Square motor

A square and rotor technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of low housing space utilization, non-adjustable air gap magnetic field, permanent magnet falling off, etc., to improve stability and service life, and improve The effect of air gap space utilization and increasing the amplitude of back EMF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The present invention will be further described below with reference to the accompanying drawings and specific examples.

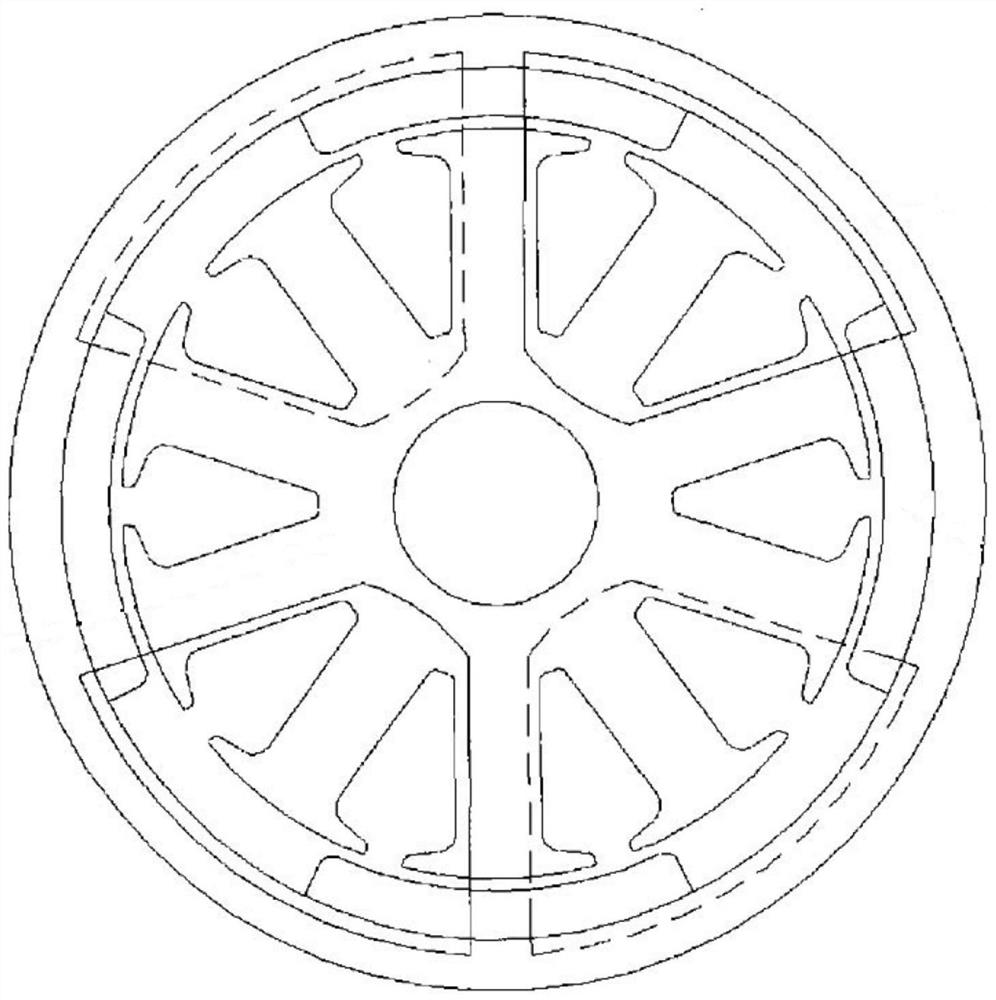

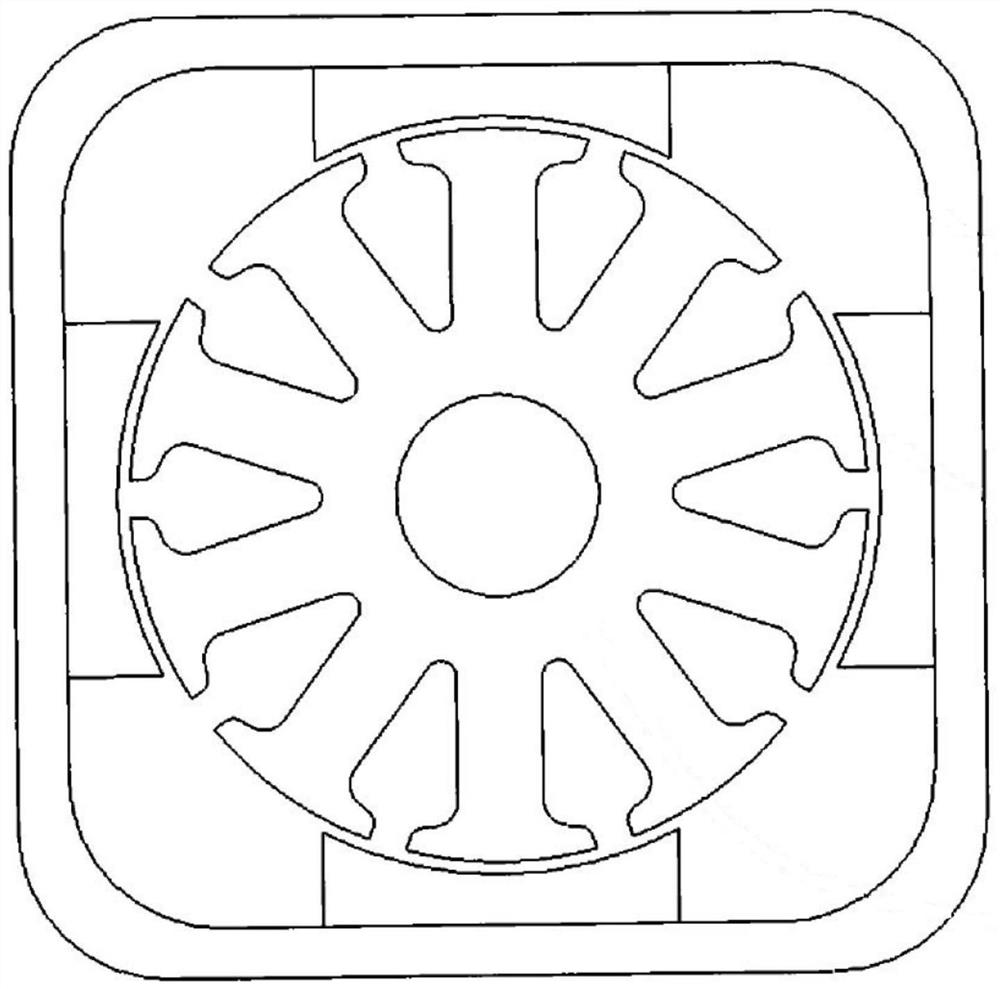

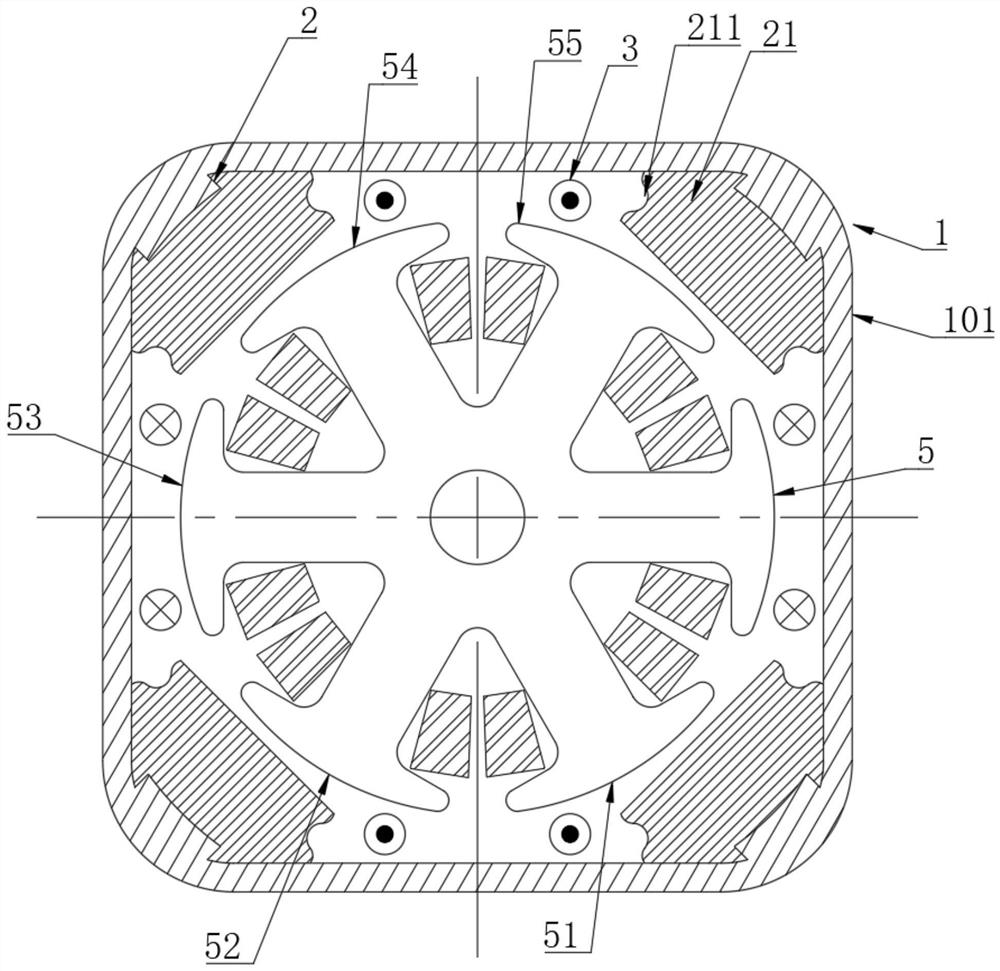

[0028]Seeimage 3 As shown, a square motor of the present invention comprises a stator and a rotor located within the stator comprising a housing 1 comprising several sidewalls 101, in adjacent two sidewalls 101 A boss 2 is provided between the boss 2, and the permanent magnet 21 is connected to the boss 2;

[0029]The permanent magnet 21 is facing a plane toward the center of the rotor, and the outer side of the rotor is an arc surface such that when the rotor is opposed to the permanent magnet 21, the outer surface of the rotor is formed between the permanent magnets 21 The air gap is evenly increased from the middle of the permanent magnet 21 to both sides;

[0030]The wire groove 211 is opened on both sides of the permanent magnet 21, and the excitation winding group 3 is rotated in the wire groove 211;

[0031]When assembled, the permanent magnet 21 with the boss ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com