Ditching auxiliary device of novel ditcher

An auxiliary device and ditching machine technology, applied in the direction of circuit devices, battery circuit devices, transportation and packaging, etc., can solve the problems of blade wear, low efficiency, and large labor time, so as to reduce wear and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

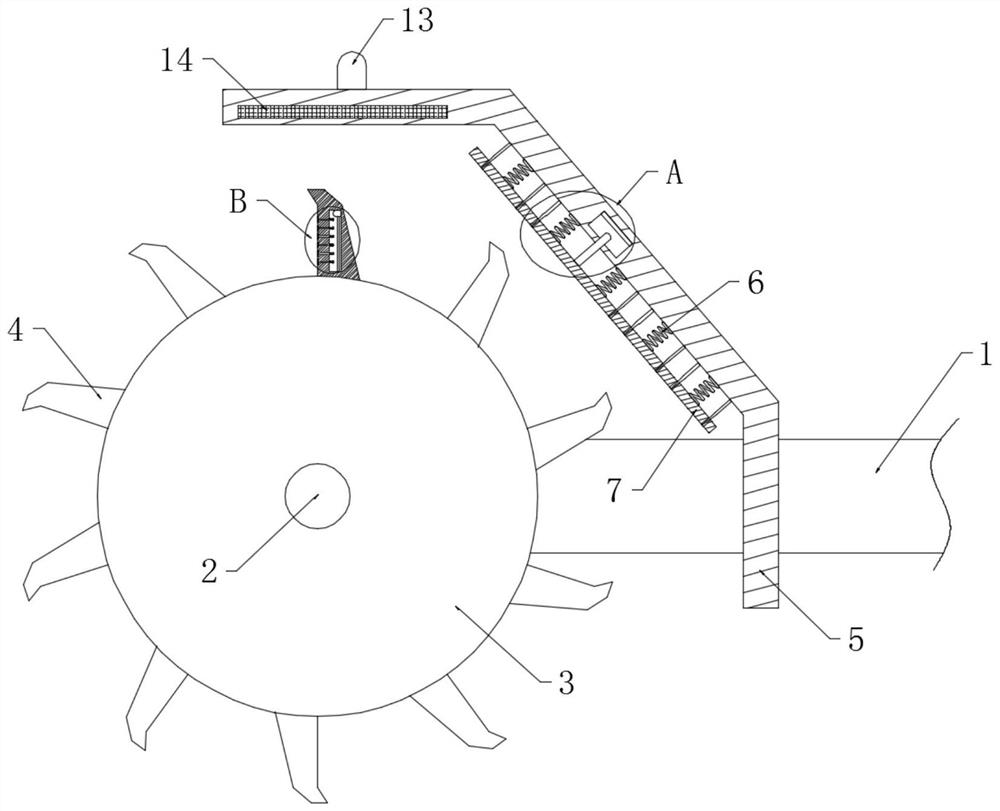

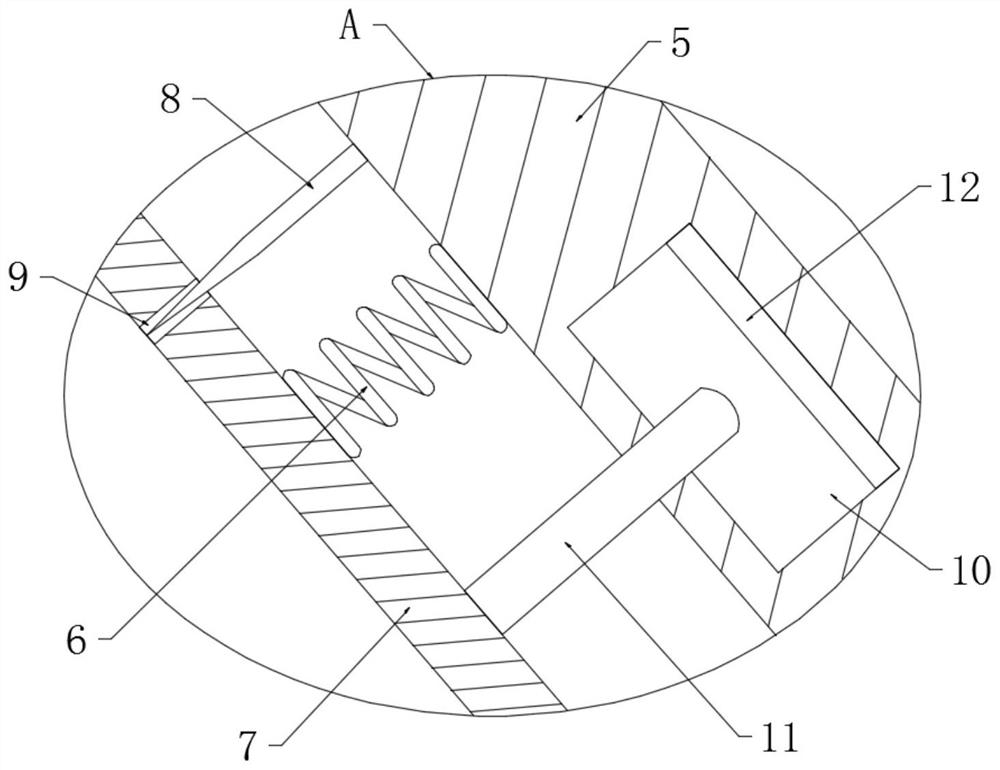

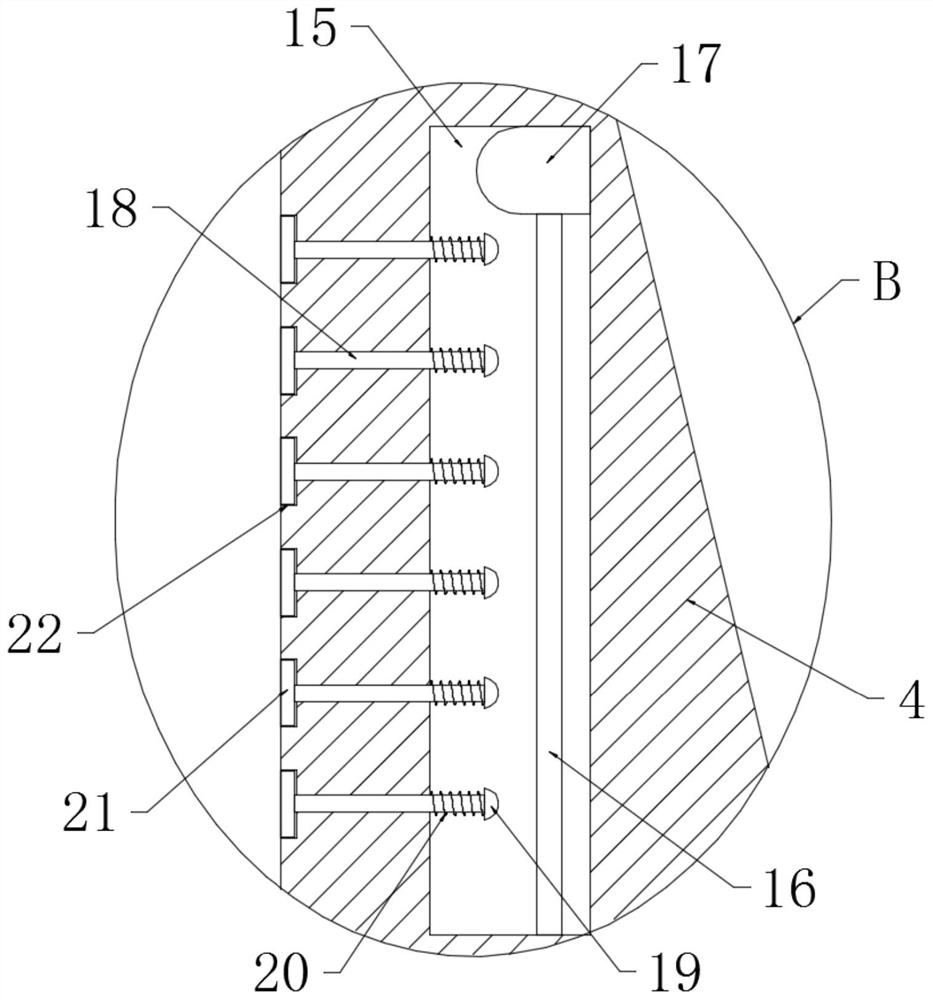

[0022] refer to Figure 1-4 , a new type of ditching auxiliary device for ditching machine, including a connecting frame 1 and a drive shaft 2 arranged on the connecting frame 1, a ditching wheel 3 is fixedly connected above the driving shaft 2, and the annular surface of the ditching wheel 3 is uniform A plurality of shovel blades 4 are welded, a protective plate 5 is welded on the connecting frame 1, and a plurality of shock-absorbing springs 6 are fixedly connected to the inclined plate surface of the side of the protective plate 5 close to the ditching wheel 3, and a plurality of shock-absorbing springs 6 One end away from the protection plate 5 is commonly connected with a fender 7, the side wall of the protection plate 5 close to the fender 7 is vertically fixed with a plurality of plastic needles 8, and the fender 7 is provided with a plurality of needle holes 9 , each pinhole 9 is slidably connected with a plastic needle 8, and a thin layer of silk cloth is adhered to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com