Steel plate length measuring device and method

A technology of length measurement and steel plate, applied in the direction of measuring device, optical device, instrument, etc., can solve the problem of low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

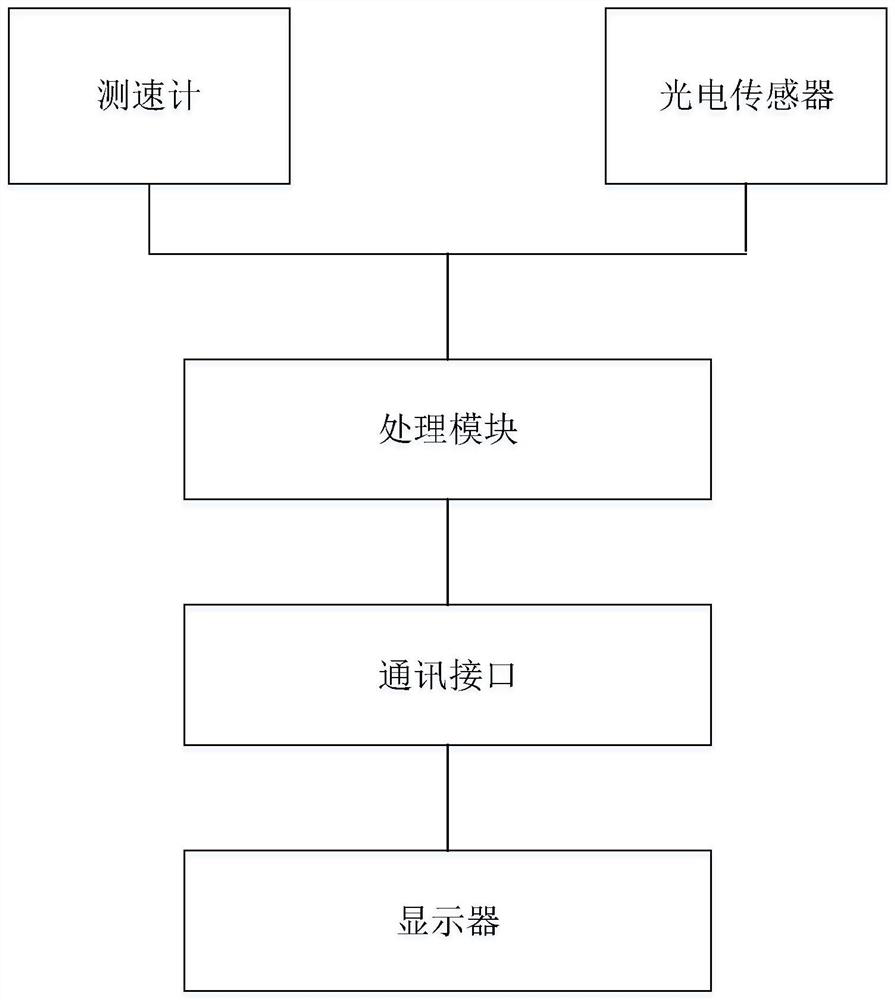

[0046] see figure 1 , figure 1 This is a schematic structural diagram of a steel plate length measuring device provided in an embodiment of the present application. Depend on figure 1 It can be known that the steel plate length measuring device in this embodiment mainly includes: a speedometer, a photoelectric sensor, a processing module, a communication interface and a display. The tachometer is used to measure the running speed of the steel plate to be measured. The tachometer in this embodiment detects the running speed of the steel plate to be measured in real time, rather than measuring the transport speed of the roller table. This structure can avoid the traditional device. measurement, which is beneficial to improve the accuracy of measurement results.

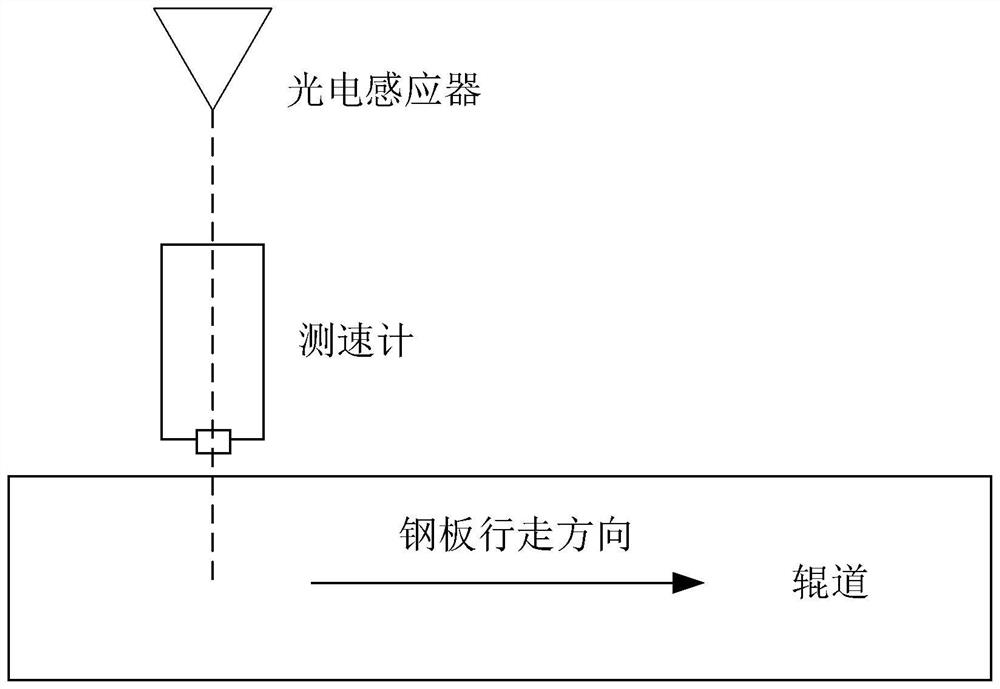

[0047] In this embodiment, the photoelectric sensor is used to collect the arrival time and departure time of the steel plate to be tested. In this embodiment, the jump signal of the photoelectric sensor is used to c...

Embodiment 2

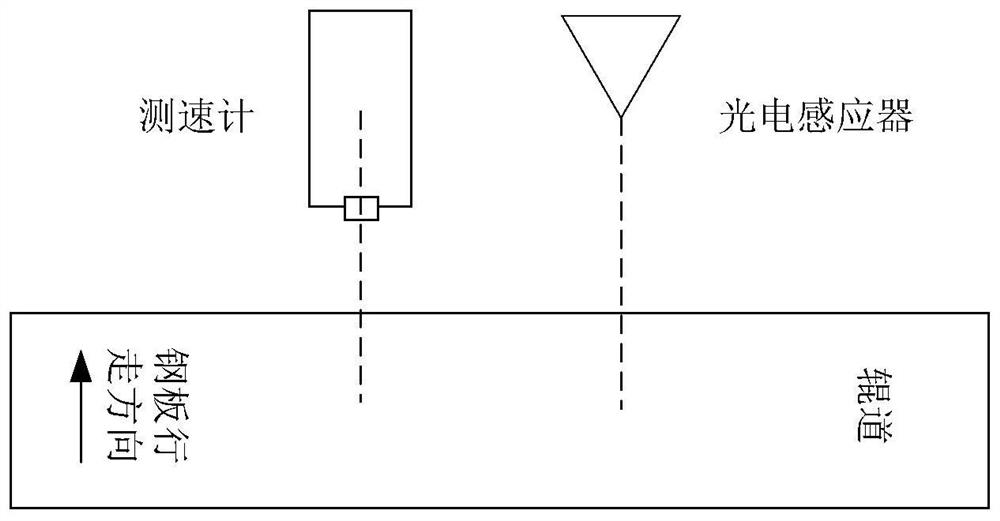

[0054] exist Figure 1-Figure 3 On the basis of the embodiment shown, see Figure 4 , Figure 4 A schematic flowchart of a method for measuring the length of a steel plate provided in the embodiment of the present application. Depend on Figure 4 It can be seen that the method for measuring the length of the steel plate in this embodiment mainly includes the following processes:

[0055] S1: After the roller table starts to run normally, judge whether the photoelectric sensor jumps from the light-passing state to the light-shielding state.

[0056] In this embodiment, it is determined whether a steel plate arrives according to the jump signal of the photoelectric sensor, and whether to start the measurement. In the normal production process, when the steel plate to be tested walks through the roller table to the position of the tachometer and the photoelectric sensor, the head first reaches this position.

[0057] If the photoelectric sensor jumps from the light-transmitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com