In-tower liquid distribution device for small rectifying tower

A technology of liquid distribution device and rectification tower, which is applied in the direction of fractionation, etc., and can solve the problems of large height space, easy welding bumps and splashes, and large shielding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

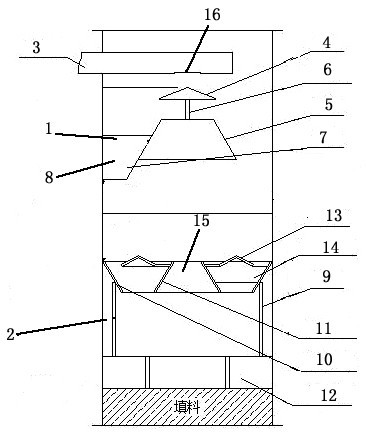

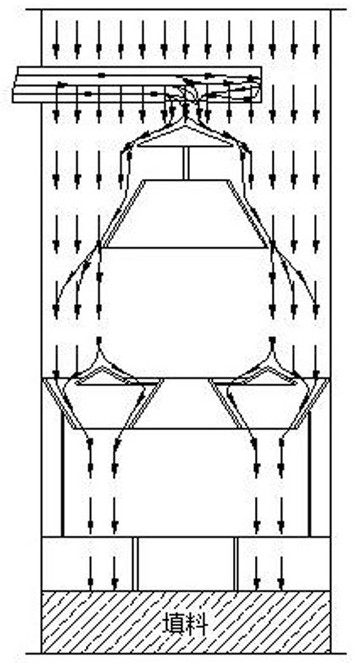

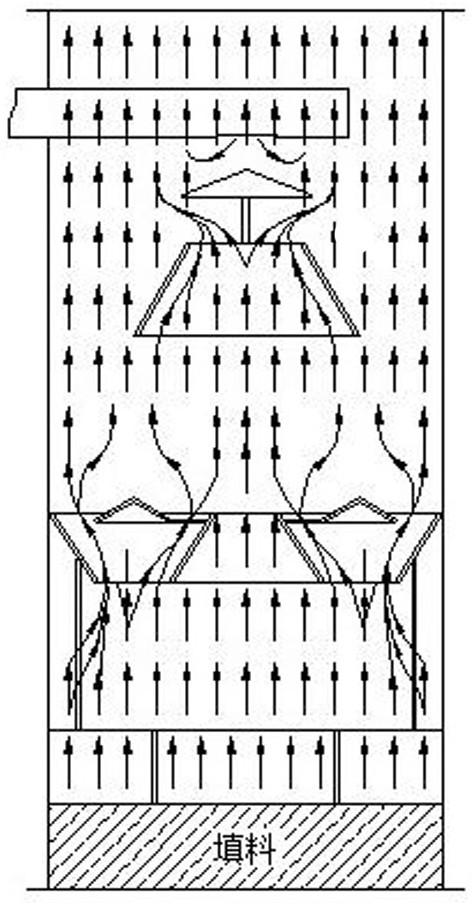

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, a liquid distribution device in a small-scale rectification tower is used, and the distribution device is composed of an upper distributor 1 and a lower distributor 2, wherein the upper distributor 1 is arranged below the feed pipe 3, and consists of a hammer-shaped The cap 4 and the cone 5 are composed of the cap 4 and the cone 5 through the connecting block 6. The cone 5 is fixed in the middle of the tower through the support block 7 at the bottom. The support block 7 is connected by the left and right sides The support bar 8 is welded on the inner wall of the tower, the lower distributor 3 is arranged above the packing fixing part 12 at the bottom of the tower, and a support block 9 is welded above the packing fixing part 12, and the support block 9 is arranged obliquely There is an outer distribution cone 10, the inside of which is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com