Green construction method of steel concrete key pin occlusion row pile integral outer wall (enclosure wall-basement exterior wall-load bearing-in-one) of reverse underground engineering

A technology for basement exterior wall and pile wall, applied in sheet pile wall, hydraulic engineering, infrastructure engineering and other directions, can solve the problems of easy leakage, weak integrity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

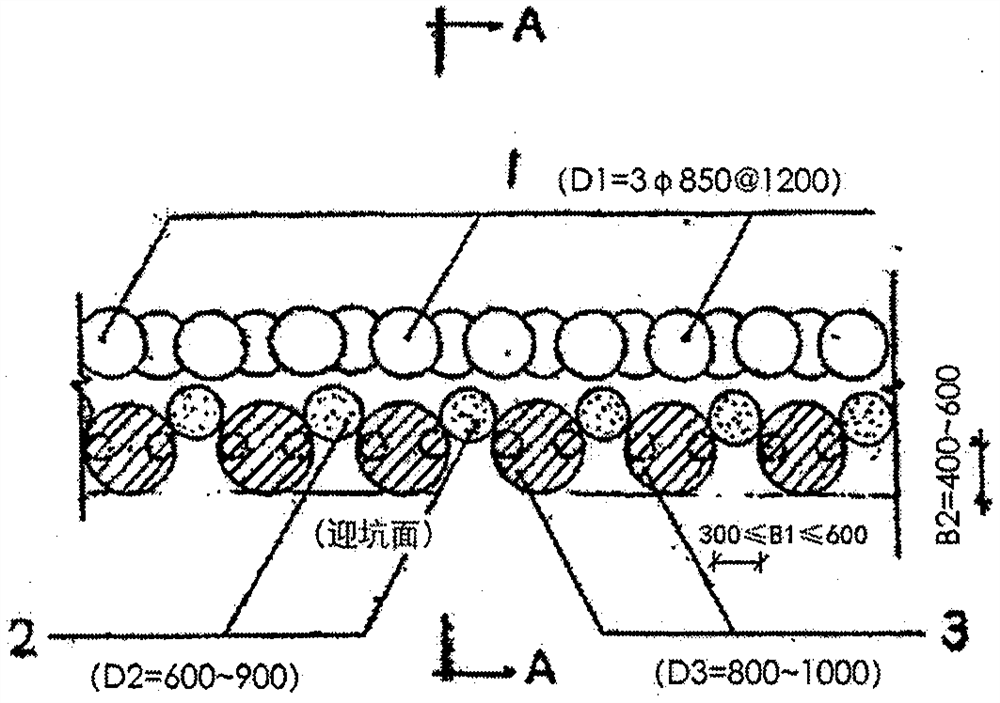

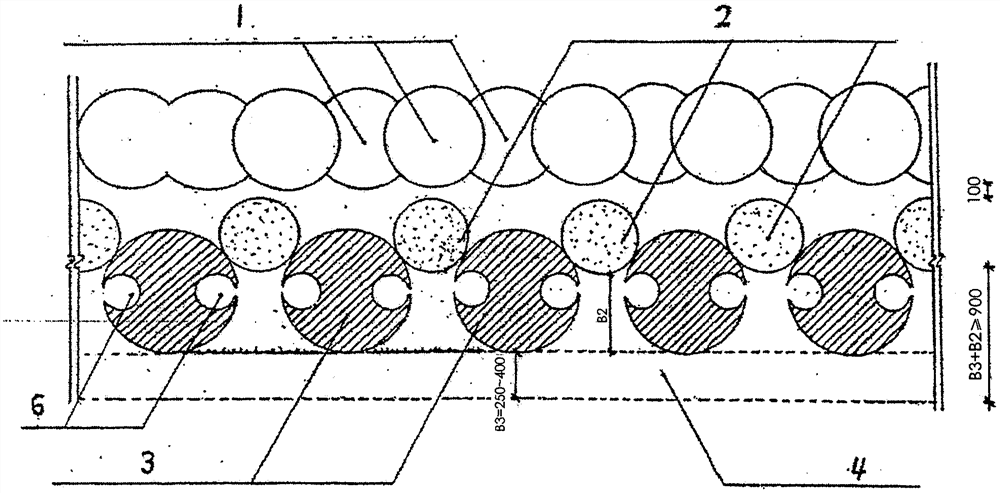

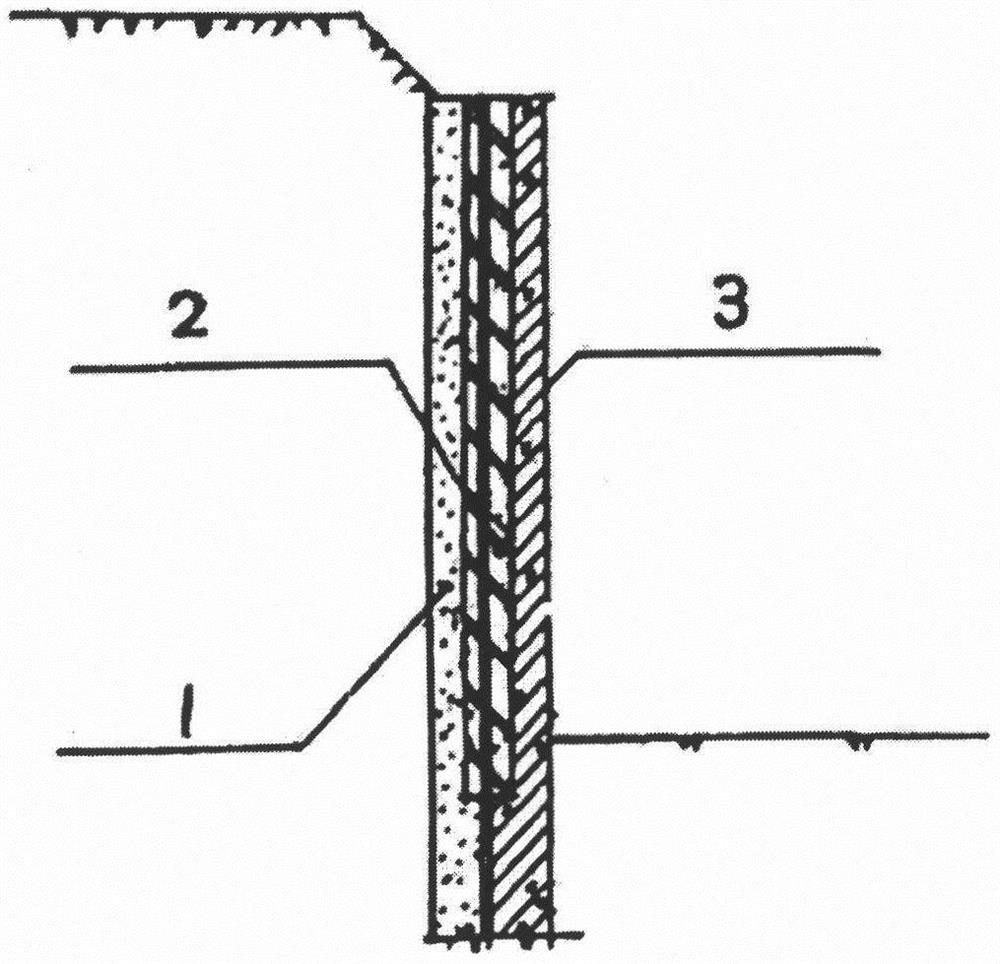

[0052] Below in conjunction with accompanying drawing (containing pile construction flow chart two) and specific implementation process, the present invention is just five main key construction procedures: 1, " the row pile enclosure wall (pile wall united type) plane layout of " key pin occlusal hole 2. Control of pile row length and vertical precision; 3. "Design and manufacture of outer circle and inner well stirrup mesh" and "Different treatment of horizontal structural reinforcement on the pile body and lower half of the pile row"; 4 , "Formation of the occlusal hole of the concrete key pin of the row of piles"; 5, "A multi-functional integral wall with three walls in one after integration and sealing" is further explained in detail (others are omitted). It should be noted that: the above-mentioned drawings are all in a very simplified form and use schematic diagrams with inaccurate scales, which are only used to facilitate and clearly illustrate the purpose and method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com