Leaf moistening method for maintaining neutral aroma substances of flue-cured tobacco

A neutral aroma and leaf moistening technology, applied in tobacco, tobacco processing, tobacco preparation, etc., can solve the problems of poor practicability, high equipment requirements, and no improvement of flavor substances in tobacco strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

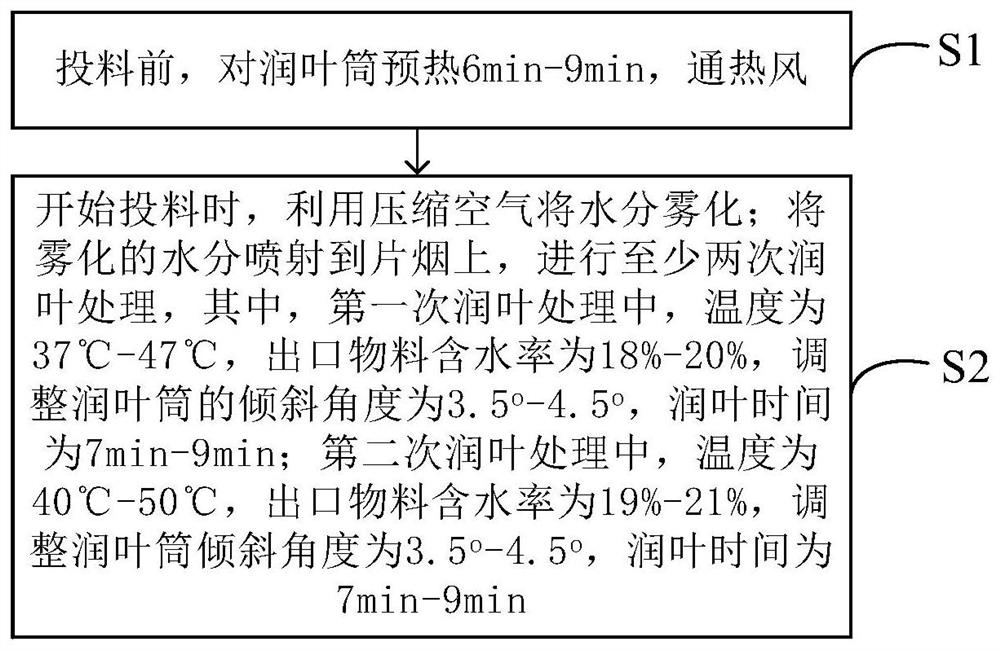

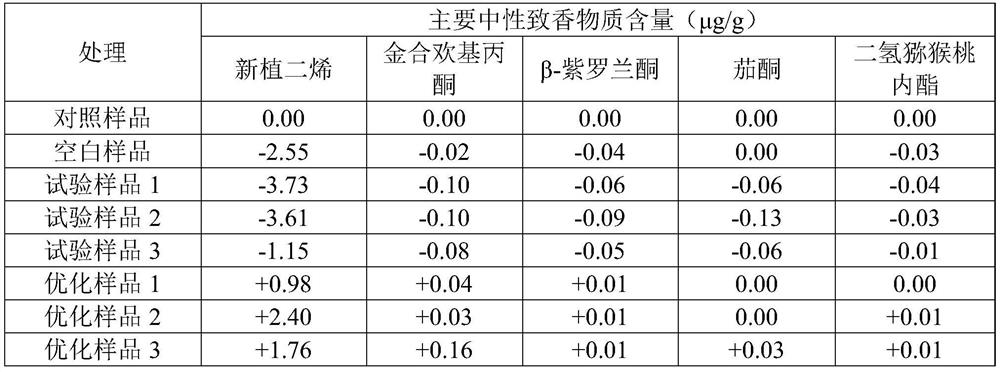

[0023] For the current leaf moistening treatment, it is mainly to set the corresponding temperature and humidity according to different parts of the tobacco, which has a certain effect on increasing the rate of large and medium slices and reducing the rate of stalks, but it does not improve the aroma of the tobacco, and it requires high equipment and is practical. Sexual problems. The invention provides a leaf moistening method for maintaining the neutral aroma substances of flue-cured tobacco. Compressed air is used to atomize the water, and a lower temperature and higher humidity are used to moisten the leaves. While meeting the requirements of the leaf threshing process, it can effectively retain The aroma su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com