Detection device for preventing neglected loading of scroll compressor assembly orbiting scroll

A scroll compressor and testing device technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of prolonged assembly line time, easy loss of parts, inconvenient operation process, etc. The effect of repairing and invisible faults, improving the assembly efficiency of the whole machine, and improving the assembly qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] In this embodiment, the orientation or positional relationship indicated by the terms "upper", "lower", "left", "right", "front", "rear", "upper end" and "lower end" is the orientation or positional relationship indicated by standard view projection,

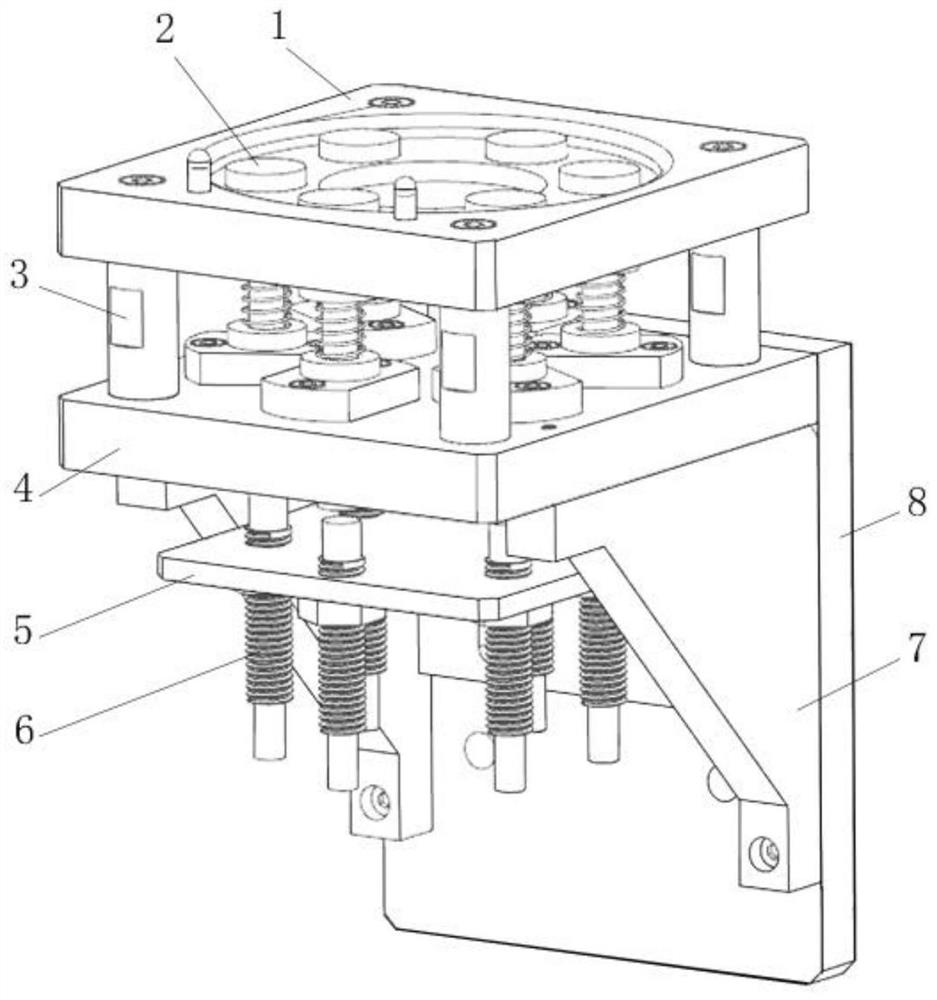

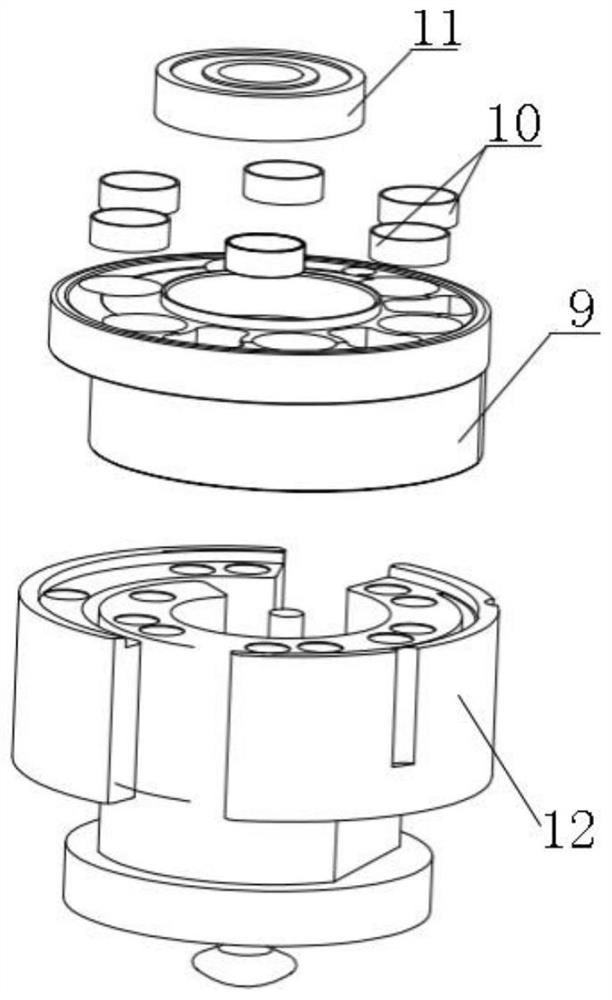

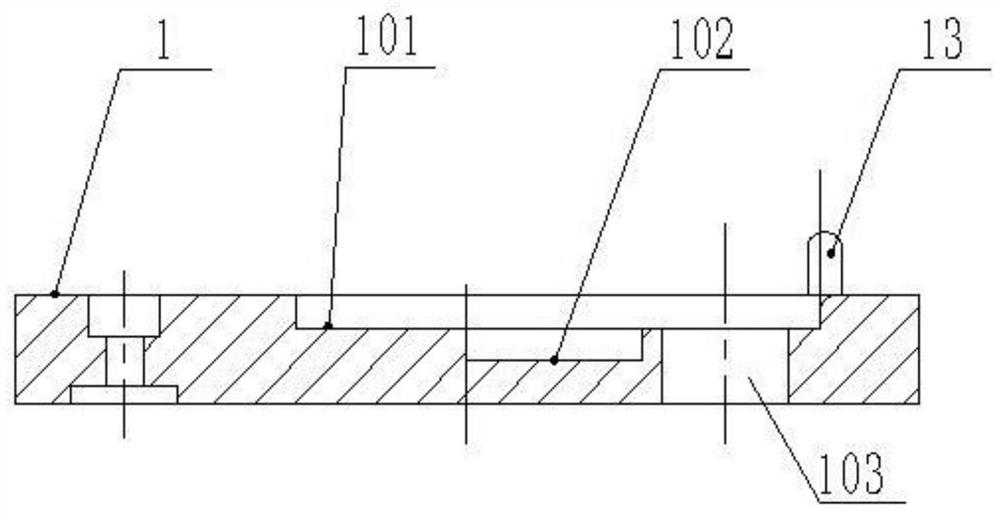

[0042] see Figure 1-Figure 14, a detection device for assembling a movable scroll leak-proof fitting for a scroll compressor, comprising a movable scroll detection disk 1, a base 4 and a displacement sensor mounting plate 5 arranged in sequence from top to bottom, the movable scroll detection disk 1 and the base 4 are connected and fastened by support columns, and the upper and lower sides of each support column are fastened with screws. The movable scroll detection plate 1 is used to place the installed movable scroll 9, wear-resistant ring 10 and bearing 11. Auxiliary tooling 12, six f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap