Microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and a manufacturing method, applied in the field of ceramic materials, can solve the problems of limited commercial application and high price, and achieve the effects of good microwave dielectric properties, low price and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

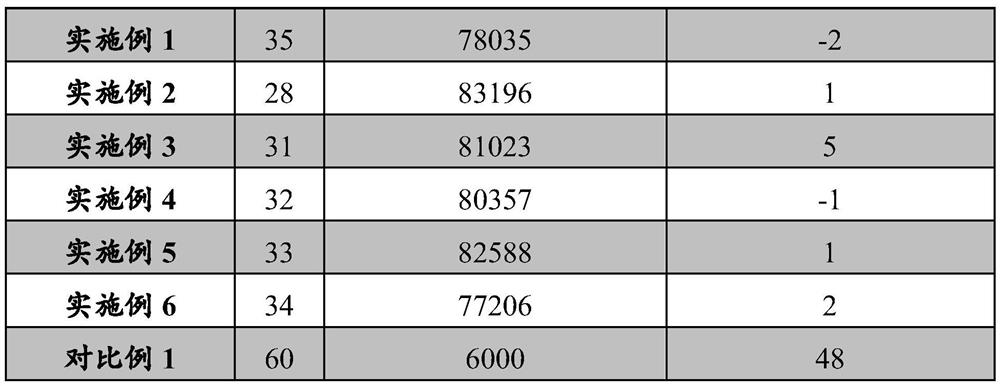

Examples

Embodiment 1

[0026] Step 1): according to a certain molar ratio, CaO, SrO, Y 2 o 3 , Nb 2 o 5 and TiO 2 The oxide is fully mixed with deionized water and dispersant;

[0027] Step 2): ball milling the above mixture for 8 hours, the particle size of the balls is 0.5 μm;

[0028] Step 3): After ball milling, dry at 90°C-120°C for 8 hours, then calcinate at 1000-1200°C for 4-5 hours, cool down to room temperature naturally, import into a pulverizer for crushing, and pass through a 40-mesh sieve to obtain powder A;

[0029] Step 4): According to a certain molar ratio, powder A, deionized water, dispersant, plasticizer, and release agent are assembled and sprayed to obtain powder B;

[0030] Step 5): After adding an appropriate amount of binder (5wt% polyvinyl alcohol solution) to the above-mentioned powder B to granulate, the powder is put into a mold, pressed under a pressure of 100 MPa, and then placed in a high-temperature furnace. Under the air atmosphere, debinding treatment for 2 ...

Embodiment 2

[0033] Step 1): According to a certain molar ratio, CaO, SrO, Nd 2 o 3 , Nb 2 o 5 and TiO 2 The oxide is fully mixed with deionized water and dispersant;

[0034] Step 2): ball milling the above mixture for 8 hours, the particle size of the balls is 0.5 μm;

[0035] Step 3): After ball milling, dry at 90°C-120°C for 8 hours, then calcinate at 1000-1200°C for 4-5 hours, cool down to room temperature naturally, import into a pulverizer for crushing, and pass through a 40-mesh sieve to obtain a powder A;

[0036] Step 4): According to a certain molar ratio, powder A, deionized water, dispersant, plasticizer, and release agent are assembled and sprayed to obtain powder B;

[0037] Step 5): After adding an appropriate amount of binder (5wt% polyvinyl alcohol solution) to the above-mentioned powder B to granulate, the powder is put into a mold, pressed under a pressure of 100 MPa, and then placed in a high-temperature furnace. Under the air atmosphere, debinding treatment for...

Embodiment 3

[0040] Step 1): According to a certain molar ratio, CaO, SrO, Sm 2 o 3 , Nb 2 o 5 and TiO 2 The oxide is fully mixed with deionized water and dispersant;

[0041] Step 2): ball milling the above mixture for 8 hours, the particle size of the balls is 0.5 μm;

[0042] Step 3): After ball milling, dry at 90°C-120°C for 8 hours, then calcinate at 1000-1200°C for 4-5 hours, cool down to room temperature naturally, import into a pulverizer for crushing, and pass through a 40-mesh sieve to obtain a powder A;

[0043] Step 4): According to a certain molar ratio, powder A, deionized water, dispersant, plasticizer, and release agent are assembled and sprayed to obtain powder B;

[0044] Step 5): After adding an appropriate amount of binder (5wt% polyvinyl alcohol solution) to the above-mentioned powder B to granulate, the powder is put into a mold, pressed under a pressure of 100 MPa, and then placed in a high-temperature furnace. Under the air atmosphere, debinding treatment for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com