Oxygen humidifying liquid bag and oxygen humidifying device

An oxygen humidification liquid and oxygen humidification technology, applied in the field of medical devices, can solve the problems of high cost, life-threatening, and reduced heating and humidifying ability, and achieve the effects of convenient operation and low replacement cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

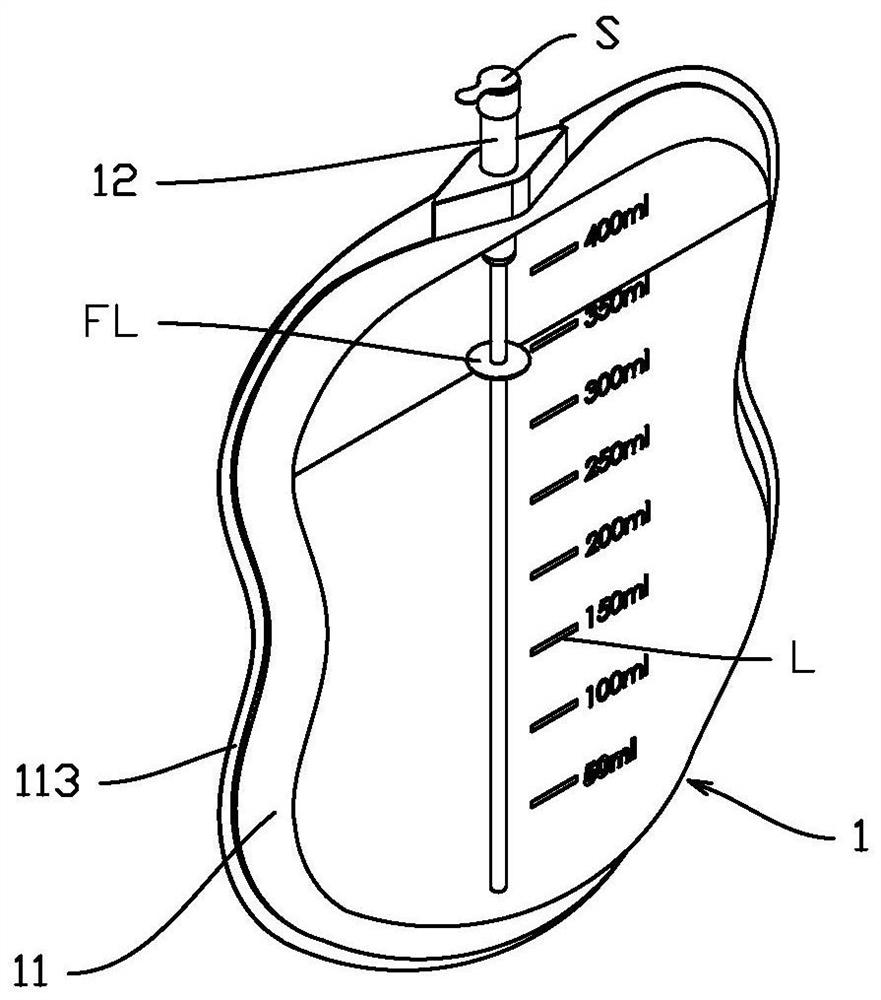

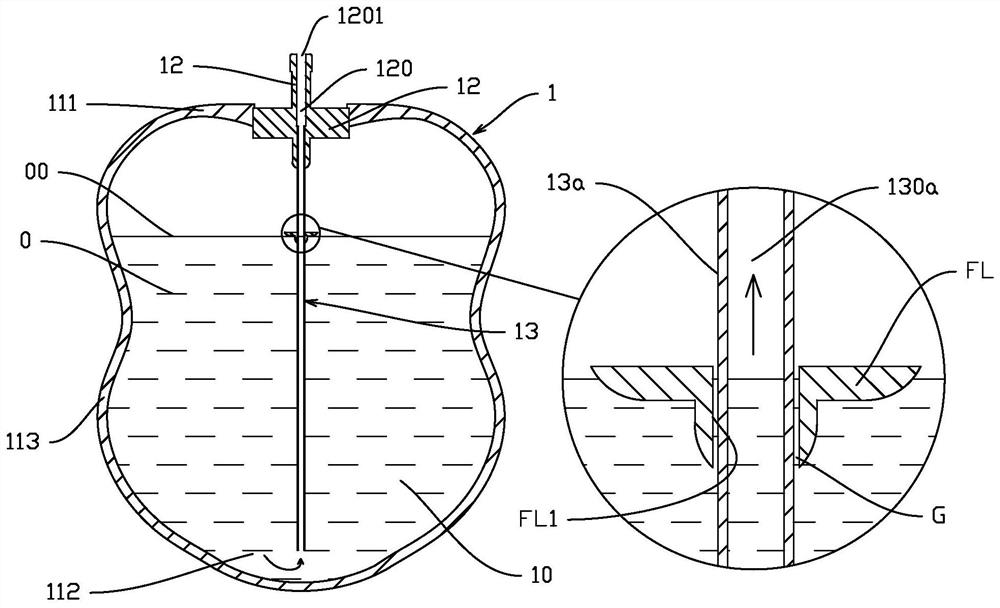

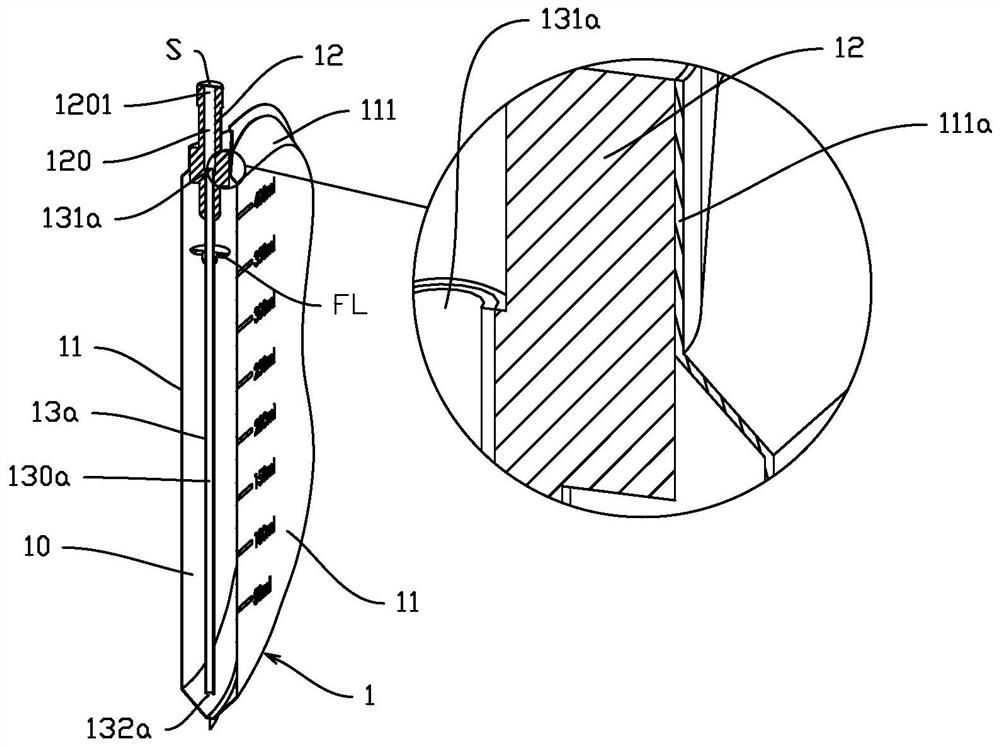

[0047] Such as Figure 1A , 1B As shown in , 1C, an oxygen humidification liquid bag of the present invention includes a bag body 11 and a mouth tube part 12, and the bag body can be cut by folding and welding two pieces of transparent medical film materials such as PP and PA or a piece of film material , the periphery of the bag body 11 can also be an opaque or frosted effect surface, Figure 1B The film material welding area 113 is shown, and the mouth tube part 12 is sealed and welded with the bag body at the same time; Figure 1C The film material welding part 111a of the upper part 111 of the bag body is shown; the mouth tube part 12 and the bag body mold base can also be injection molded once and then blow molded to form the bag body (figure omitted); part of the mouth tube part 12 is sealed and connected to the bag body The upper part 111, a part protrudes from the upper part 111 of the bag body, the internal passage 120 of the mouth tube part communicates with the inn...

Embodiment 2

[0051] Such as Figure 2A , 2B As shown, in order to make full use of the humidifying fluid as much as possible, the lower part 112 of the humidifying fluid bag is provided with a protruding portion 1120 extending downward. When the protruding portion 1120 is used vertically, it is the lowest position of the bag body 11. The passage, that is, the lower opening 132a of the slender delivery tube lumen 130a of the slender delivery tube 13a is opened in the protrusion 1120, Figure 2B Curved arrows in indicate the direction of humidification fluid flow.

Embodiment 3

[0053] Such as Figure 3A , 3B As shown, the present embodiment shows a structure of an oxygen humidification fluid bag 1. The bag body 11 is formed by welding the periphery of the bag body front film 11a and the bag body rear film 11b, and the periphery is a film material welding area 113; Two welding lines 13b are provided. The welding lines 13b are formed by welding the linear parts of the front film 11a of the bag body 11 and the rear film 11b of the bag body 11. The elongated cross-section between the welding lines 13b is an oval-shaped strip gap 130b Constitutes the humidification fluid delivery channel 13, the upper opening 131b of the strip-shaped gap 130b is in sealed communication with the inner passage 120 of the mouth tube part, and the lower opening 132b is in communication with the inner chamber 10 of the humidification fluid bag; during production, a metal rod ( Figure omitted) put into the front film 11a of the bag body 11 and the rear film 11b of the bag body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com