Reactive dye preparation process and distributed conveying control system thereof

A reactive dye and preparation process technology, which is applied in the field of reactive dye preparation process and its distributed conveying control system, can solve the problems of light color of printing and dyeing products, low work efficiency, high medical cost and labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

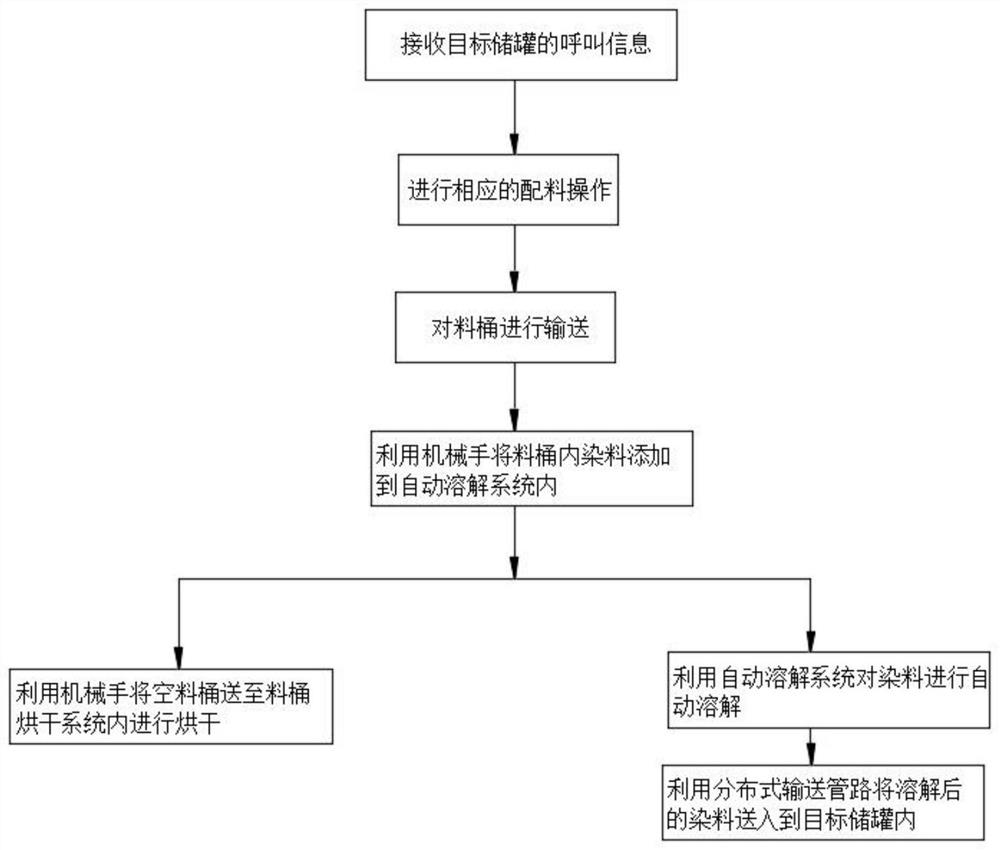

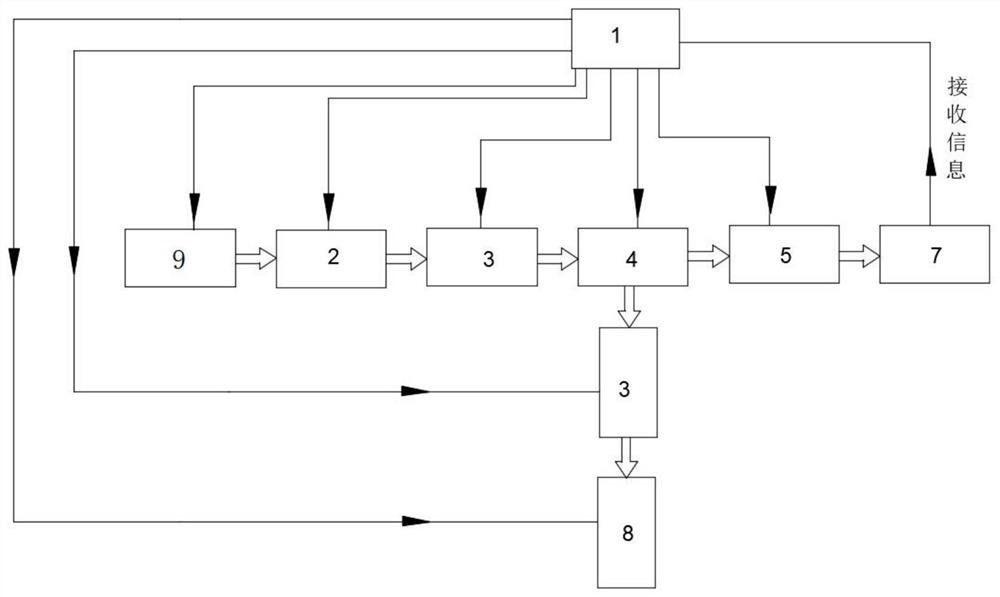

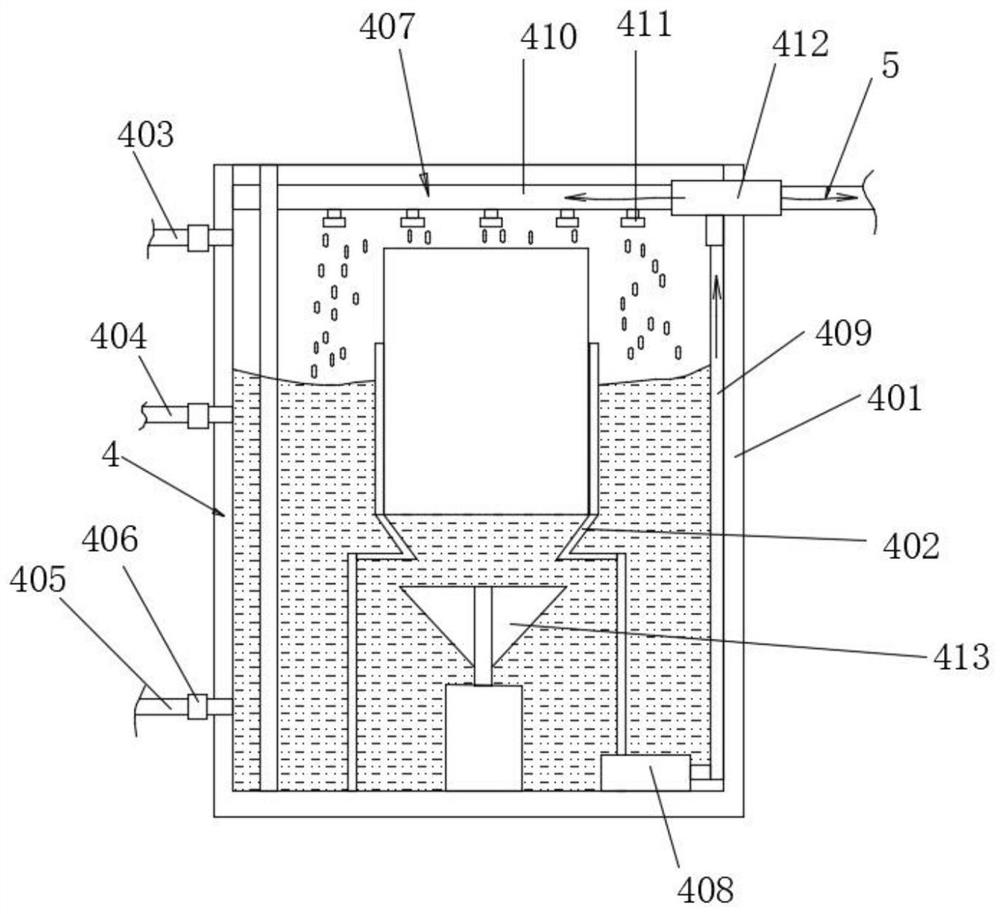

[0032] Embodiment: a kind of reactive dye preparation technology, such as Figure 1-6 shown, including the following steps,

[0033] Step 1: According to the control system in the host computer, after receiving the call information of insufficient dye solution in the target storage tank, the staff selects the corresponding dye according to the dye solution in the target storage tank, and uses the dye distribution system according to the set ratio The weight is concentrated in the bucket;

[0034] Step 2: Use the dye conveying device to transport the material drum containing the dye to the designated material picking position, and then use the manipulator to send the material tank on the material picking position to the dissolving corner motor bracket in the dissolving cylinder for tightening and positioning; then dissolve The cylinder is closed for feeding operation;

[0035] Step 3: After the feeding operation is completed, the dissolving tank is opened, and the empty mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com