Automatic assembling device for inner doors and rubber strips of dish washing machines

An automatic assembly device, dishwasher technology, applied in conveyors, winding strips, transportation and packaging, etc., can solve the problems of inaccurate placement of adhesive strips, low product consistency, and difficult to control the conveying process. To prevent the deformation or damage of the rubber strip, it is beneficial to the consistency of the product, and the effect of reducing the risk index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

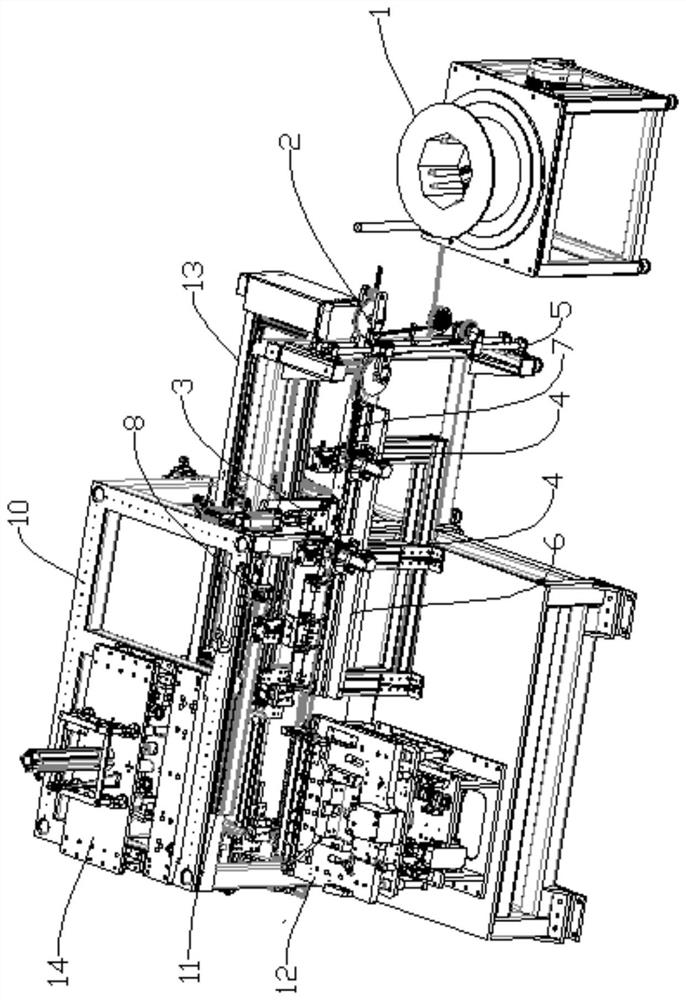

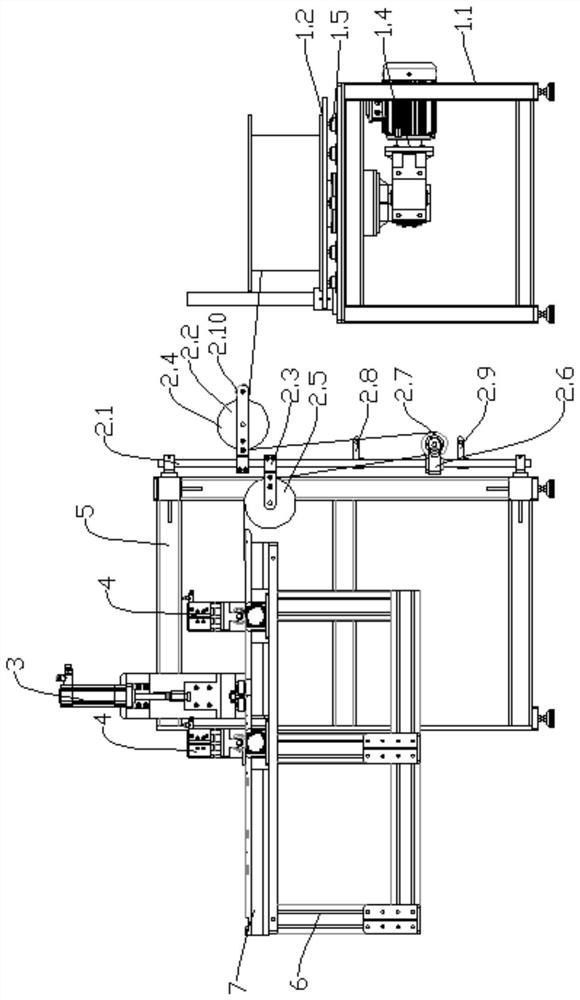

[0037] Such as figure 1 and figure 2 As shown, the present invention mainly comprises the unwinding mechanism 1 that realizes rubber strip unwinding, and the discharge end of unwinding mechanism 1 is provided with material storage mechanism installation frame 5, and storage mechanism installation frame 5 is provided with the storage that temporarily stores and expands rubber strip. Material mechanism 2. The material storage mechanism 2 discharge end is provided with feeding guide rail 7, is provided with in the feeding guide rail 7 and is used to accommodate the feeding groove that rubber strip passes through, and feeding guide rail 7 is fixed on the rubber strip guide rail installation frame 6, and rubber strip guide rail installation frame 6 is fixedly connected on Storage mechanism mounting frame 5 side.

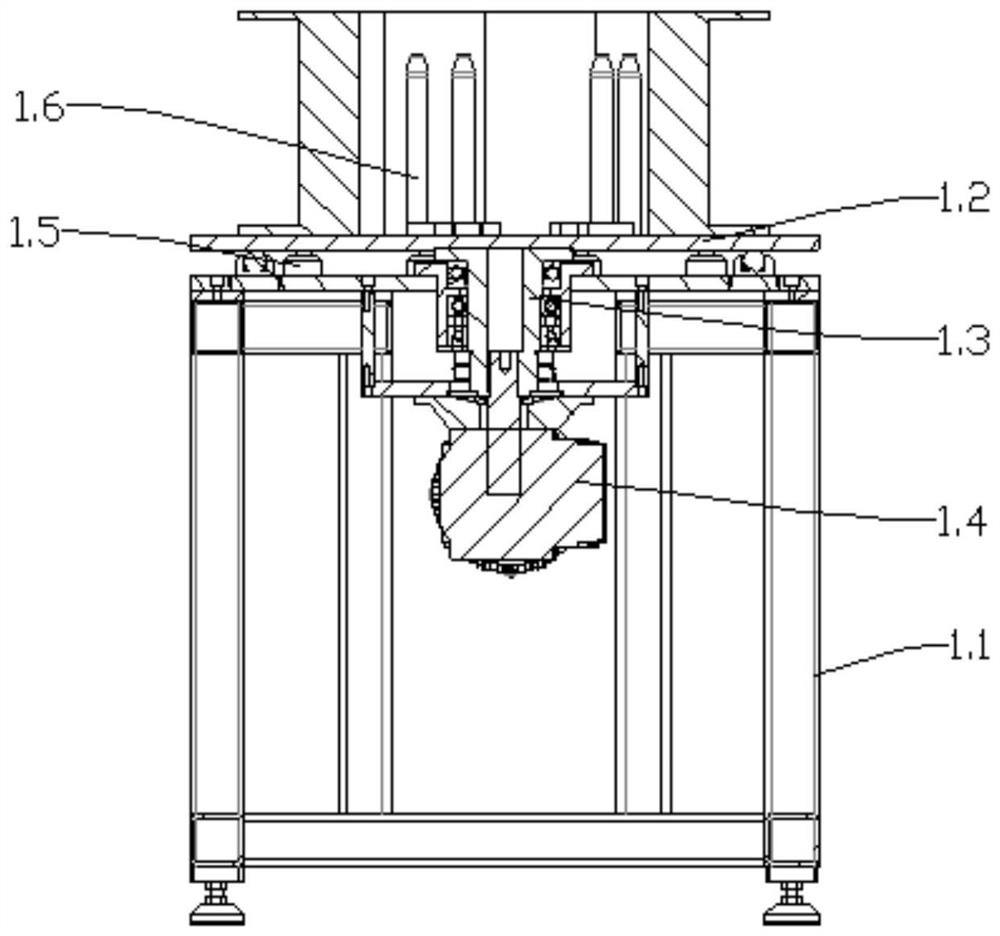

[0038] Such as image 3 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com