Multifunctional wine bottle packaging equipment

A packaging equipment and multi-functional technology, applied in the field of multi-functional wine bottle packaging equipment, can solve the problems of low labeling efficiency of wine bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

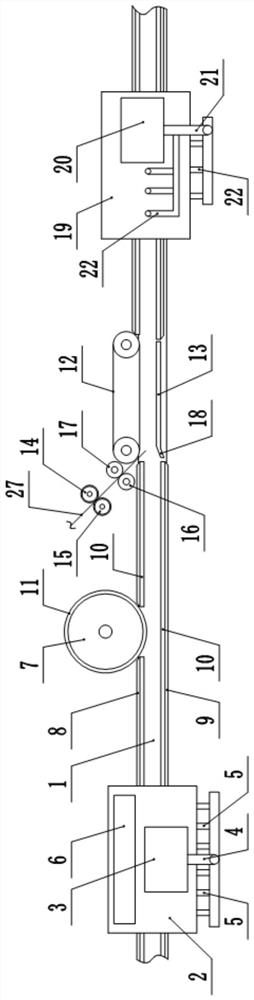

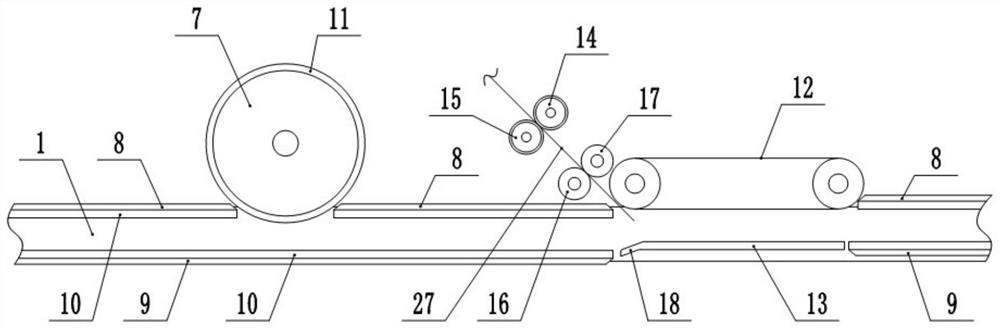

[0032] This embodiment is basically as figure 1 and figure 2 Shown: a multi-functional wine bottle packaging equipment, including a frame and a conveyor belt 1 for conveying wine bottles, and also includes an air-drying mechanism, a bottle row mechanism, a labeling mechanism and a heat-sealing mechanism arranged in sequence along the conveying direction of the conveyor belt 1 Mechanism, in the present embodiment, the transmission direction of conveyor belt 1 is from left to right.

[0033] The air-drying mechanism includes a box body-2 and a hot air blower-3. The box body-2 is fixedly installed on the frame by bolts. There is a hot air pipe-4 in communication, and the end of the hot air pipe-4 away from the hot air blower-3 is connected with several branch pipes-5, and the end of the branch pipe-5 far away from the hot air pipe-4 is connected with the side wall of the box body-2. In the example, the number of branch pipes 15 is six. The conveyor belt 1 runs through the lef...

Embodiment 2

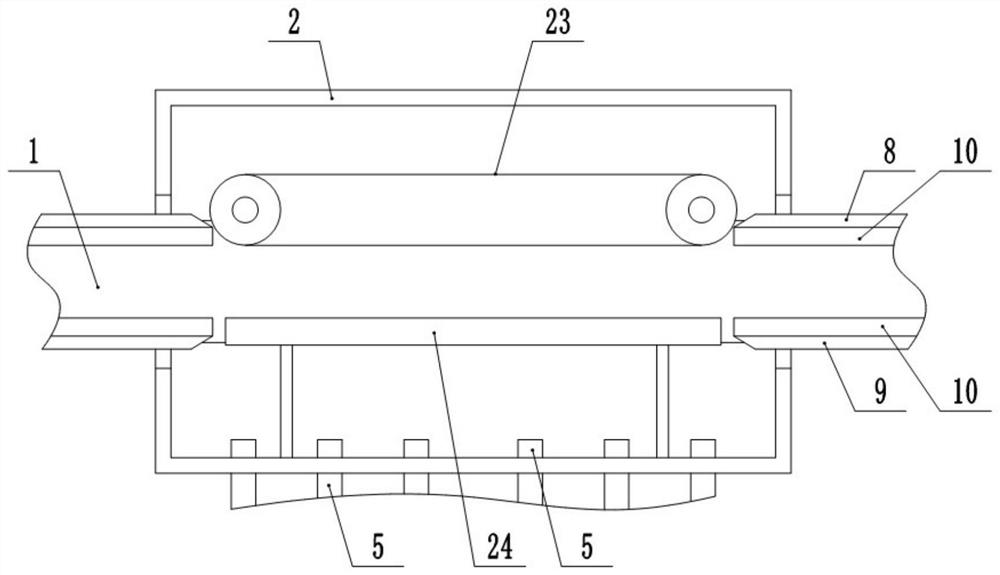

[0042] The difference between this embodiment and Embodiment 1 is that: image 3 As shown, the air-drying mechanism also includes a transmission belt two 23 and a second plate 24. The two transmission belts 23 are used to drive the wine bottle to rotate. The driving motor five that transmission belt two 23 rotates, and the driving motor five is fixedly installed on the frame by bolts, and the second board 24 is welded on the bottom wall of the box body one 2, and the distance between the two transmission belts 23 and the second board 24 is equal to the The outer diameter of the bottle (the distance between the side of the transmission belt two 23 and the second 24 of the buttress plate 24 is equal to the outer diameter of the wine bottle). Such as Figure 4 As shown, the heat sealing mechanism also includes a transmission belt three 25 and a third plate 26. The three transmission belts 25 are used to drive the wine bottle to rotate. The drive motor six that drives the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com