Cooling device and cooling method for maltol sublimation section

A technology of a cooling device and a cooling method, which is applied in sublimation, separation methods, chemical instruments and methods, etc., can solve the problems of waste of manpower and material resources, material pollution, waste, etc., and achieve production cost saving, production yield improvement, and high speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

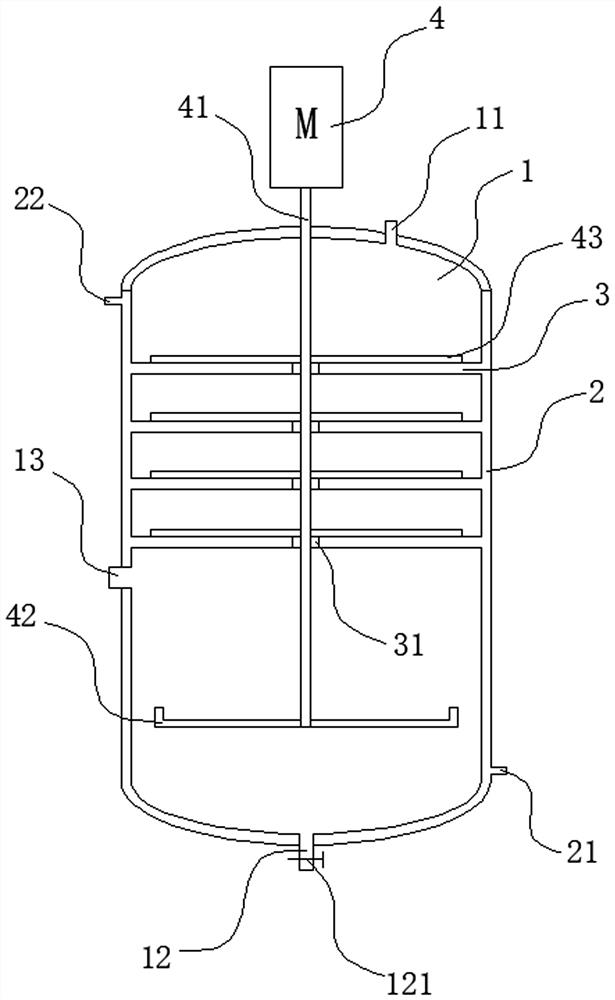

[0018] see figure 1 , the cooling device of the maltol sublimation section, including a reactor 1 with an inner wall enamel, the reactor 1 is a vertically arranged cylindrical shape, the side wall and the bottom wall of the reactor 1 are provided with a jacket 2, and the position of the jacket 2 is The upper part corresponds to the lower part of the reaction kettle 1 with a condensed water inlet 21, the position of the jacket 2 corresponds to the upper part of the reaction kettle 1 with a condensed water outlet 22, the top wall of the reaction kettle 1 is provided with a gas phase port 11 through the top wall, and the bottom wall of the reaction kettle 1 There is a discharge port 12 that runs through the bottom wall, and a discharge butterfly valve 121 is provided on the discharge port 12. The surface of the discharge butterfly valve 121 is covered with polytetrafluoroethylene. The sublimation gas phase inlet 13, the upper part of the reaction kettle 1 is provided with four ci...

Embodiment 2

[0020] The cooling method of the cooling device of maltol sublimation workshop section, comprises the following steps:

[0021] (1) Through the condensed water inlet and condensed water outlet, feed -10°C cooling water into the inner cavity of the jacket and throttle plate, start the motor for stirring, and connect a vacuum pump to the gas phase port to evacuate the reactor to ensure that the reactor Internal vacuum is -0.08MPa;

[0022] (2) The sublimation kettle starts the sublimation operation, and the sublimated gas phase is directly introduced into the reactor through the gas phase inlet for 4 hours;

[0023] (3) The sublimated gas phase enters the reactor to desublimate into a solid material, and the solid material bonded to the upper side of the throttle plate is scraped off by the scraper and falls into the bottom of the reactor from the second through hole;

[0024] (4) Finally, open the butterfly valve at the discharge port to release the solid material into the nex...

Embodiment 3

[0026] The cooling method of the cooling device of maltol sublimation workshop section, comprises the following steps:

[0027] (1) Pass cooling water at -12.5°C into the inner cavity of the jacket and throttle plate through the condensed water inlet and condensed water outlet, and start the motor to stir, and at the same time connect a vacuum pump to the gas phase port to evacuate the reactor to ensure that the reactor Internal vacuum is -0.09MPa;

[0028] (2) The sublimation kettle starts the sublimation operation, and the sublimated gas phase is directly introduced into the reactor through the gas phase inlet for 4 hours;

[0029] (3) The sublimated gas phase enters the reactor to desublimate into a solid material, and the solid material bonded to the upper side of the throttle plate is scraped off by the scraper and falls into the bottom of the reactor from the second through hole;

[0030] (4) Finally, open the butterfly valve at the discharge port to release the solid m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com