Reciprocating heating type pearl wool adhesion machine

A technology of pearl cotton and bonding machine, applied in the field of bonding machine, can solve the problems of poor bonding effect, insufficient bonding, and inability to heat the pearl cotton sheet evenly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

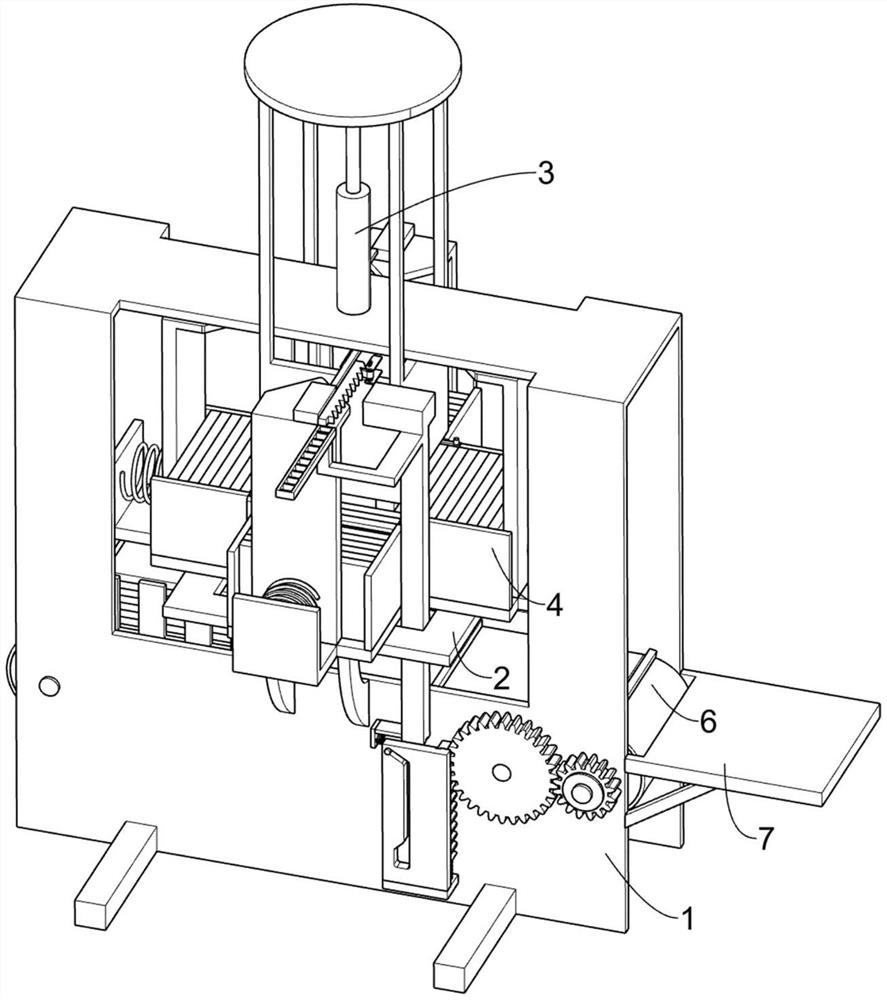

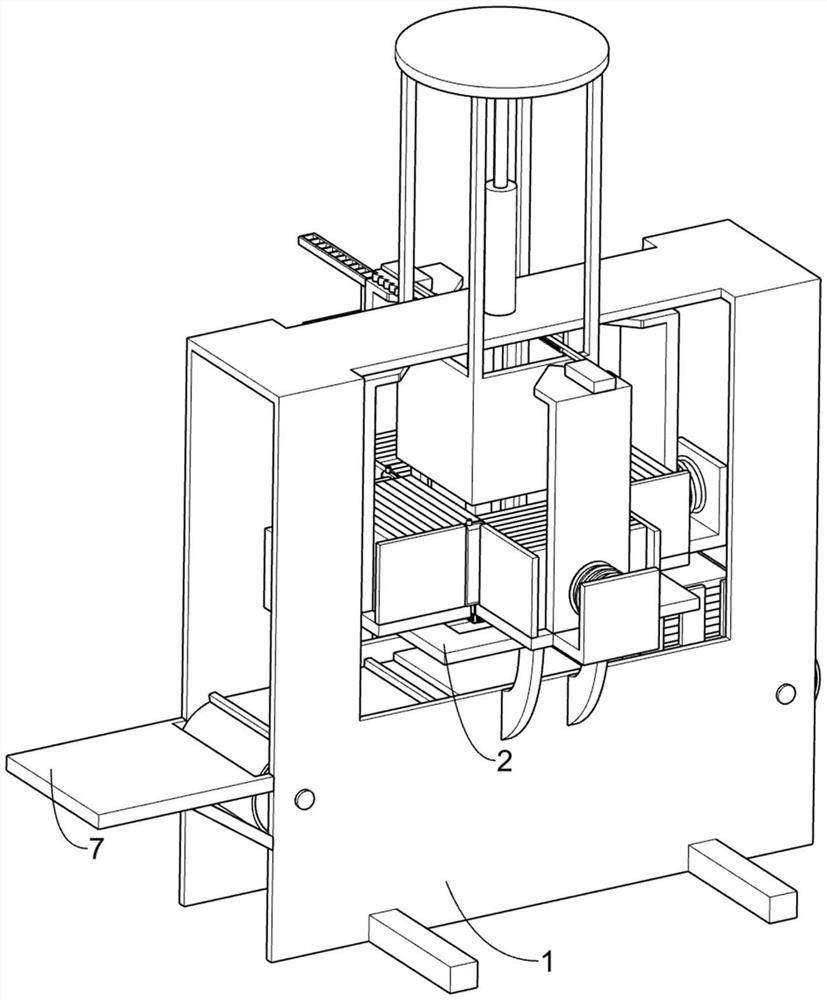

[0028] A reciprocating heating type pearl cotton bonding machine, such as Figure 1-2 As shown, it includes a first support frame 1, a second support frame 2, a transmission assembly 3, a side plate push assembly 4, an intermittent hot air blowing assembly 5 and a floor push assembly 6, and the first support frame 1 is fixedly connected with a second support Frame 2, the second support frame 2 is provided with a transmission assembly 3, the transmission assembly 3 is used to transport the bottom plate of the pearl cotton sheet, one side of the transmission assembly 3 is provided with a side plate push assembly 4, and the side plate push assembly 4 is used to push the heating The viscous pearl cotton sheet side panels move inwards for tight bonding, and the second support frame 2 is provided with an intermittent hot air blowing assembly 5, which is used to heat one side of the pearl cotton sheet plate. Viscosity, and then bonded with the pearl cotton sheet, the first support fr...

Embodiment 2

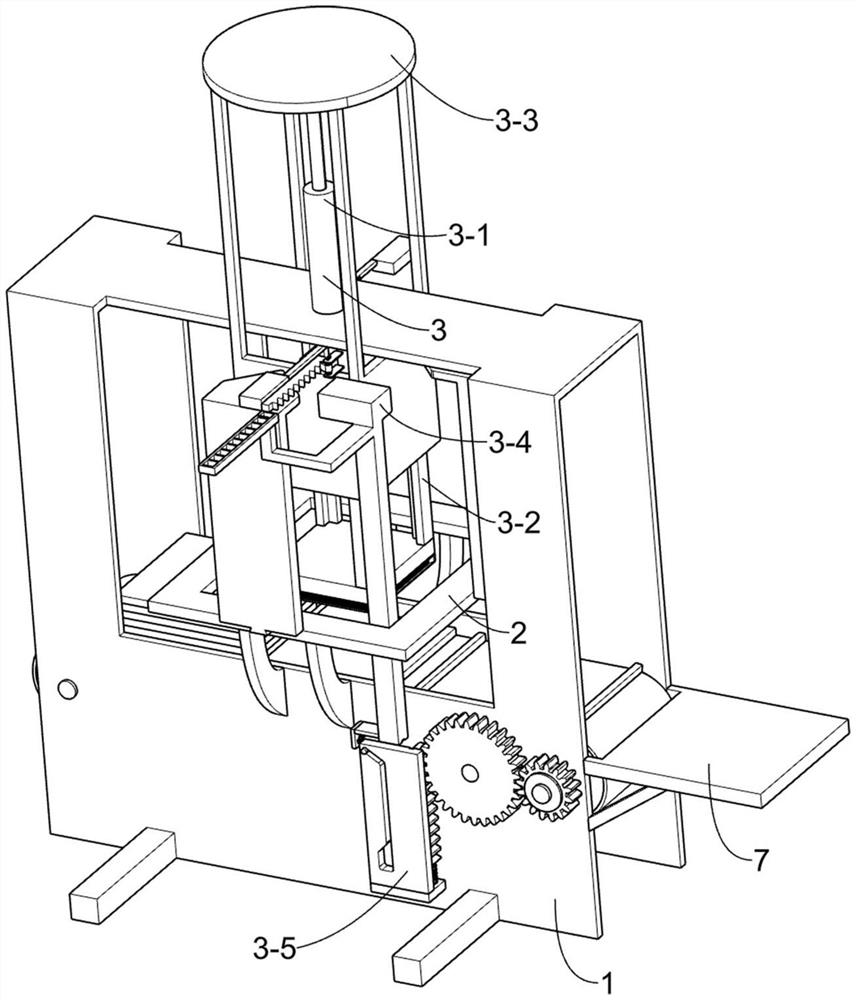

[0030] On the basis of Example 1, such as Figure 3-10As shown, the transmission assembly 3 includes an electric push rod 3-1, a side plate limit frame 3-2, a sliding push frame 3-3, a support frame with a wedge block 3-4, an L-shaped guide plate 3-5, a first Spring 3-6, band clamp slide block 3-7, second spring 3-8, band clamp slide rack 3-9, first transmission shaft 3-11, first spur gear 3-12, second transmission The shaft 3-13, the overrunning clutch 3-14 and the second spur gear 3-15, the electric push rod 3-1 is fixedly installed on the top of the first support frame 1, and the side plate limit frame 3 is fixedly connected to the first support frame 1 -2, the end of the electric push rod 3-1 away from the first support frame 1 is fixedly connected with a sliding push frame 3-3, and the lower side of the sliding push frame 3-3 is fixedly connected with a support frame 3-4 with a wedge block. The lower part of a support frame 1 is fixedly connected with an L-shaped guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com