Differential MEMS gas sensor

A gas sensor, differential technology, applied in instruments, scientific instruments, analytical materials, etc., can solve the problem that the measurement accuracy cannot meet the needs of monitoring purposes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

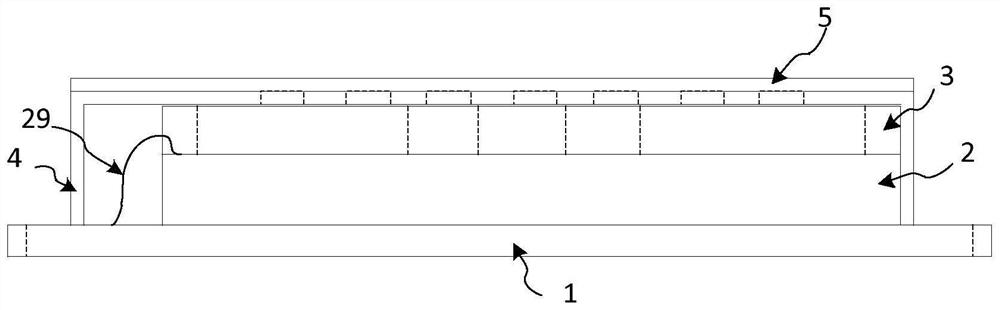

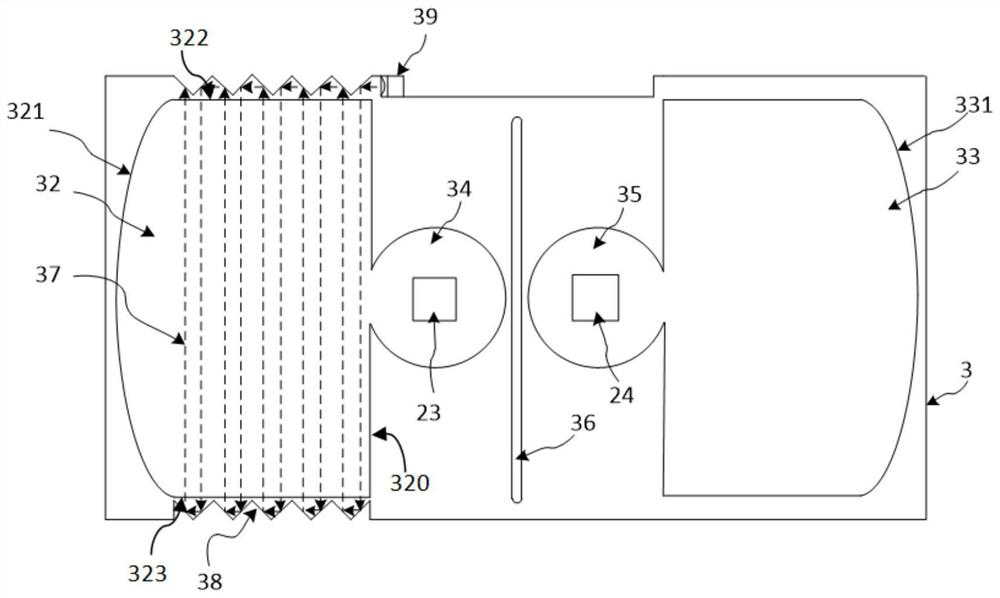

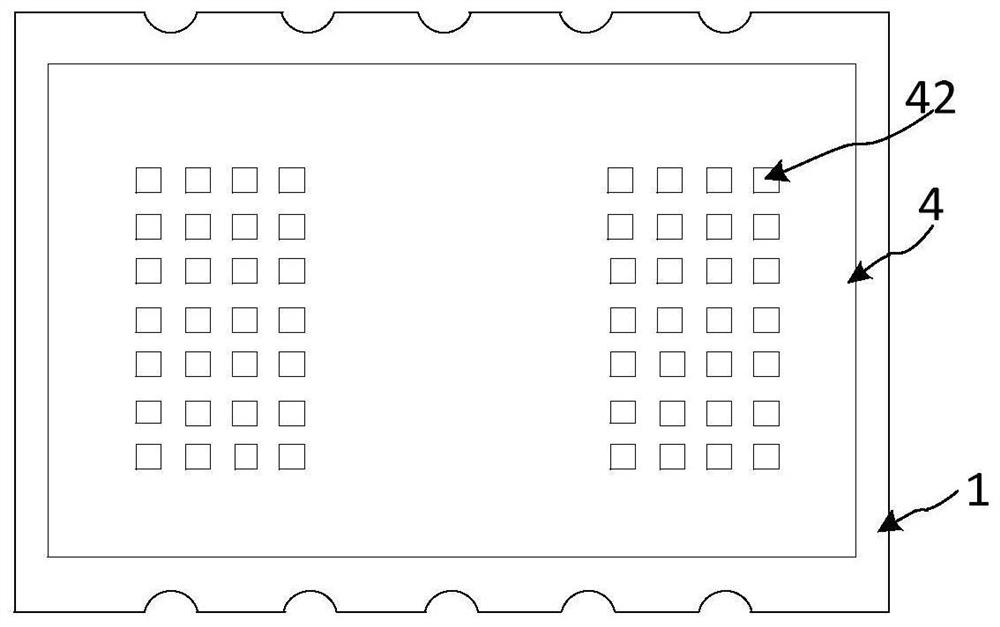

[0021] The present invention provides the specific structural forms of the two groups of chambers that construct the sensor. As shown in the figure, the sensor of the present invention includes a substrate layer 1, a chip layer 2, a cavity wall layer 3, an encapsulating upper shell 4 and a water-proof and breathable chamber. filter membrane 5;

[0022] The substrate layer 1, the chip layer 2 and the cavity wall layer 3 are stacked and fixed sequentially from bottom to top, the bottom surface of the surrounding side walls of the packaging upper shell 4 is sealed and fixed with the substrate layer 1, and the upper cover plate of the packaging upper shell 4 is superimposed on the cavity wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com