Heat dissipation protection shell based on wireless reverse power supply

A technology of reverse power supply and protective shell, which is applied in the direction of electrical components, circuit devices, telephone structures, etc., can solve the problems of heat dissipation as soon as possible, discomfort, safety hazards, etc., and achieve the effect of improving heat dissipation efficiency and reducing volume thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

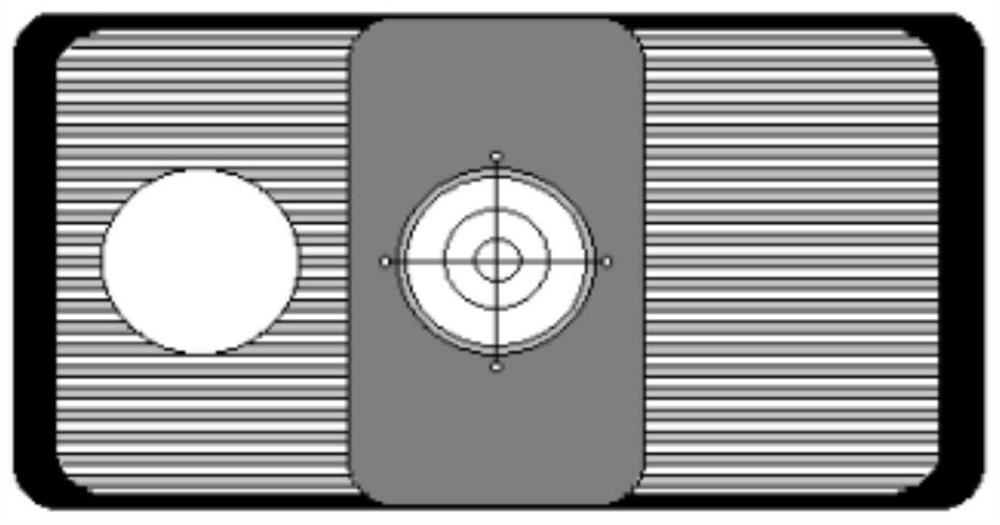

[0040] Such as Figure 9 , the present embodiment selects the heat dissipation structure combining air cooling and semiconductor, and in structural design, water-cooling related components are removed, that is, the water-cooling protruding joint 22 and the water-cooling concave interface are removed from the temperature-conducting metal sheet 2 26 on the temperature-conducting film 31 One 23 and liquid circulation pipeline one 25, the hollowed out area 2 17 and the hollowed out area 3 18 are removed from the heat insulating layer 21, the liquid circulation pump 10, the water-cooling raised joint 11, and the liquid circulation pipeline are removed from the temperature conducting metal sheet 15 Two 39, hollow area one 12, water-cooling protruding joint three 40, so that the current generated by the wireless charging coil 28 is used to supply power to related structures in the air-cooling and semiconductor heat dissipation modes.

[0041] In addition, the terms "first" and "secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com