for soft rock roadway

A technology of smooth blasting and roadway, which is applied in blasting, tunneling, earthwork drilling and mining, etc. It can solve the problems of lower labor productivity and construction progress, large consumption of explosives, uneven thickness of smooth blasting layer, etc., and reduce secondary molding The effect of increasing the workload, improving labor productivity, and improving the utilization rate of blastholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

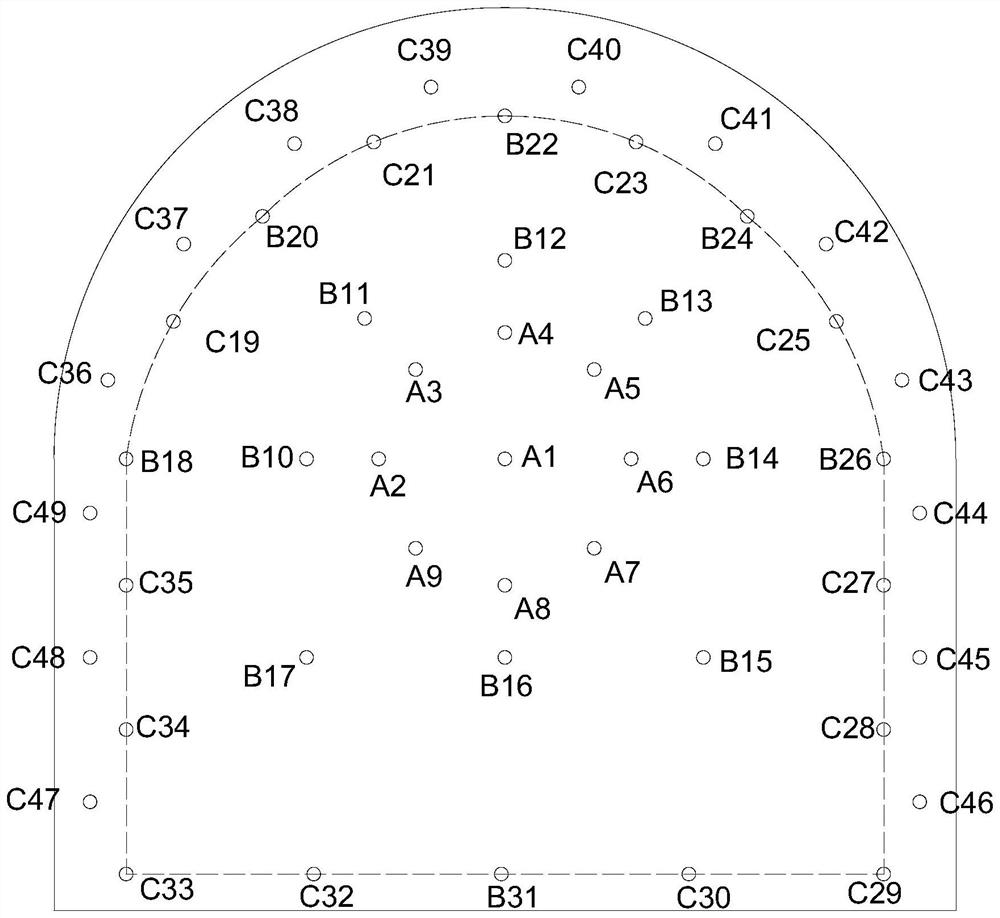

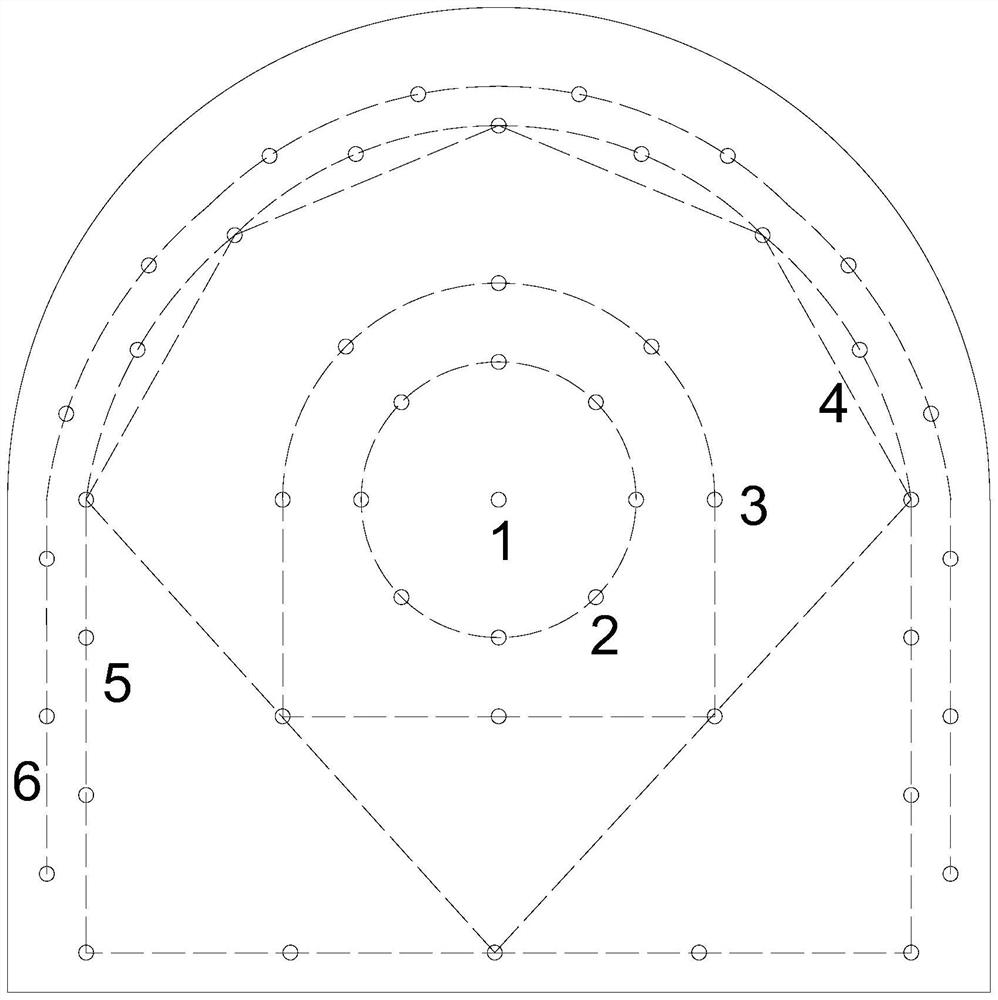

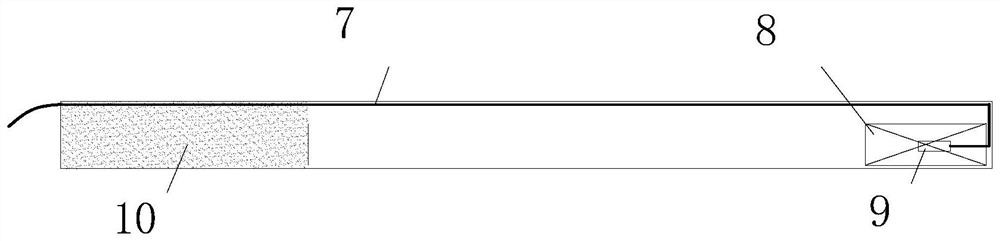

[0027]In order to make the technical problems, technical solutions and advantages to solve the present invention more clearly, and will be described in detail below with reference to the accompanying drawings and specific examples.

[0028]It should be noted that the specification and claims of the present invention and the terms "first", "second", "second" or the like are used to distinguish a similar object without having to describe a particular order or ahead order. It should be understood that the data such as use can be interchanged in place so that the embodiments of the invention described herein can be implemented in the order other than those illustrated or described herein. Moreover, the terms "including" and "having" and any variations are intended to cover non-rowing, such as process, methods, systems, products, or equipment that contain a series of steps or units, including a series of steps or units, not necessarily limited to clearly These steps or units may include oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com