Environment-friendly fireproof acoustic board

A sound-absorbing panel and an environmentally friendly technology, which is applied in the field of acoustic decoration materials for stage performances, can solve the problems of complicated production work, weak sound-absorbing panel strength, and no fireproof performance, and achieve the effect of avoiding sound accumulation and good fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

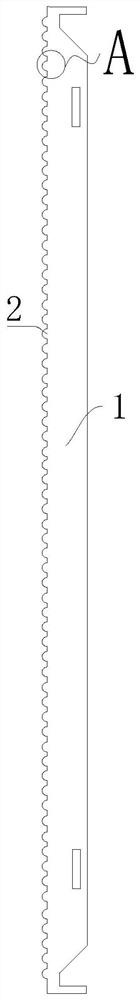

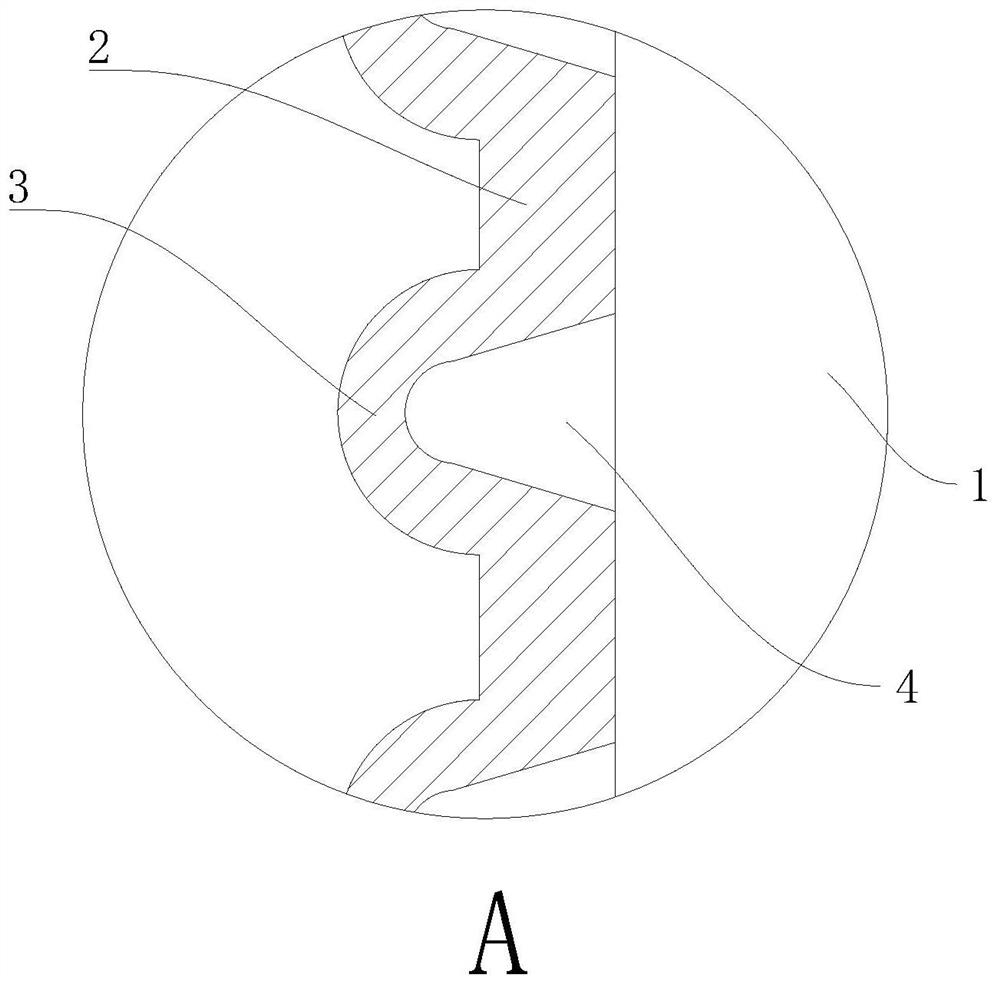

[0020] see Figure 1-2 , the present invention provides an environment-friendly fire-proof sound-absorbing panel, comprising a base plate 1 and a base plate 2, the base plate 1 and the base plate 2 are made of metal materials, the thickness of the base plate 2 is 0.5-1 cm, and the side of the base plate 2 away from the base plate 1 is provided with multiple The arc-shaped bump 3 is provided with a sound-absorbing hole 4 on the other side of the base plate 2 opposite to the arc-shaped bump 3, and the sound-absorbing hole 4 and the arc-shaped bump 3 are arranged on the same axis, and the arc-shaped bump 3 is provided with a hole. Shaped bump 3 has a width of 2-3cm, a height of 0.5-1cm, and rounded corners of 0.2-0.5cm. The sound-absorbing hole 4 is funnel-shaped, with a width of 1-2cm and an angle of 30-50 degrees.

[0021] Preferably, the bottom plate 1 and the base plate 2 are made of aluminum alloy.

[0022] Preferably, the thickness of the substrate 2 is 0.9 cm, the width o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com