Explosion-proof shell for cable

An explosion-proof shell and cable technology, which is applied in the direction of cable joints, measuring devices, instruments, etc., can solve the problems that the cable protection cannot be effectively guaranteed, the function of the cable explosion-proof shell is single, and there is no intelligent monitoring function, so as to achieve superior explosion-proof and fire-proof function, avoid direct breakdown and explosion, and prevent fire accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

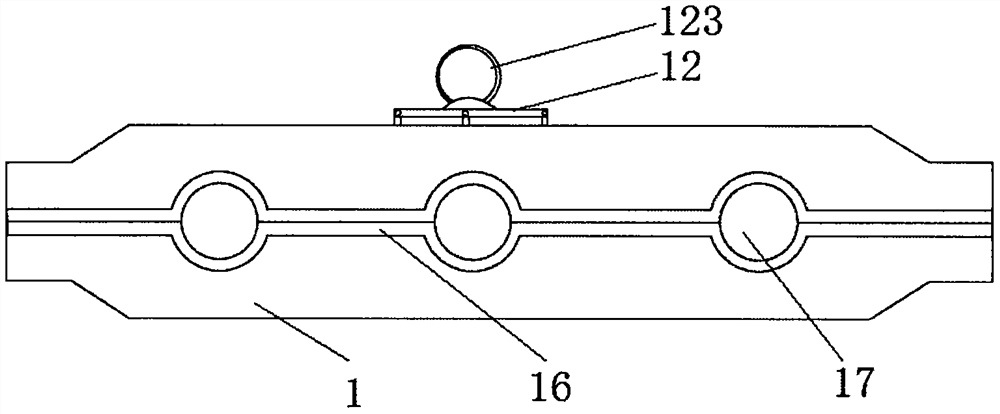

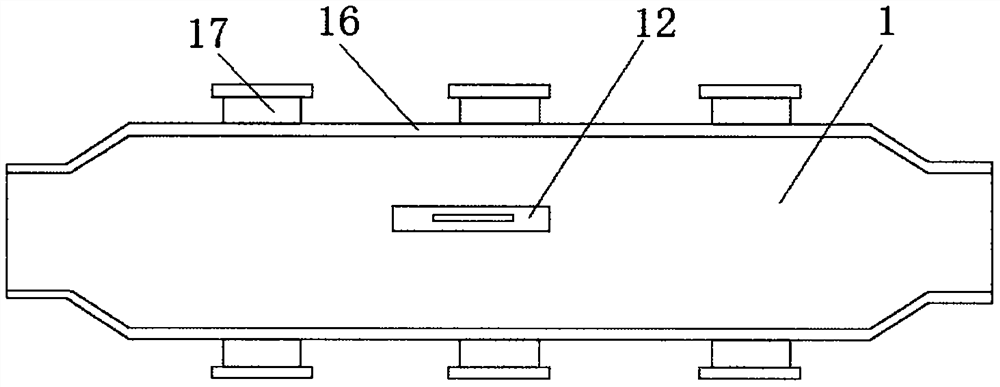

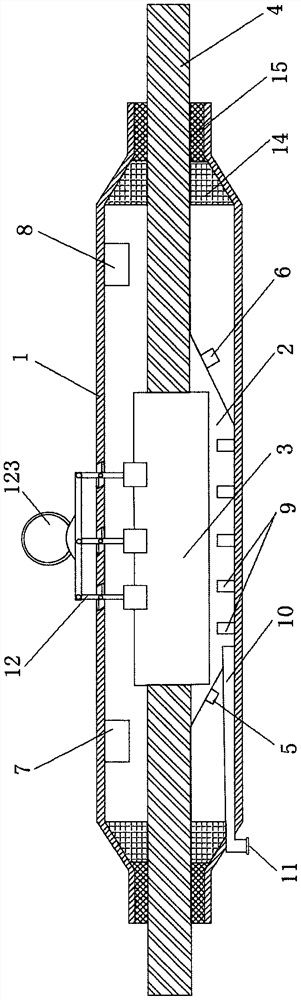

[0030] Such as Figure 1-6 As shown, this embodiment provides an explosion-proof housing for cables, including a housing 1, an explosion-proof cavity 2 formed inside the housing 1, and a cable connector 3 that matches the shape of the explosion-proof cavity. The cable connector 3 is used to realize the 4, the explosion-proof chamber 2 is used to accommodate and fix the cable connector 3. At the same time, the inner wall of the shell 1 is provided with an explosion vibration sensor 5 for detecting vibration conditions in the shell, an explosion pressure sensor 6 for detecting pressure changes in the shell, an aerosol fire extinguisher 7 for extinguishing fires, and an intermediate joint temperature for detecting cables. The temperature sensor 8. In this embodiment, a smoke alarm is installed on the inner wall of the casing. The above-mentioned explosion vibration sensor 5, explosion pressure sensor 6, temperature sensor 8 and smoke alarm are connected in parallel with a remot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com