A continuous annealing method for 780mpa micro-alloyed dual-phase steel

A technology of micro-alloying and dual-phase steel, which is applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of micro-alloying dual-phase steel failure, lower production efficiency, and higher process control requirements, so as to reduce strength fluctuations, Satisfies forming requirements and has excellent elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Carry out uncoiling and cleaning, the thickness of strip steel raw material is 1.2mm, and the length is 1739m;

[0039] 2) Carry out preheating, the temperature is controlled at 170 ℃;

[0040] 3) Heating, the heating rate is 2.72-2.83°C / s, the initial temperature is set to 820°C, the strip length 1 / 7 is set to 810°C, and the strip length 5 / 7 is set to 820°C;

[0041] 4) Perform soaking, the holding time is 89.2S, the initial temperature is set to 820°C, the strip length 1 / 7 is set to 810°C, and the strip length 5 / 7 is set to 820°C;

[0042] 5) Perform slow cooling, the slow cooling rate is 12.0-16.5°C / s, the initial temperature is set to 680°C, the strip length 1 / 7 is set to 690°C, and the strip length 5 / 7 is set to 680°C ;

[0043] 6) Carry out rapid cooling I, the temperature is controlled at 485°C, and the rapid cooling rate is 115-128°C / s;

[0044] 7) Carry out rapid cooling II, the temperature is controlled at 300°C, and the rapid cooling rate is 36-39°C / s; ...

Embodiment 2

[0051] 1) Carry out decoiling and cleaning, the thickness of the rolled hard coil is 1.6mm, and the length is 1364m.

[0052] 2) Carry out preheating, the temperature is controlled at 170 ℃;

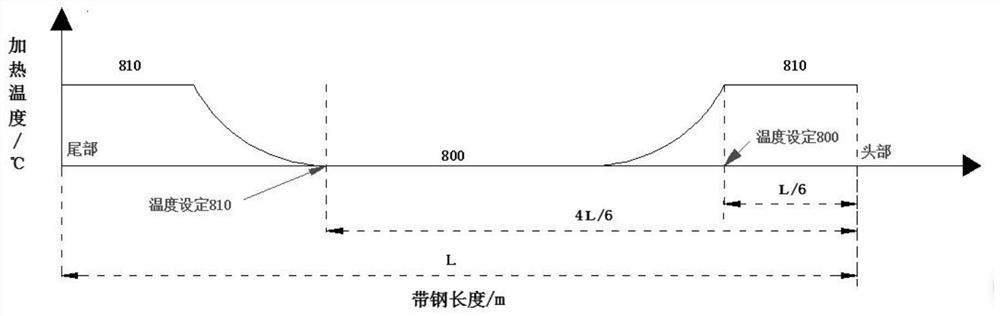

[0053] 3) Heating, the heating rate is 2.31-2.42°C / s, the initial temperature is set to 810°C, the strip length 1 / 6 is set to 800°C, and the strip length 4 / 6 is set to 810°C;

[0054] 4) Perform soaking, the holding time is 111.5S, the initial temperature is set to 810°C, the strip length 1 / 6 is set to 800°C, and the strip length 4 / 6 is set to 810°C;

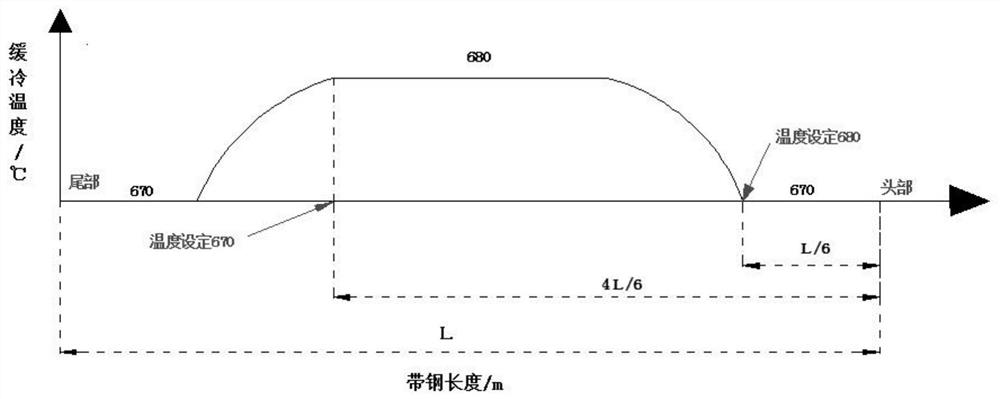

[0055] 5) Perform slow cooling, the slow cooling rate is 9.0-13.5°C / s, the initial temperature is set to 670°C, the strip length 1 / 6 is set to 680°C, and the strip length 4 / 6 is set to 670°C ;

[0056] 6) Carry out rapid cooling Ⅰ, the temperature is controlled at 455°C, and the rapid cooling rate is 107-115°C / s;

[0057] 7) Carry out rapid cooling II, the temperature is controlled at 290°C, and the rapid cooling rate is 25-28°C / s;

[...

Embodiment 3

[0064] 1) Carry out uncoiling and cleaning, the thickness of the rolled hard coil is 2.0mm, and the length is 980m;

[0065] 2) Carry out preheating, the temperature is controlled at 170 ℃;

[0066] 3) Heating, the heating rate is 1.93-2.01°C / s, the initial temperature is set to 800°C, the strip length 1 / 6 is set to 790°C, and the strip length 4 / 6 is set to 800°C;

[0067] 4) Perform soaking, the holding time is 121.6S, the initial temperature is set to 800°C, the strip length 1 / 6 is set to 790°C, and the strip length 4 / 6 is set to 800°C;

[0068] 5) Perform slow cooling, the slow cooling rate is 9.0-11.5°C / s, the initial temperature is set to 660°C, the strip length 1 / 6 is set to 670°C, and the strip length 4 / 6 is set to 660°C ;

[0069] 6) Carry out rapid cooling I, the temperature is controlled at 470°C, and the rapid cooling rate is 82.5-92.0°C / s;

[0070] 7) Carry out rapid cooling II, the temperature is controlled at 290°C, and the rapid cooling rate is 24.0-28.0°C / s;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com