Graphite product electrode dipping device

A technology for impregnating devices and graphite products, which is applied in the direction of devices and coatings for coating liquid on the surface, which can solve problems such as inconsistent thermal expansion of graphite materials, increase of impregnation costs by ultrasonic generators, and hazards to the performance of graphite materials. Impregnation efficiency, low cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

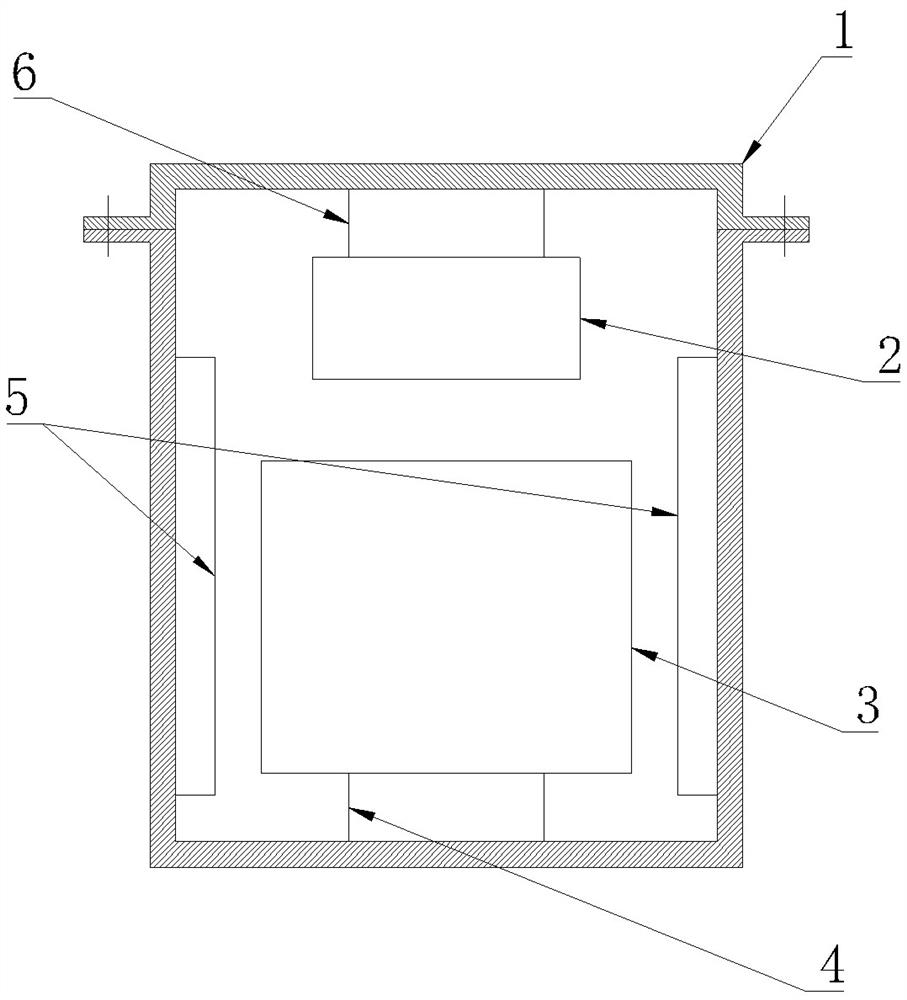

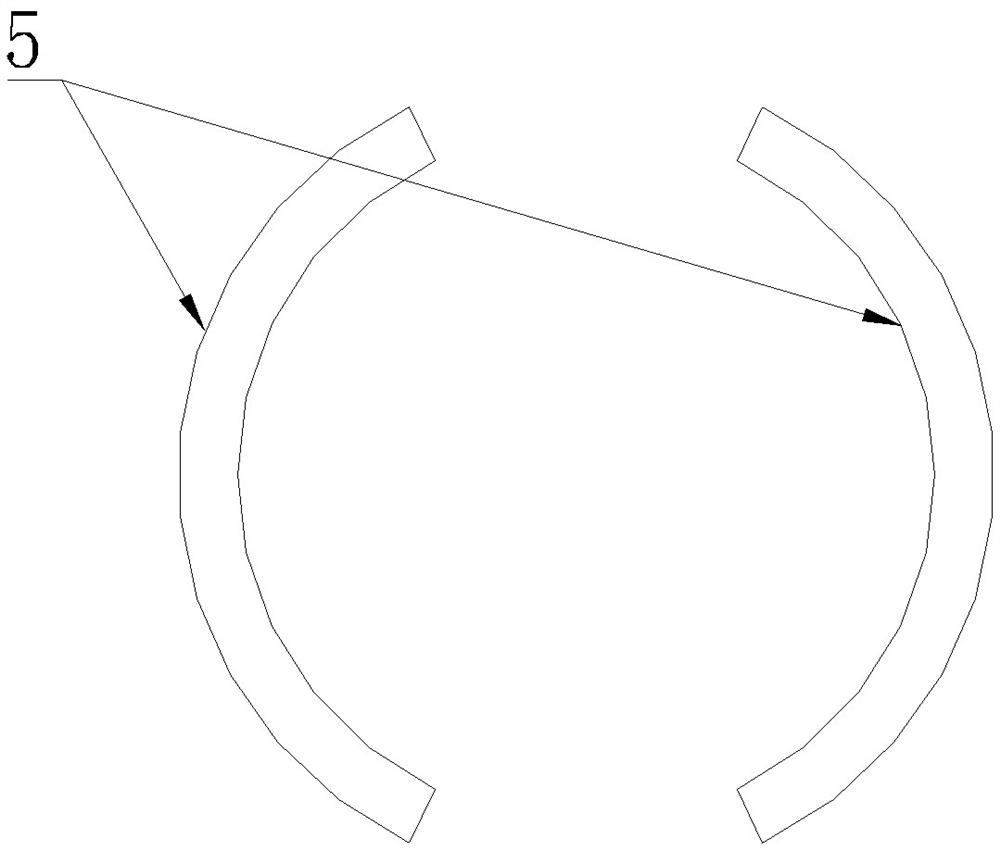

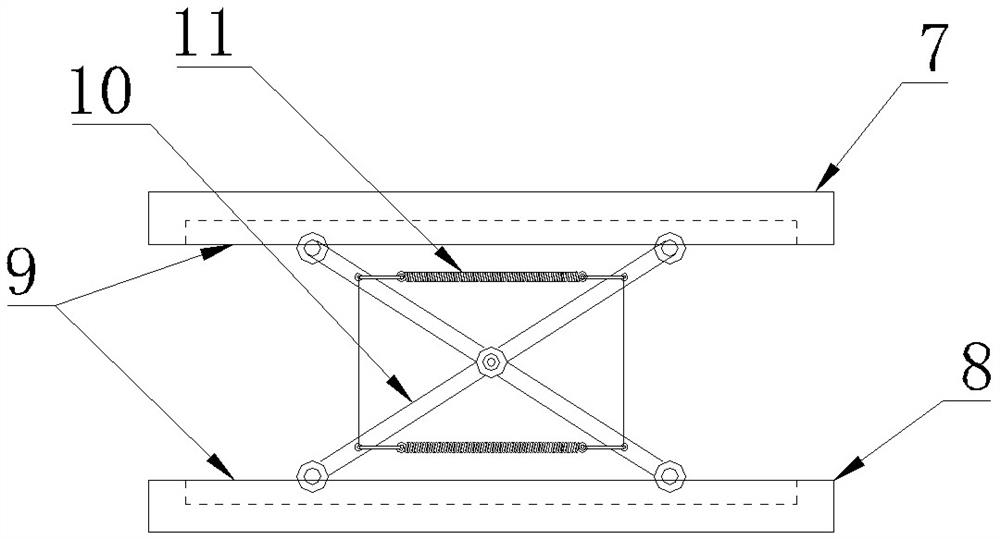

[0019] like Figure 1-4 The electrode impregnation device for graphite products shown includes a cover 1 and an impregnation chamber, a second telescopic module 6 is provided under the cover 1, and an electrode cap is provided between the second telescopic module 6 and the graphite block 3 2. The side wall of the impregnation chamber is provided with high-frequency oscillators 5, and the high-frequency oscillators 5 are arranged in pairs in arc-shaped buckles, and the bottom of the impregnation chamber is provided with a first telescopic module 4, The first telescopic module 4 and the second telescopic module 6 include an upper support plate 7, a lower support plate 8, a cross 10, and a tension spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com