Light-cured resin and preparation method thereof

A technology of light-curing resin and light-curing agent, which is applied in the field of light-curing resin and its preparation, and can solve the problems of affecting the quality of light-curing 3D printing, large yellowing, and poor transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

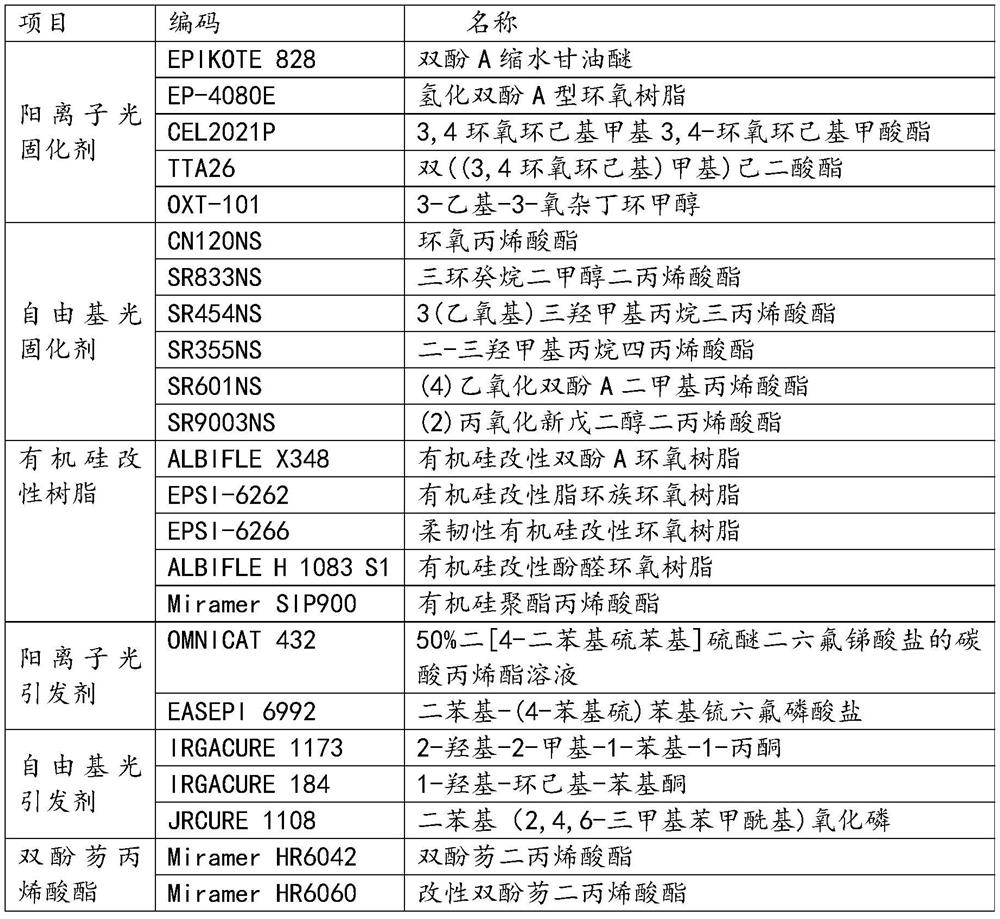

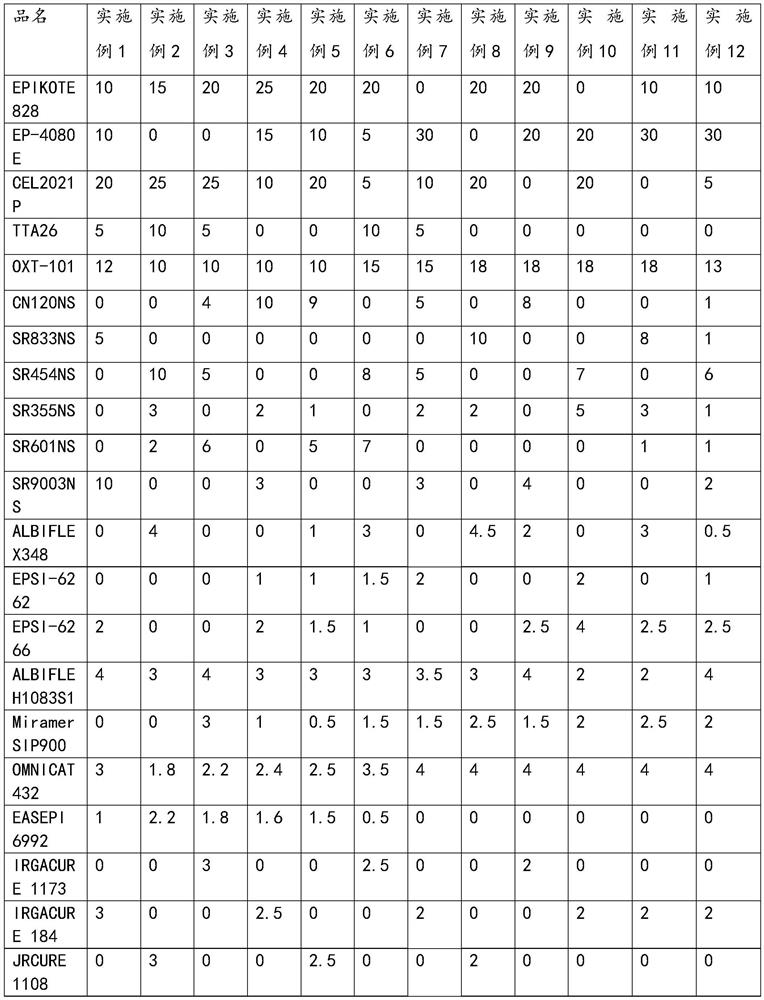

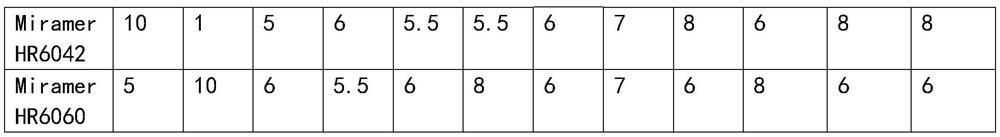

[0033] According to test material, the photocurable resin of different components is set, and the component composition of each embodiment 1-12 is as shown in table 2.

[0034] The content (mass percentage %) of various compositions in the embodiment 1-12 of table 2

[0035]

[0036]

[0037] The preparation method of the photocurable resin of embodiment 1-12 is as follows:

[0038] (1) Purchasing raw materials, storing and producing them at a temperature of 25°C, humidity below 40%, and dark conditions.

[0039] (2) Check whether the dispersing emulsifier is clean, whether the pipes and valves are in place

[0040] (3) Heat the raw materials in an oven at 60° C. for 30 minutes to reduce the viscosity for later use.

[0041] (4) Add cationic photocuring agent and free radical photocuring agent in proportion to the dispersion emulsifier, set the temperature at 60°C, 50 rpm, and stir for 2 hours.

[0042] (5) Add the free radical photoinitiator and cationic photoinitiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com