Conductive ink and preparation method thereof

A conductive ink and ink technology, applied in the direction of ink, household utensils, applications, etc., can solve the problems of conductive filler aggregation and settlement, the impact of conductive ink conductivity, and increased economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

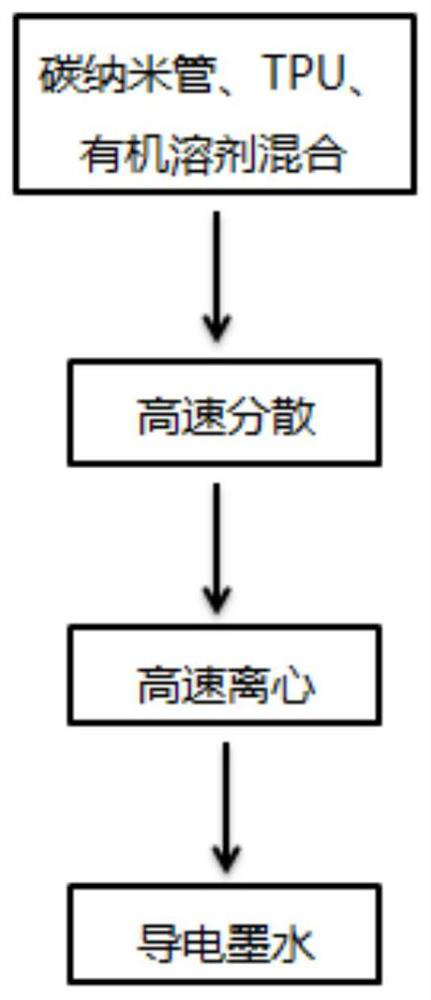

[0037] The preparation method of the conductive ink of the present embodiment is as figure 1 shown, including the following steps:

[0038] (1) Mix carbon nanotubes, thermoplastic polyurethane and an organic solvent, the concentration of carbon nanotubes in the mixed ink is 20mg / ml, and the carbon nanotubes are single-wall carbon nanotubes; the concentration of thermoplastic polyurethane is 20mg / ml, thermoplastic Polyurethane is aromatic polyurethane with a molecular weight of 10,000-500,000 Daltons; the organic solvent is N,N-dimethylformamide;

[0039] (2) Carry out high-speed dispersion treatment to the ink mixed in step (1), the rotating speed is 20000rpm, and the dispersion time is 3h;

[0040] (3) Perform high-speed centrifugation on the ink dispersed in step (2) at a speed of 10000 rpm for 5 minutes to remove carbon nanotubes not fixed by thermoplastic polyurethane to obtain the conductive ink.

Embodiment 2

[0042] The preparation method of the conductive ink of the present embodiment is as figure 1 shown, including the following steps:

[0043] (1) Mix carbon nanotubes, thermoplastic polyurethane and an organic solvent, the concentration of carbon nanotubes in the mixed ink is 50mg / ml, and the carbon nanotubes are single-wall carbon nanotubes; the concentration of thermoplastic polyurethane is 50mg / ml, thermoplastic Polyurethane is aromatic polyurethane with a molecular weight of 10,000-500,000 Daltons; the organic solvent is N,N-dimethylformamide;

[0044] (2) Carry out high-speed dispersion treatment to the ink mixed in step (1), the rotating speed is 30000rpm, and the dispersion time is 1h;

[0045](3) Perform high-speed centrifugation on the ink dispersed in step (2) at a speed of 5000 rpm for 10 minutes to remove carbon nanotubes not fixed by thermoplastic polyurethane to obtain the conductive ink.

Embodiment 3

[0047] The preparation method of the conductive ink of the present embodiment is as figure 1 shown, including the following steps:

[0048] (1) Mix carbon nanotubes, thermoplastic polyurethane and organic solvent, the concentration of carbon nanotubes in the mixed ink is 5mg / ml, and carbon nanotubes are single-wall carbon nanotubes; the concentration of thermoplastic polyurethane is 5mg / ml, thermoplastic Polyurethane is aromatic polyurethane with a molecular weight of 10,000-500,000 Daltons; the organic solvent is N,N-dimethylformamide;

[0049] (2) Carry out high-speed dispersion treatment to the ink mixed in step (1), the rotating speed is 10000rpm, and the dispersion time is 5h;

[0050] (3) Perform high-speed centrifugation on the ink dispersed in step (2) at a speed of 10000 rpm for 2 minutes to remove carbon nanotubes not fixed by thermoplastic polyurethane to obtain the conductive ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com