Threshing and redrying pretreatment method for maintaining characteristic aroma of strong-flavor tobacco leaves

A technology of characteristic aroma, threshing and re-roasting, which is applied in the treatment of tobacco, tobacco, preparation of tobacco, etc., can solve the problems of loss of aroma components of tobacco leaves, decrease of sensory quality, loss of aroma substances of tobacco leaves, etc. Moisture content, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

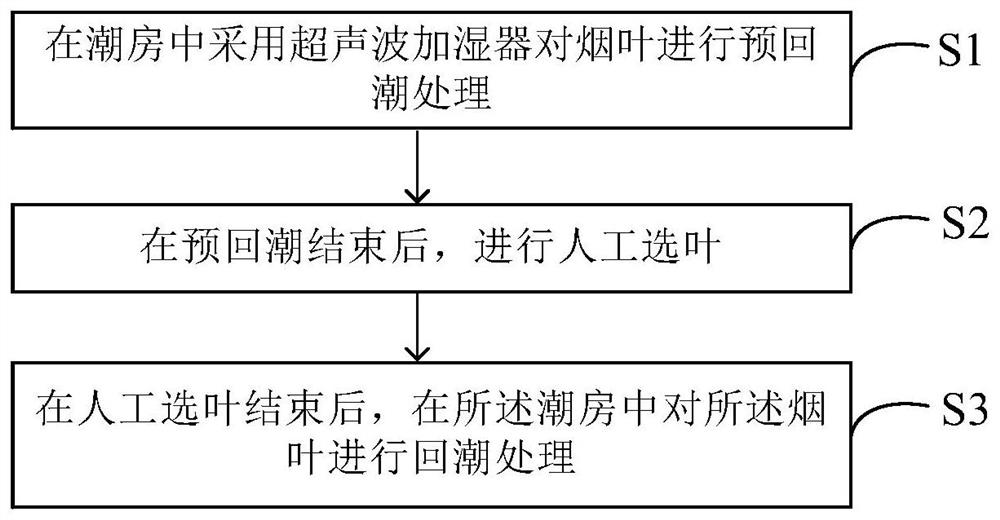

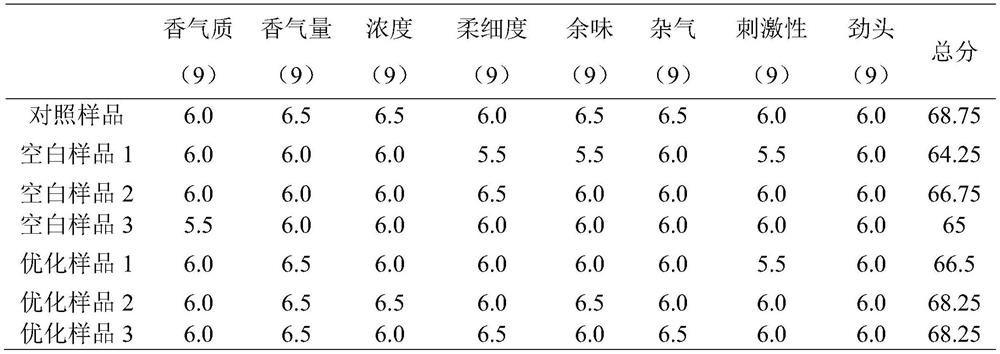

[0031] At present, the moisture content of tobacco leaves is mainly increased through subsequent high-intensity processes such as vacuum rehydration and leaf moistening. While increasing moisture content, it will cause the loss of aroma substances in tobacco leaves and the decline of sensory quality, which will have a great negative impact on the quality of later-stage cigarettes. The invention provides a pre-treatment method for threshing and re-roasting that maintains the characteristic aroma of Luzhou-flavor tobacco leaves. The ultrasonic humidifier pre-moisture stage, manual leaf selection stage, and moisture-resurgence stage ensure lower temperature and higher humidity, which can Effectively retain the chara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com