Crusher for construction machinery

A technology for construction machinery and crushers, applied in grain processing, separation of dispersed particles, chemical instruments and methods, etc., can solve problems such as air pollution, incomplete crushing of materials, failure of crushers to perform circular crushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

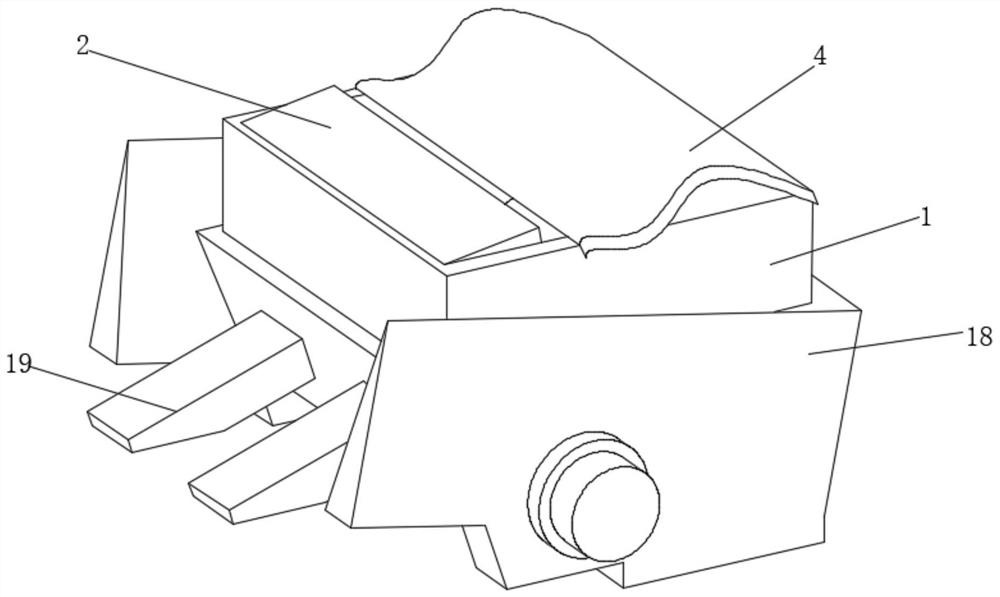

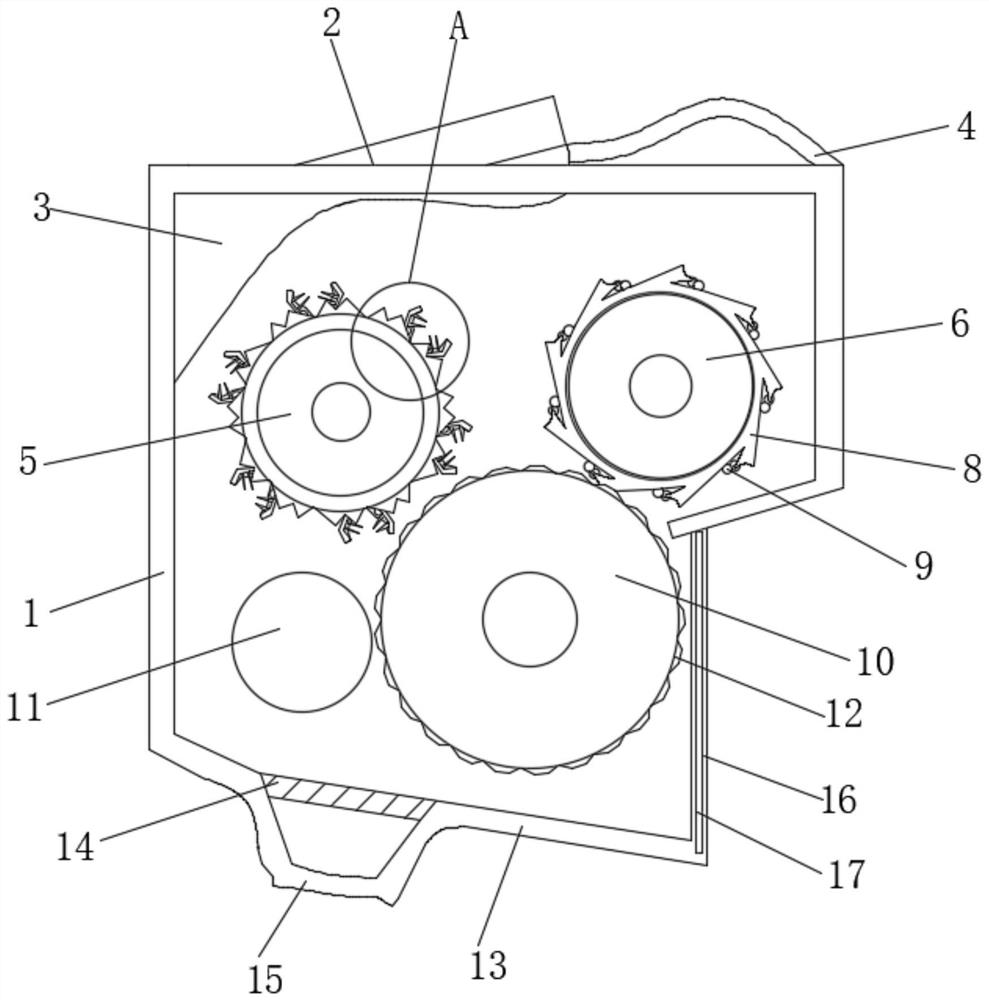

[0029] see Figure 1-2 , the present invention provides a technical solution: a crusher for construction machinery, comprising a box body 1, the top of the box body 1 is provided with a material inlet, the inner surface of the material inlet is rotatably connected to a box cover 2, and the box cover 2 The bottom is fixedly connected with a buffer pad 3, the right side of the top of the box body 1 is slidingly connected with a semi-permeable plate 4, the inner surface of the box body 1 is respectively connected with a crushing shaft 5 and a reverse shaft 6, and the outer surface of the crushing shaft 5 is evenly connected There is a fixing mechanism 7, the outer surface of the reverse shaft 6 is evenly and fixedly connected with a reverse baffle 8, the outer surface of the reverse baffle 8 is evenly and fixedly connected with balls 9, the inner surface of the box body 1 is located near the crushing shaft 5 One side is connected with an auxiliary roller 10 for rotation, and the ...

Embodiment 2

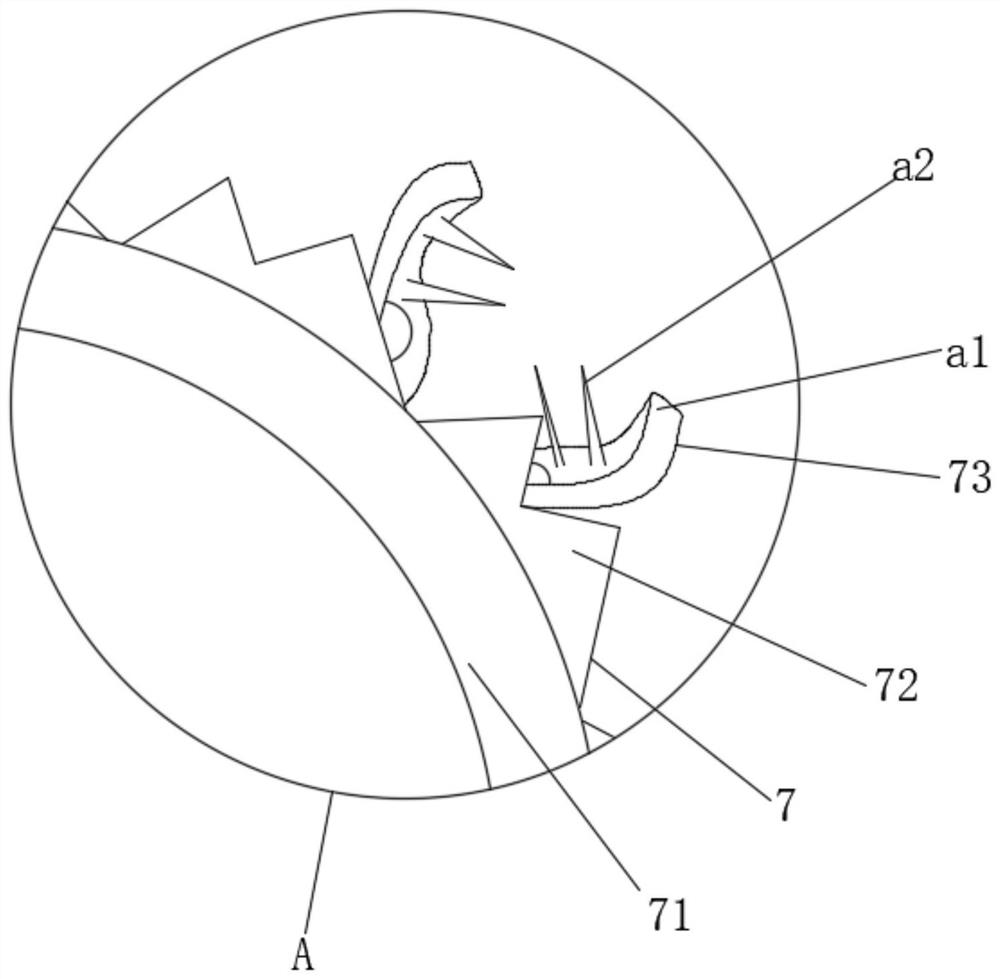

[0031] see Figure 2-4 , the present invention provides a technical solution: the fixing mechanism 7 includes a circular casing 71, the inner surface of the circular casing 71 is fixedly connected with the outer surface of the crushing shaft 5, and the outer surface of the circular casing 71 is evenly and fixedly connected with a cone The outer surface of the shaped tooth 72 and the tapered tooth 72 are uniformly and fixedly connected with a clamping assembly 73 . After the material is fixed, it can be crushed. Through the cooperation of the conical teeth 72 and the auxiliary roller 10, the distance between the two is shortened, the friction to the material is increased, and the crushing force is increased. After the internal puncture assembly a2 clamps the material, it is not easy to fall off, and it is fixed and directly sent between the crushing shaft 5 and the auxiliary roller 10 .

[0032] The clamping assembly 73 includes an arc-shaped blade a1, the bottom of which is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com