Method for evaluating machining performance of hybrid robot under different poses based on spiral hole milling

A technology of helical milling and processing performance, which is applied in the direction of instruments, manipulators, manufacturing tools, etc., can solve the problems of weak rigidity, hole making precision and multiple drilling processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the content, features and effects of the present invention, the technology of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

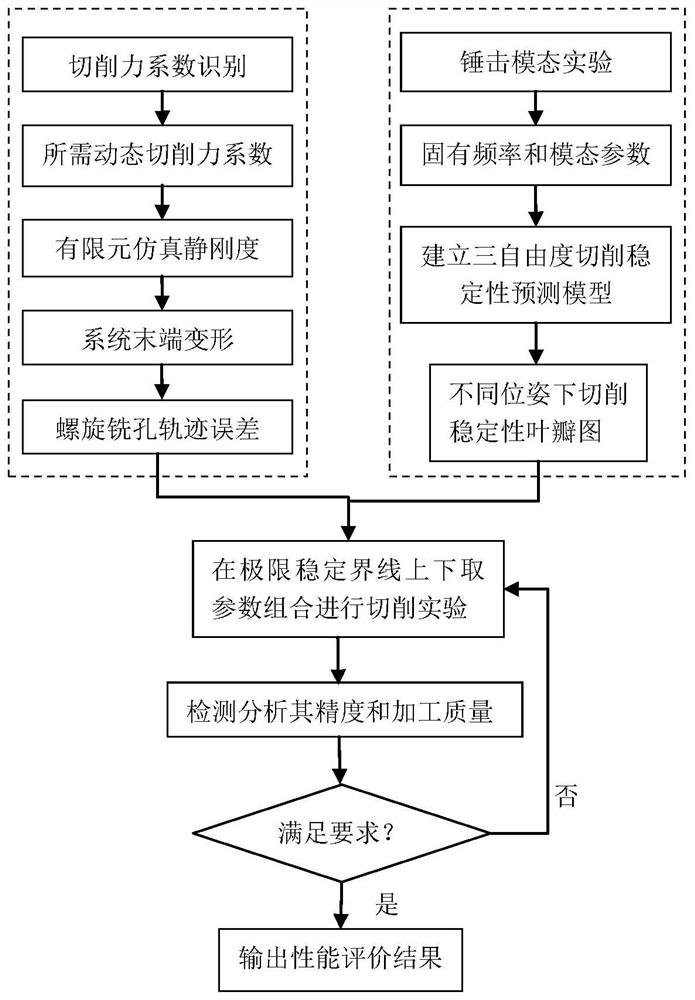

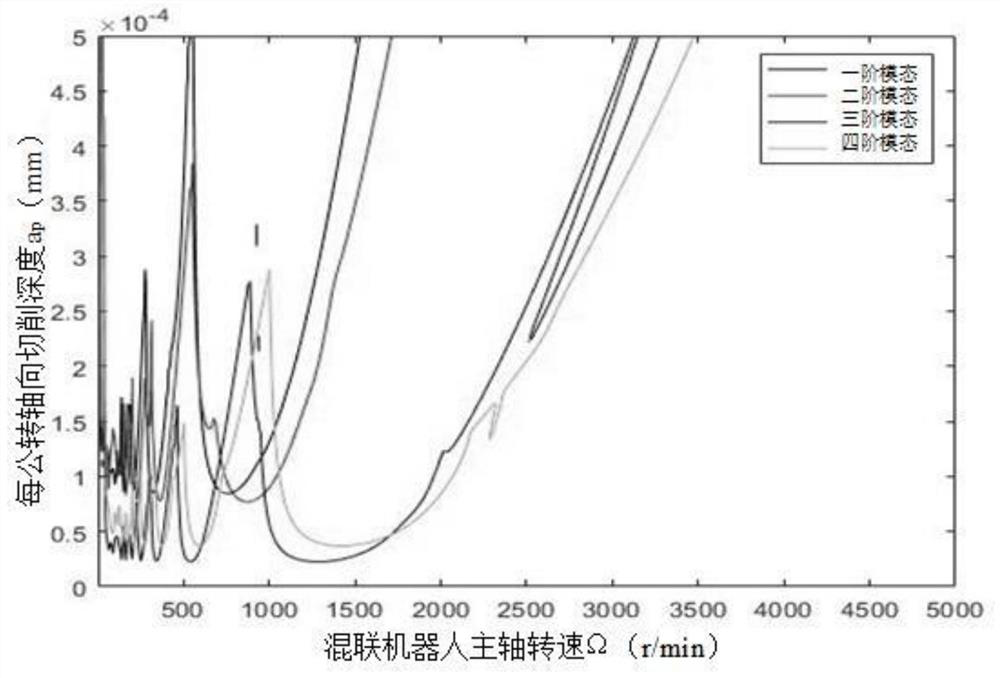

[0036] as attached figure 1 As shown, the processing performance evaluation method of the hybrid robot based on the helical milling hole in different poses of the present invention comprises the following steps:

[0037] Step 1. Obtain the cutting force coefficient, the process is:

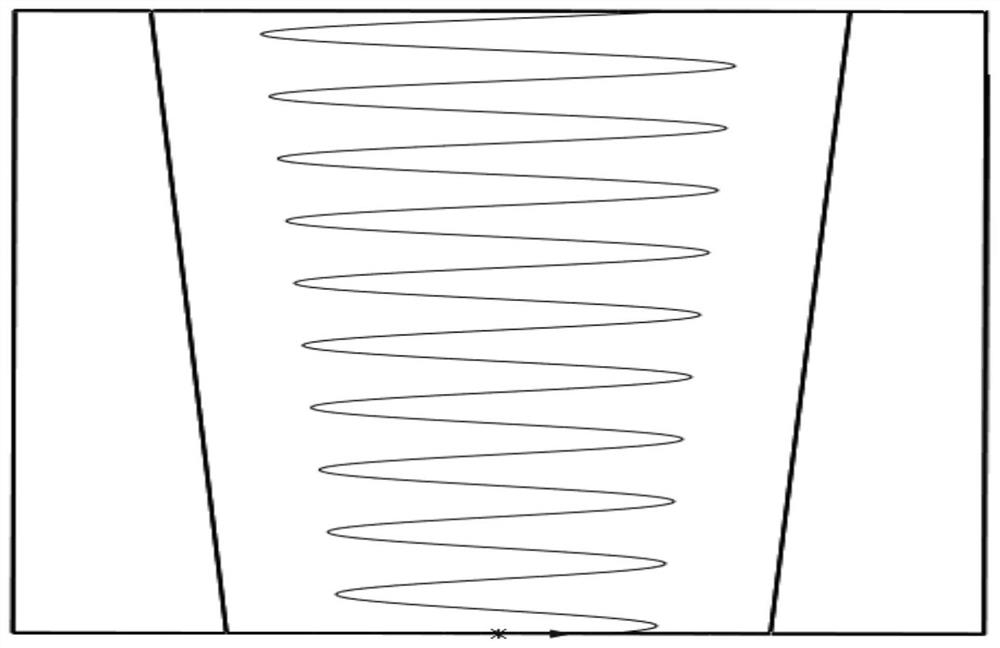

[0038] In the first step, the kinematics of the helical milling hole can be decomposed into rotation along the tool axis, revolution around the centerline of the hole, and axial feed of the tool. During the entire cutting process, both the side edge and the bottom edge of the tool participate in cutting, and the side edge of the tool The dynamic cutting thickness is the main source of dynamic cutting force, and the dynamic cutting force is the cause of robot chatter....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com