Anti-impact automatic tightening wrench and self-tightening method thereof

An impact-resistant and automatic technology, applied to wrenches, motor tools, wrenches, etc., can solve problems such as inattention, affecting labor efficiency, work quality and safety, and increasing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

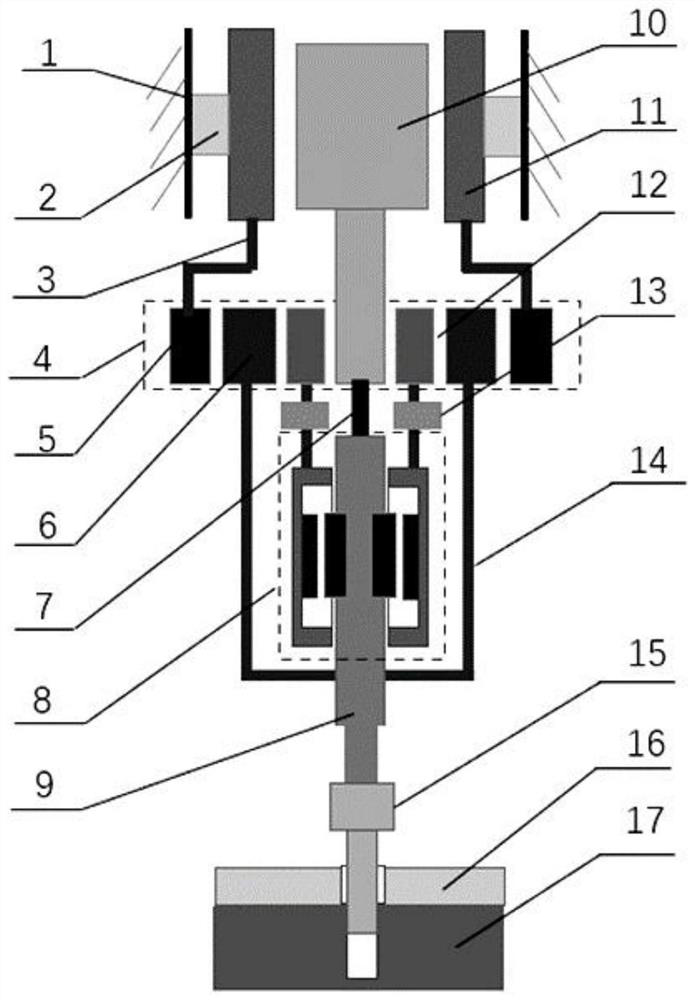

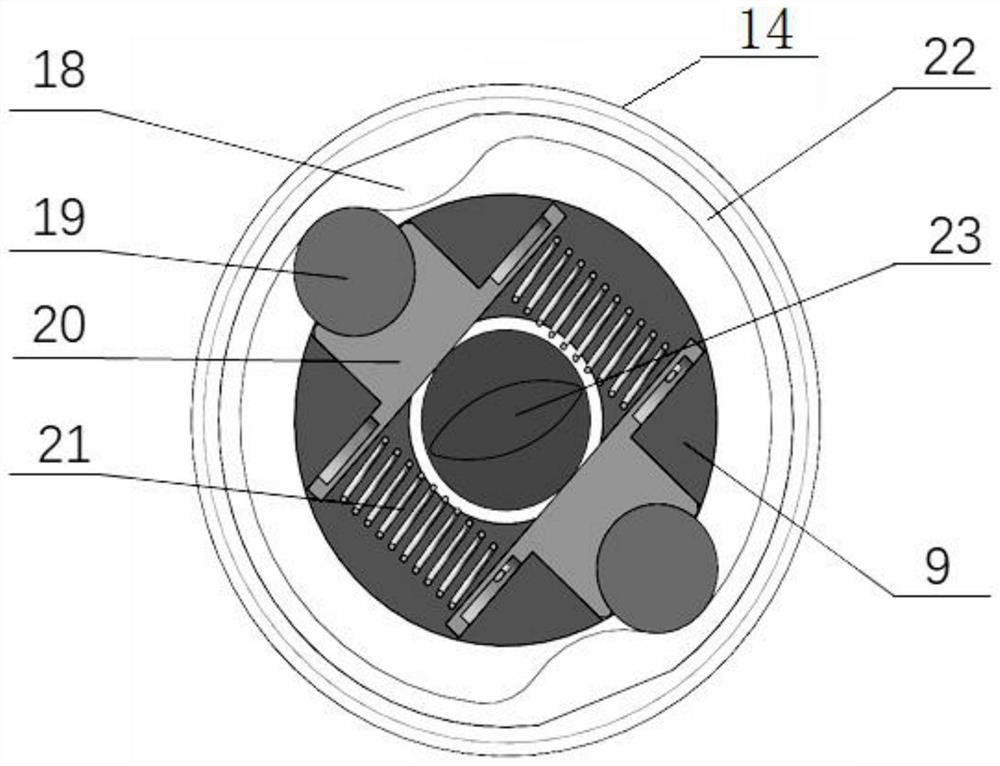

[0038] A specific embodiment of the present invention discloses an impact-resistant automatic tightening wrench, comprising: a wrench housing 1, a power assembly, a transmission assembly and an output assembly; wherein, the power assembly includes a motor outer rotor 11 and a motor inner rotor 10, The motor outer rotor 11 and the motor inner rotor 10 can rotate relatively and output the rotational speed through the motor inner rotor 10. The motor outer rotor 11 and the wrench housing 1 are assembled through the bearing 2; the transmission assembly includes a planetary gear train 4 and an overrunning clutch 13, and the output assembly includes a pulse The output assembly is connected with the power assembly through the transmission assembly; the pulser 8 can output pulse impact to the output shaft 9, and the output shaft 9 can cooperate with the object to be tightened (such as a screw) to drive the object to be tightened to rotate synchronously.

[0039] The impact-resistant aut...

Embodiment 2

[0061] A specific embodiment of the present invention provides a self-tightening method for an automatic tightening wrench, using the wrench in Embodiment 1 to tighten the bolt, comprising the following steps:

[0062] Step S1: Fit the bottom of the output shaft 9 of the wrench with the bolt 15; after the output shaft 9 is fitted with the bolt 15, the bolt 15 can rotate synchronously with the output shaft 9;

[0063] In step S1 , before work, first screw a part of the bolt 15 into the threaded hole of the base 17 .

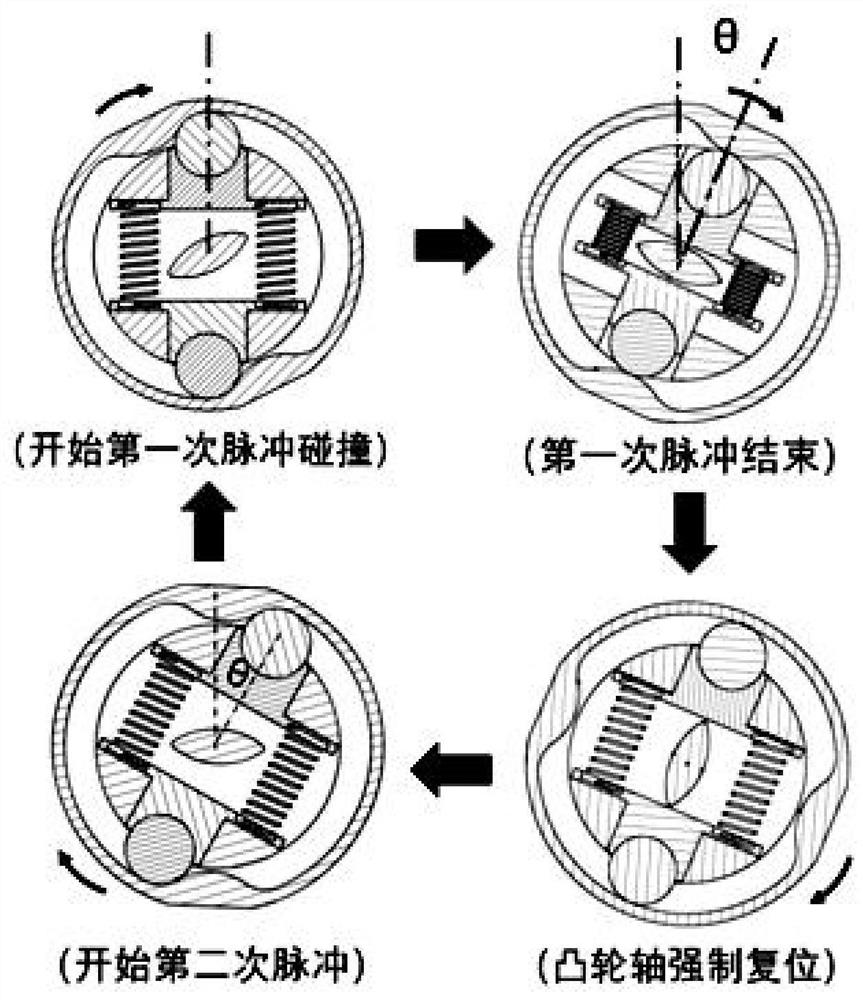

[0064] Step S2: start the motor, the motor inner rotor 10 drives the output shaft 9 to rotate through the second connecting rod 7, and pre-tighten the bolts 15; The bottom surface of the screw head of the bolt 15 is attached to the upper surface of the connected part 16 .

[0065] After the power switch is turned on, the outer rotor 11 and the inner rotor 10 of the motor begin to rotate in opposite directions under the action of the internal electromagnetic force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com