Reinforcement type drive-by-wire brake

A brake-by-wire and booster technology, which is applied in the direction of brakes, brake types, axial brakes, etc., can solve the problems of slow braking response and increase the braking distance of the vehicle, so as to improve the braking response speed and reduce the installation The effect of space, high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

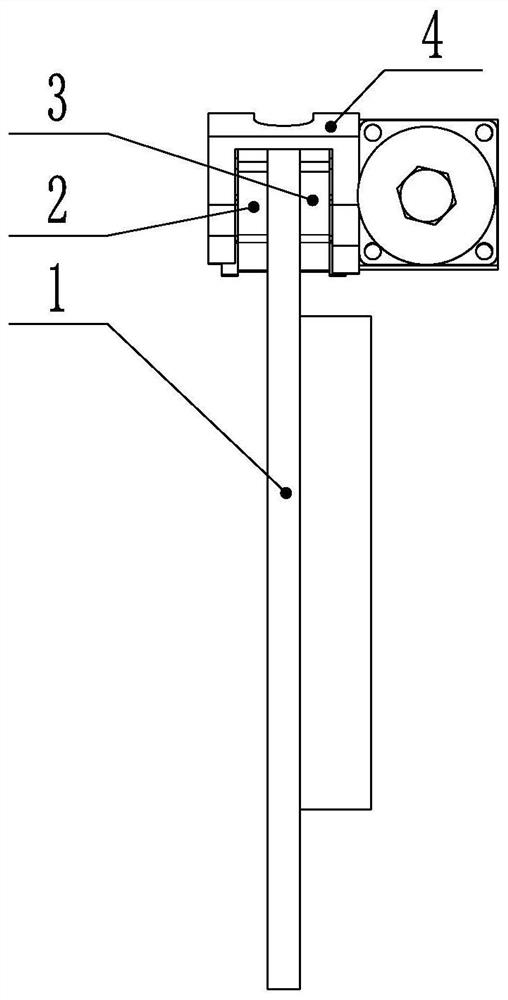

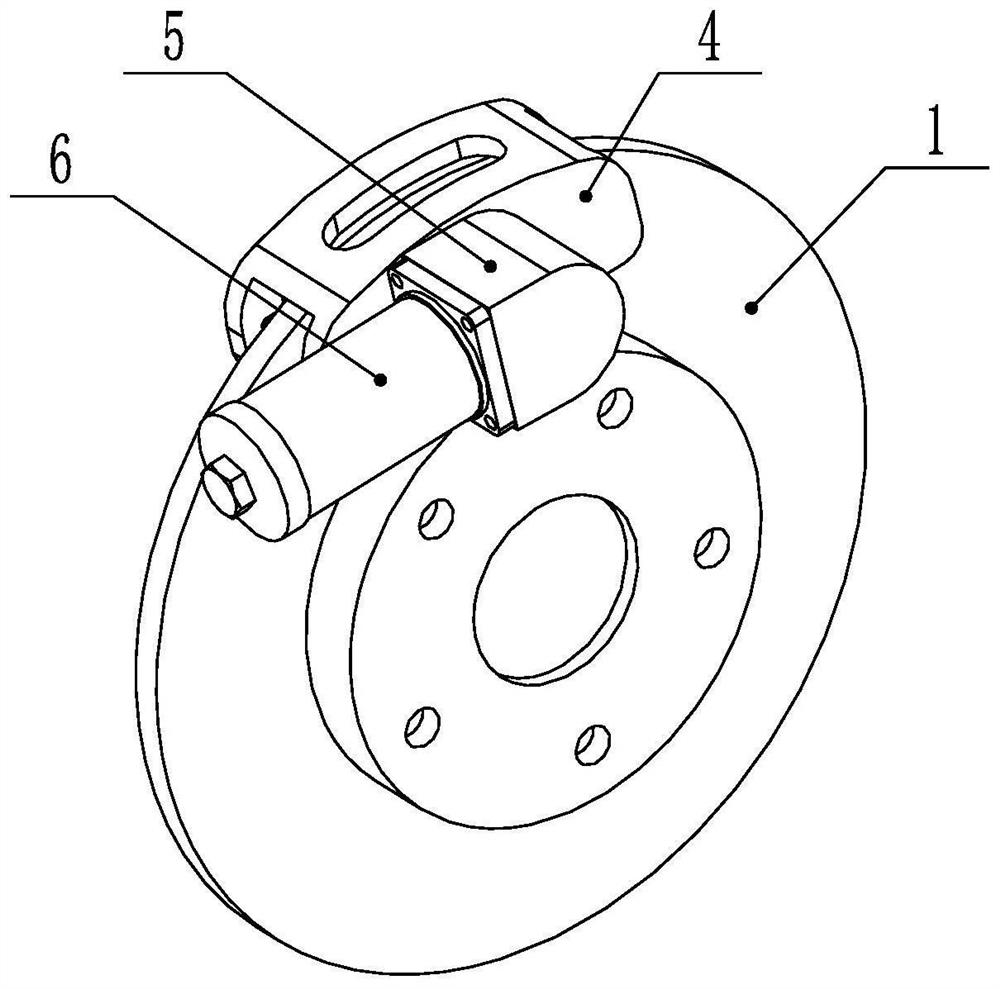

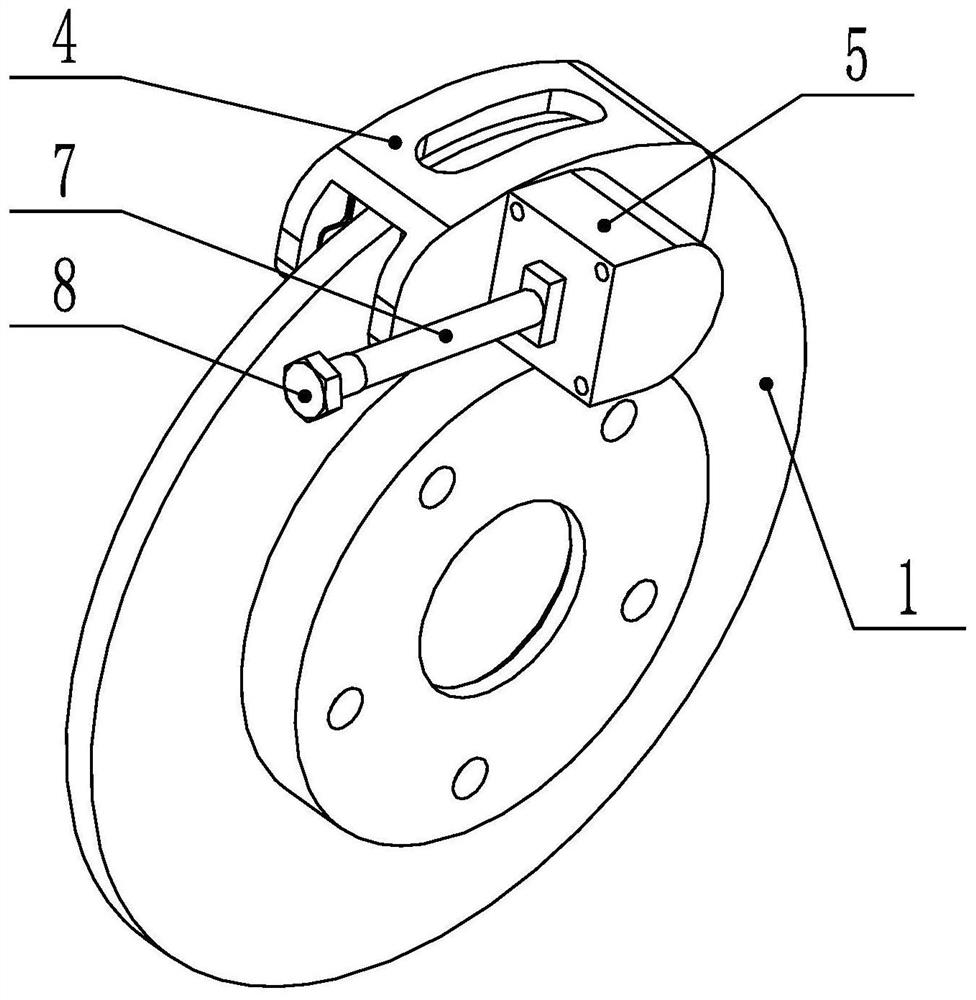

[0028] In order to clearly illustrate the technical features of this solution, the following describes this solution through a specific implementation mode and in conjunction with the accompanying drawings.

[0029] A boost-by-wire brake with a modular design such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes brake disc 1, left friction plate 2, right friction plate 3, caliper 4, cylinder body 5, electromagnetic coil assembly 6, magnetostrictive rod 7, adjusting bolt 8, wedge 9, piston 10, rubber Circle 11; described electromagnetic coil assembly 6, magnetostrictive bar 7 form magnetostrictive actuator;

[0030] The brake disc 1 is connected with the axle bolts, and the left friction plate 2 and the right friction plate 3 are installed on the left and right sides of the brake disc 1 respectively, and the left friction plate 2 and the right friction plate 3 pass through the back of the brake disc 1 respectively. The steel sheet is installed in the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com