Tea-flavor soybean milk beverage and preparation method therefor

A soymilk and tea-flavored technology, which is applied in the field of tea-flavored soymilk beverages and its preparation, can solve the problems of heavy bean flavor, single taste of soymilk, and sticky taste, and achieve the effects of ensuring clarity, improving drinking experience, and unique flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

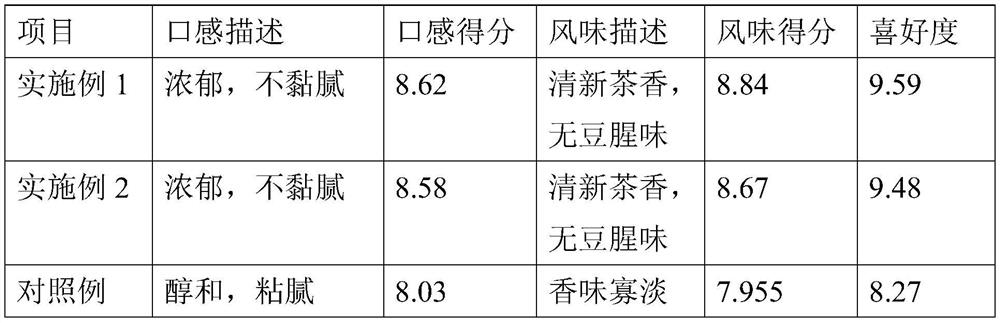

Examples

Embodiment 1

[0023] The tea-flavored soybean milk beverage described in this embodiment comprises the following raw materials in parts by weight: 15 parts of soybeans, 3 parts of rice, 2 parts of peanuts, 8 parts of tea leaves, 4 parts of rock sugar, 0.5 parts of thickener, an appropriate amount of acidity regulator, and the balance It is water, and the pH of the soybean milk beverage is 5.0 to 6.0. Wherein the tea leaves are green tea, the thickener is formed by mixing xanthan gum and sodium alginate in a ratio of 1:1; the acidity regulator is formed by combining citric acid, lactic acid and sodium citrate.

[0024] Specifically, its preparation method is as follows:

[0025] 1) Add tea leaves and water to the extraction tank at a mass ratio of 1:5 for extraction. During extraction, the amount of tannase added accounts for 0.5‰ of the tea quality. The extraction temperature is 32°C, and the extraction time is 1 hour. After the extraction is completed, raise the temperature Insulate at 80...

Embodiment 2

[0029] The tea-flavored soybean milk beverage described in this embodiment comprises the following raw materials in parts by weight: 20 parts of soybeans, 4 parts of rice, 2 parts of peanuts, 10 parts of tea leaves, 3 parts of rock sugar, 0.5 parts of thickener, an appropriate amount of acidity regulator, and The amount is water, the pH of the soy milk drink is 5.0, the tea leaves are green tea, the thickener is mixed with xanthan gum and sodium alginate in a ratio of 1:1; the acidity regulator is made of citric acid, lactic acid and sodium citrate combined

[0030] Specifically, its preparation method is as follows:

[0031] 1) Add tea leaves and water to the extraction tank at a mass ratio of 1:10 for extraction. The amount of tannase added during extraction accounts for 0.6‰ of the tea quality. The extraction temperature is 35°C and the extraction time is 1.5h. After the extraction is completed, the temperature Raise to 90°C and keep warm for 30 minutes before filtering. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com