Formwork system for building cast-in-place shear wall and filler wall and construction method

A shear wall and infill wall technology, which is applied in the on-site preparation of building components, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve the problems affecting the total construction period and the turnover of formwork systems Problems such as low frequency and non-recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

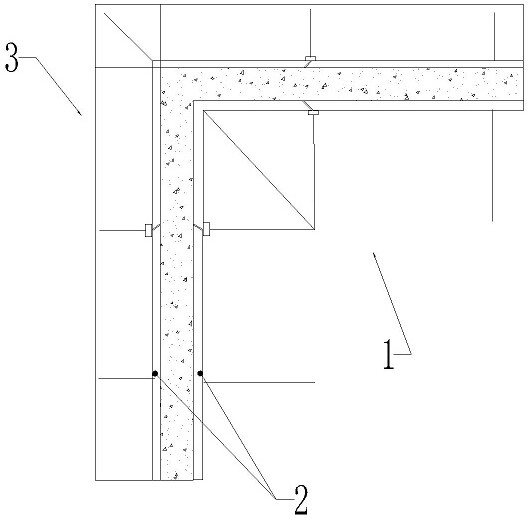

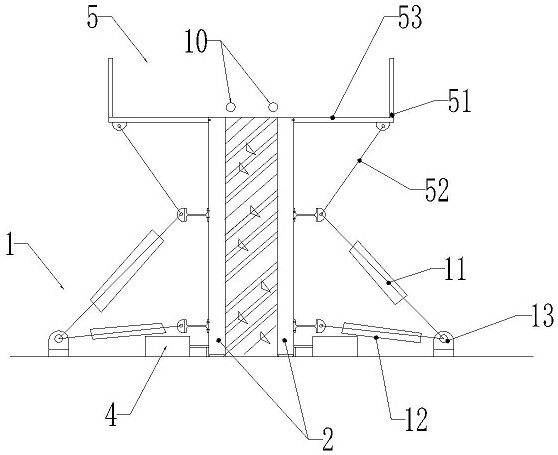

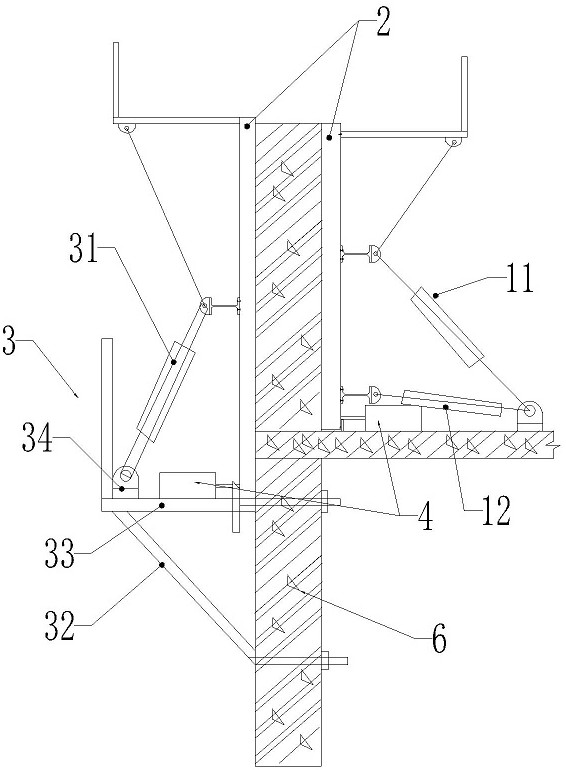

[0095] Such as Figure 1-11 As shown, the formwork system for building cast-in-place shear walls and infill walls includes formwork 2, first formwork support mechanism 1, second formwork support mechanism 3, concrete pouring platform mechanism 5, third formwork support mechanism 8, formwork Position monitoring mechanism 4, template verticality monitoring mechanism 9 and template cleaning mechanism.

[0096] Wherein, the first formwork support mechanism 1 is fixedly installed on the horizontal cast-in-place slab of the floor, and is used for supporting and positioning the formwork 2 on the horizontal cast-in-place slab of the floor.

[0097] The second template support mechanism 3 is fixedly installed on the outer wall of the vertical wall 6 for supporting and positioning the template 2; the vertical wall 6 is generally an outer wall.

[0098] The concrete pouring platform mechanism 5 is fixed on the upper end of the formwork 2, and is used for walking and operating standing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com