Tunnel energy dissipation supporting structure and construction method

A technology for supporting structures and tunnels, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as large impact, time-consuming and labor-intensive, and long-term occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

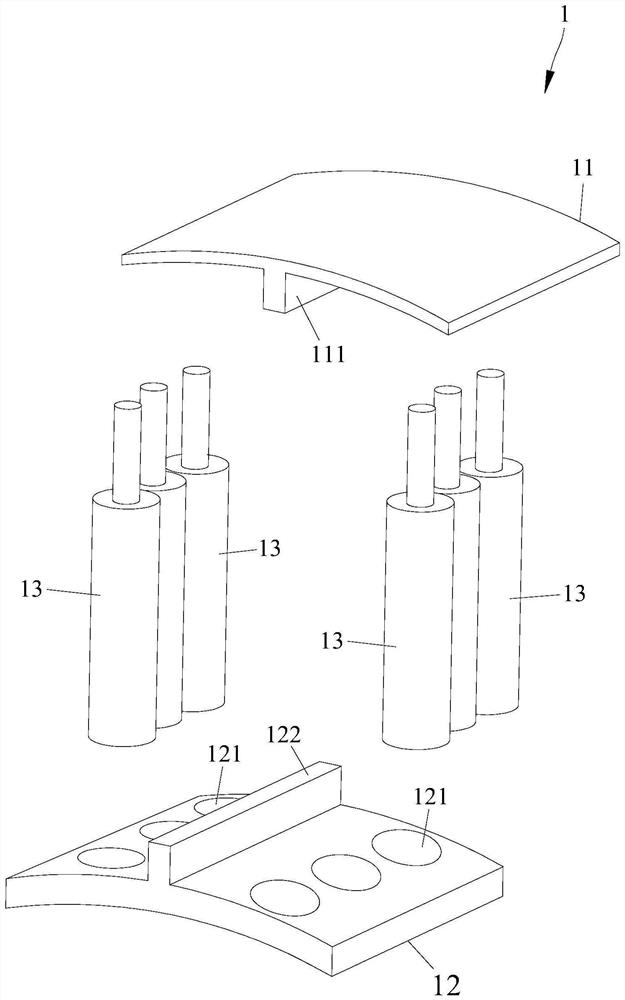

[0025] In this example, if figure 2 , Figure 5 As shown, the circumferential energy release device 2 includes a ball joint 23, a hollow ball seat 21 connected to one of the two circumferentially adjacent radial energy absorbing devices 1, and an elastic pad 22 arranged inside the hollow ball seat 21, The hollow ball seat 21 is provided with an avoidance hole 211 towards the area of the other of the two adjacent radial energy-absorbing devices 1 , and the ball hinge 23 includes a rod part 232 and a ball part 231 connected to one end of the rod part 232 The ball portion 231 is wrapped in the elastic pad 22 , and the end of the rod portion 232 away from the ball portion 231 protrudes through the escape hole 211 and is connected to the other of the two circumferentially adjacent radial energy-absorbing devices 1 . When the surrounding rock is deformed, the two rings move relative to the adjacent radial energy-absorbing device 1, and drive the ball part 231 of the ball joint 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com