Mechanical arm clamping hand cleaning tank capable of achieving rapid discharging

A technology of a robotic arm and a cleaning tank, which is applied in the field of semiconductor manufacturing equipment, can solve the problems of hand-pinch pollution and cross-contamination of the robotic arm, and achieve the effects of facilitating the jet pipe and the liquid jet pipe, improving the applicability, and facilitating the disassembly and adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

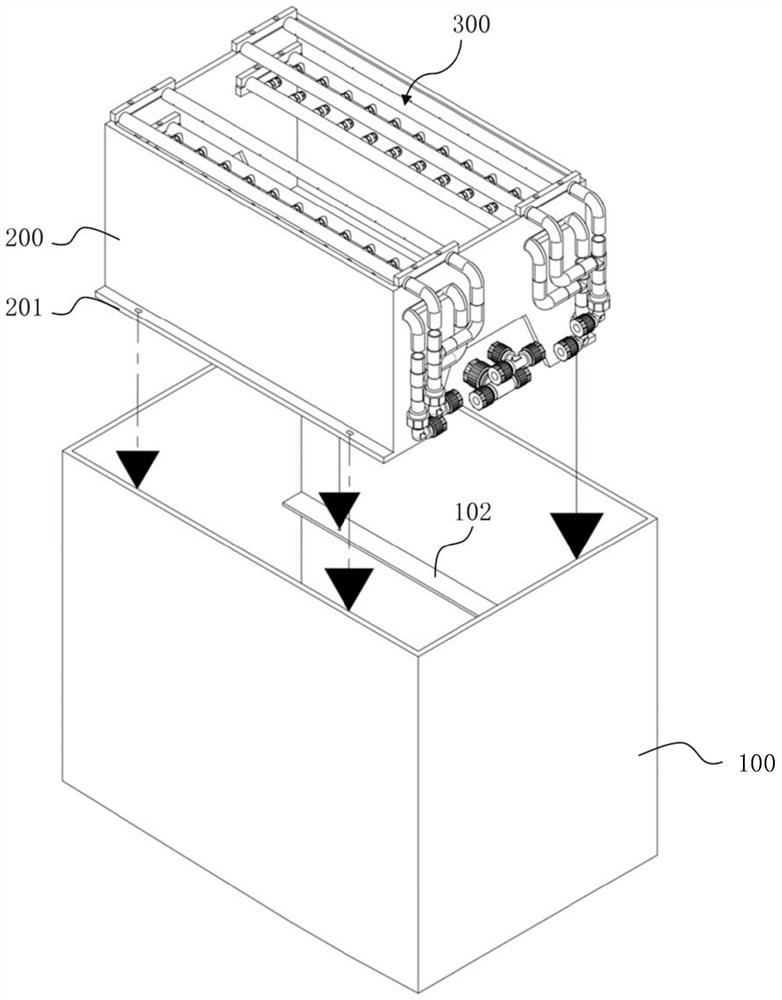

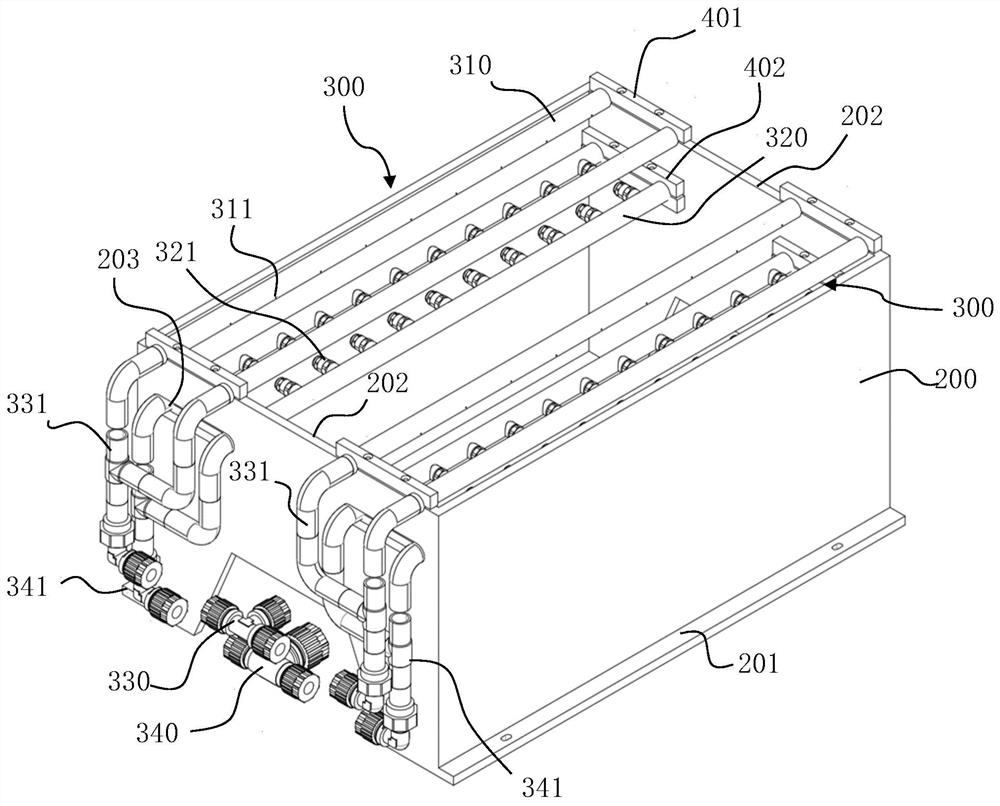

[0020] Such as Figure 1 to Figure 3 As shown, the fast-discharging cleaning tank of the robotic arm gripper of the present invention includes an outer tank body 100 , an inner tank body 200 and two spray pipe assemblies 300 .

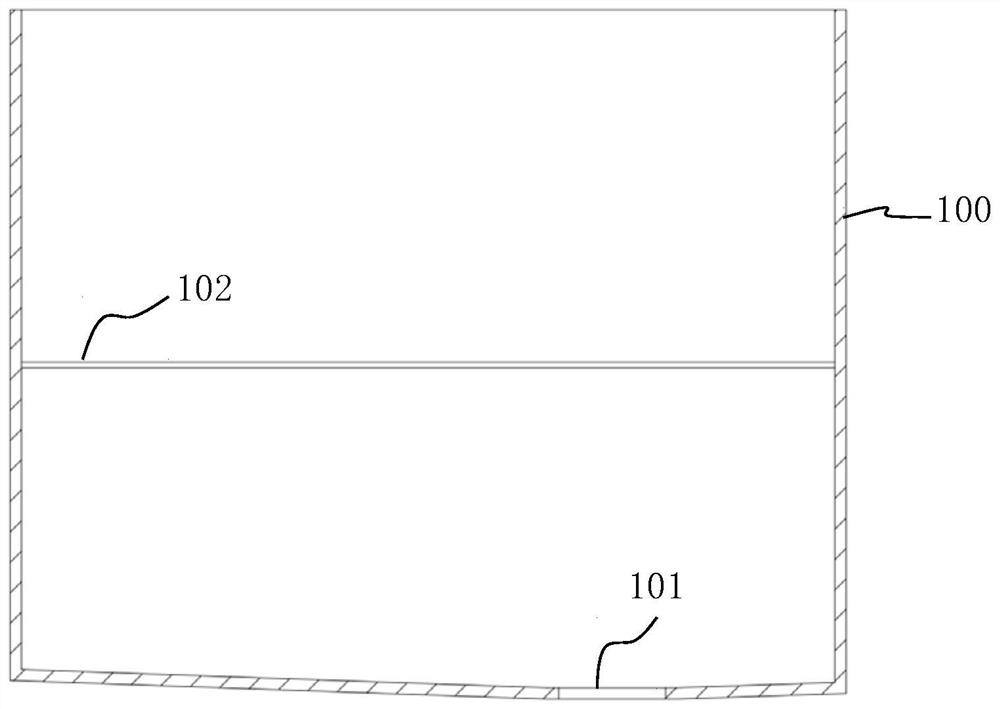

[0021] Both the outer tank body 100 and the inner tank body 200 are rectangular tank bodies. The inner tank body 200 is fixed in the outer tank body 100 , the top surface of the inner tank body 200 is slightly lower than the top surface of the outer tank body, and the bottom surface of the inner tank body 200 extends to the middle of the outer tank body 200 .

[0022] Wherein, the top of the outer tank body 100 is open, and the bottom has an inclined bottom surface inclined downward from the front end and the rear end respectively, the inclined bottom surface on the front end side has an inclined angle of 176°, and the inclined bottom surface on the rear end side has an inclined angle of 178°. A discharge port 101 is provided at the lowest position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com