Heating platform

A heating platform and heating column technology, which is applied in the direction of heating elements, ohmic resistance heating, and the shape of heating elements, etc., can solve the problems that the distribution of electric heating tubes or electric heating wires cannot cover the bottom of the platform, the temperature of the surface of the platform is inconsistent, and the workpiece cannot be heated evenly. Achieve the effects of avoiding failure to bounce, good heating effect and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

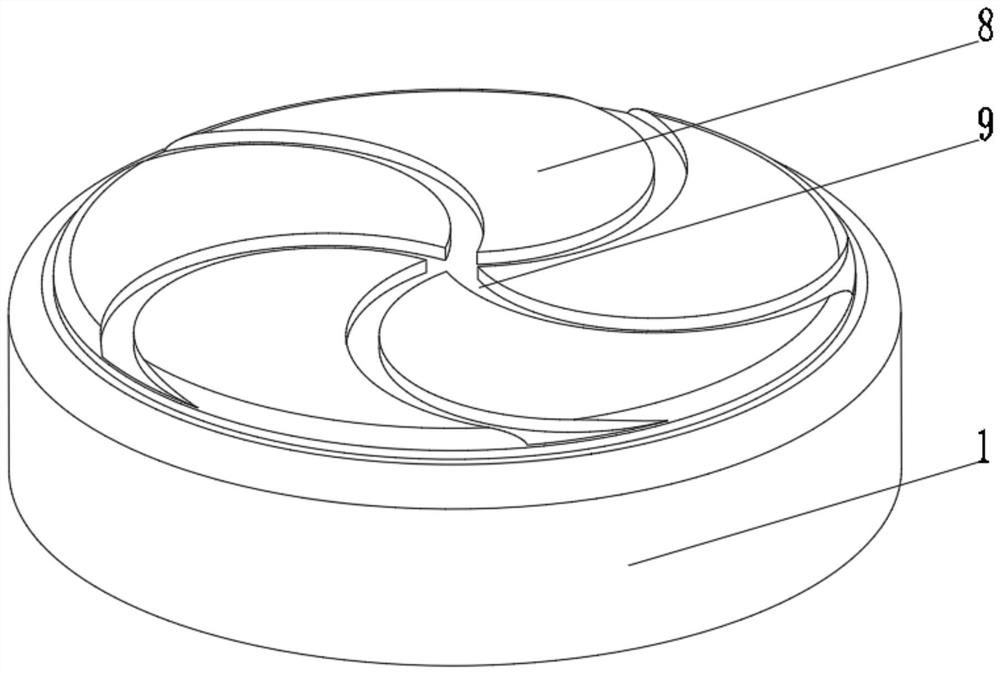

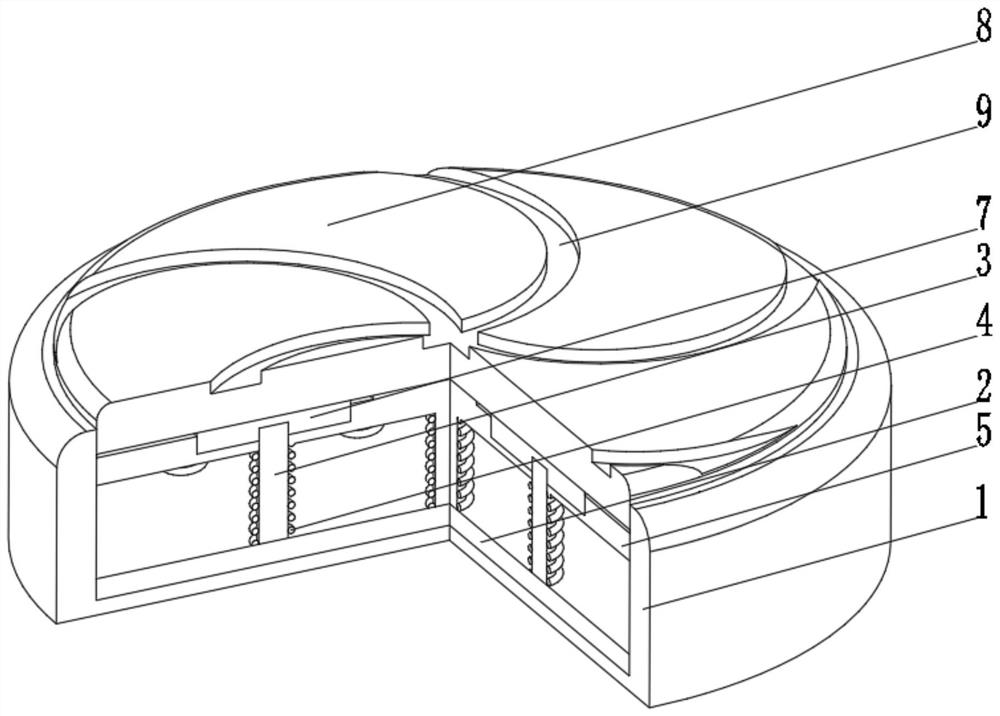

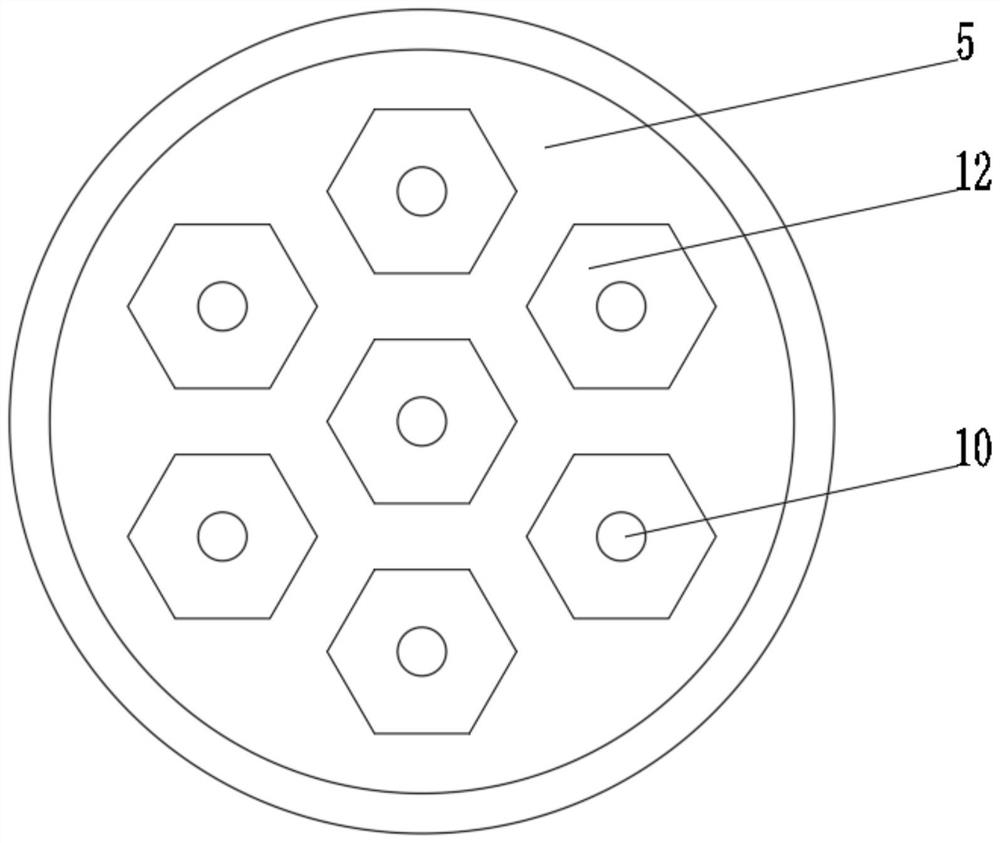

[0031] see Figure 1-5 , the present invention provides a technical solution: a heating platform, including a fixed shell 1, a heating base 2 is fixedly connected to the bottom of the inner wall of the fixed shell 1, a heating column 3 is fixedly connected to the top of the heating base 2, and an electric heating wire is wound on the outside of the heating column 3 4. The part of the inner wall of the fixed shell 1 above the heating column 3 is fixedly connected with the heating plate 5, and the top of the heating plate 5 is provided with a placement groove 12, and both sides of the inner wall of the placement groove 12 are provided with supporting devices 6, and the inner wall of the placement groove 12 is slidingly connected with Graphene heat conduction plate 7, fixed shell 1 inner wall is positioned at the part of heating plate 5 top slidingly connected with graphene heating plate 8, and graphene heating plate 8 top is provided with arc-shaped air guiding groove 9, and plac...

Embodiment 2

[0034] see Figure 1-6 On the basis of Embodiment 1, the present invention provides a technical solution: the support block 63 includes a support block body 631, a rolling groove 632 is opened on one side of the support block body 631, the inner wall of the rolling groove 632 is rotatably connected with a roller 633, and the outer side of the roller 633 A heat insulating pad 634 is fixedly connected, and the side of the support block body 631 is provided with an arc shaped hole 635, and one side of the inner wall of the arc shaped hole 635 is provided with a chute 636, and the inner wall of the chute 636 is slidably connected with an arc slider 637. The top of the slider 637 is fixedly connected with a support column 638, and the end of the support column 638 away from the arc-shaped slider 637 extends to the outside of the chute 636 and is slidably connected with the inner wall of the arc-shaped shaped hole 635. When the graphene heat conducting plate 7 is pressed against the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com