Four-hole riveting ecological large frame structure and ecological slope protection structure

A sash and riveting technology, used in coastline protection, container cultivation, gardening, etc., can solve the problems of low level of mechanized construction, prominent construction difficulty, and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

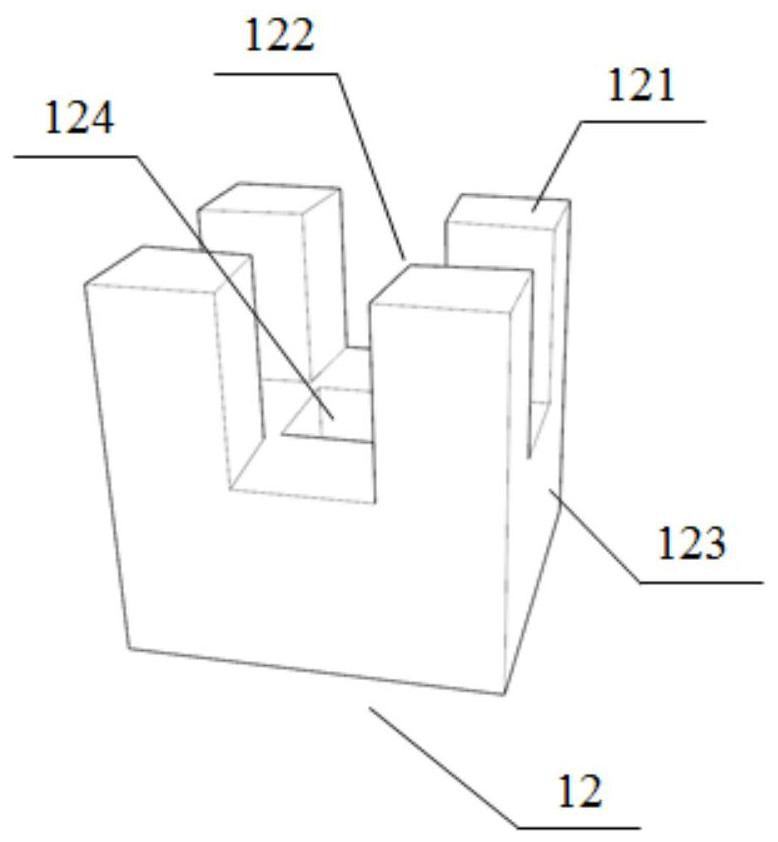

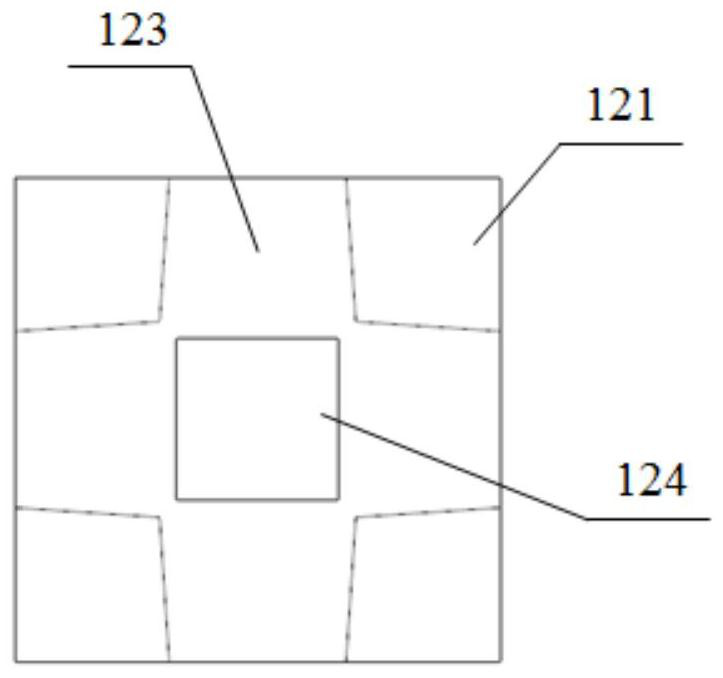

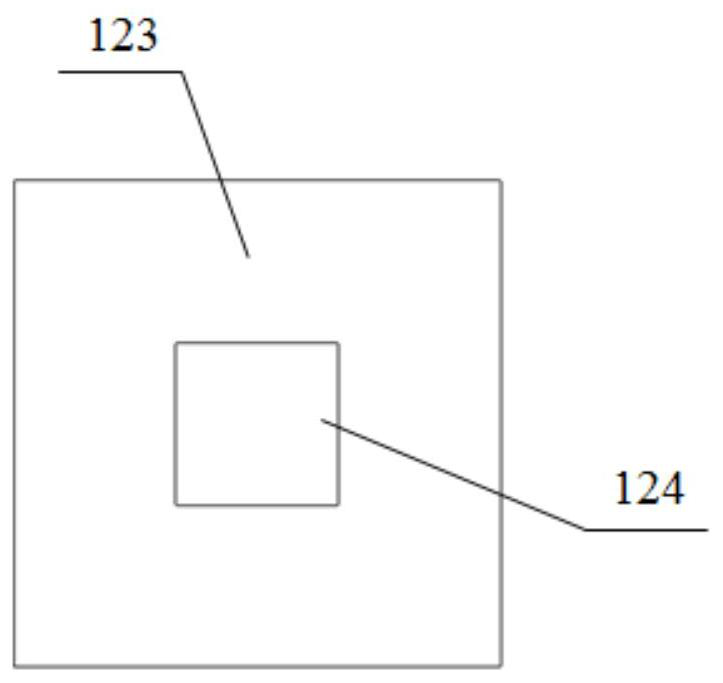

[0027] see Figure 1 to Figure 14 , a four-hole riveted ecological large grid structure 1, the porosity of the large grid structure is 45% to 55%, and a rectangular frame is used, and the rectangular frame is spliced by prefabricated components, and the prefabricated components include side Upright prefabricated slats 11 and corner connection blocks 12.

[0028] The main body of the prefabricated slat 11 is provided with a hole 111 , and the two ends of the upper part are provided with convex falcons 112 .

[0029] The corner connection block 12 has four claws 121 separated from each other on the upper part, and a buttress 123 on the lower part. The cross section of the buttress 123 is rectangular, and the four claws are respectively arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com