Pantograph slide plate with conductive fiber bundle structure

A pantograph sliding plate, conductive fiber technology, applied in the direction of collectors, electric vehicles, power collectors, etc., can solve the problems of increasing off-line rate, affecting the current carrying stability of the pantograph, shortening the service life of the sliding plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

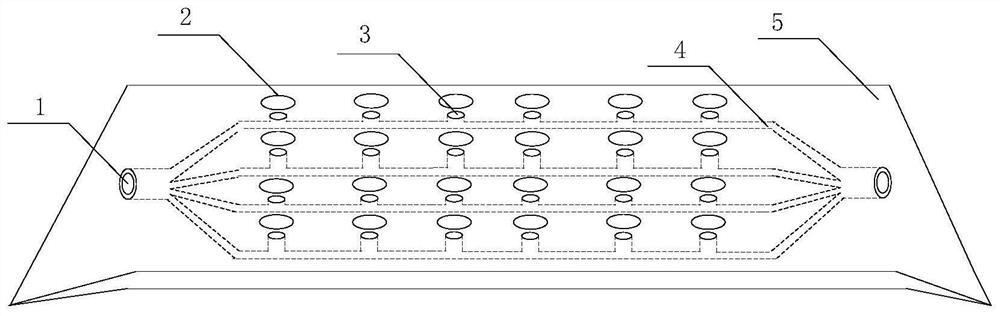

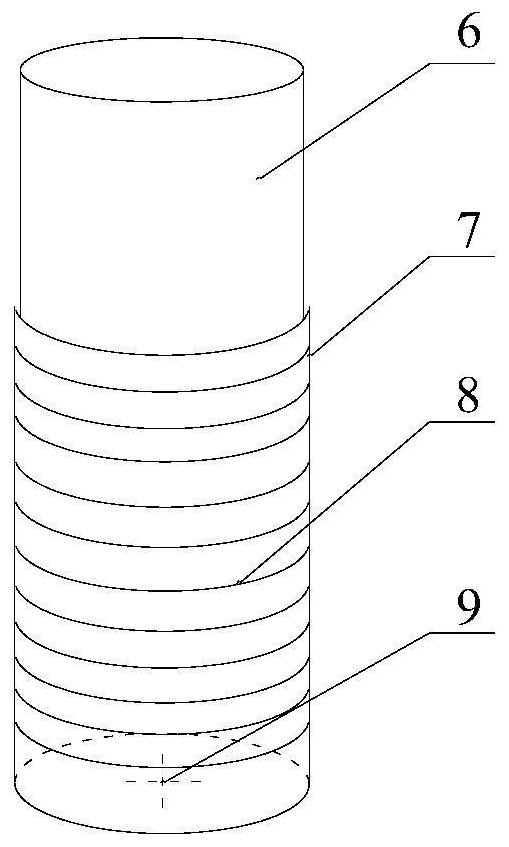

[0023] like figure 1 , 2 As shown, a pantograph slider with a conductive fiber bundle structure includes a slider base 5 and a conductive fiber bundle arranged on the slider base. The conductive fiber bundle includes a metal cylinder 7 and carbon fibers fixed in the metal cylinder Beam 6, external thread 8 is provided on the outer wall of the metal cylinder, and a plurality of screw holes 2 are provided on the surface of the base body of the skateboard, the screw holes are through holes, and the internal thread of the screw hole is in line with the metal The outer threads of the cylinder are matched; the surface of the slide base body is also provided with a plurality of cleaning holes 3, and the cleaning holes are respectively connected with the cleaning channels 4 arranged in the plate, and the cleaning channels are connected with the surface of the plate. The air supply port 1 is connected.

[0024] Wherein, after the conductive fiber bundle is installed on the base of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com